Preparation method of ferrous sulfate coated sustained-release dropping pills

A technology of ferrous sulfate and sustained-release dropping pills, applied in sugar-coated pills, pill delivery, pharmaceutical formulations, etc., can solve the problem of not producing ferrous sulfate-coated sustained-release dropping pills, etc., and avoid the peak and valley phenomenon of blood drug concentration , good reproducibility, and the effect of reducing the number of doses and doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

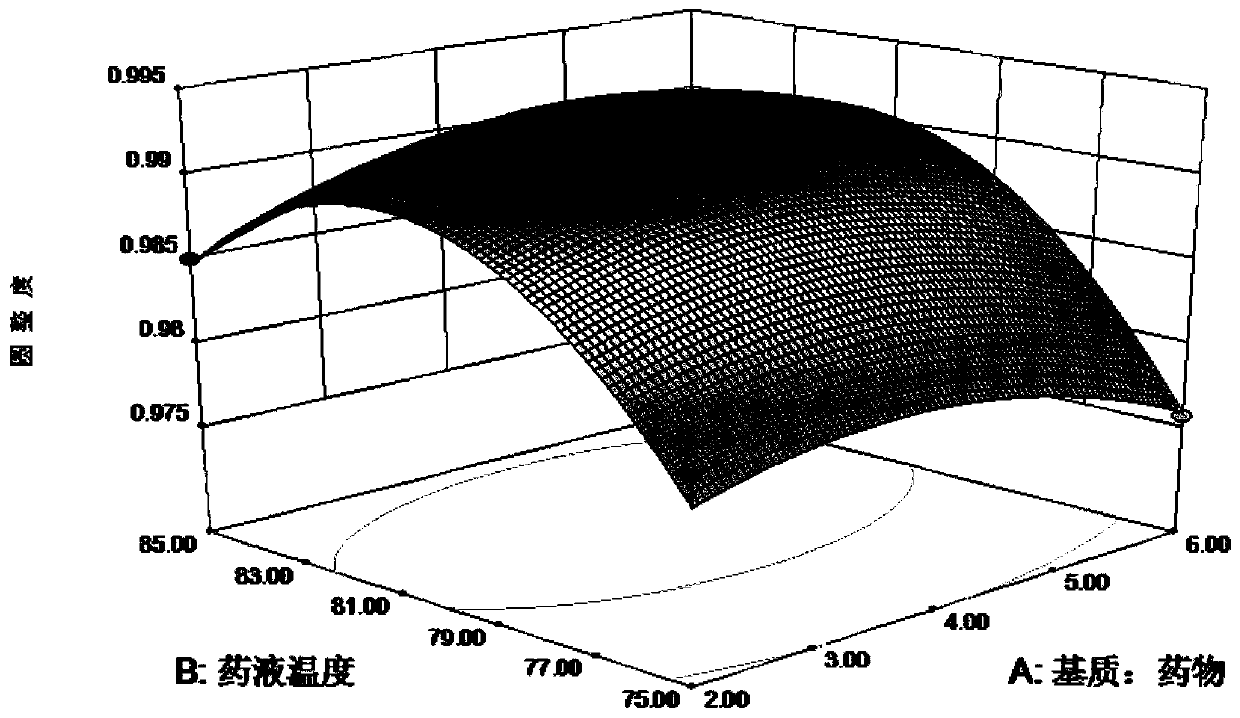

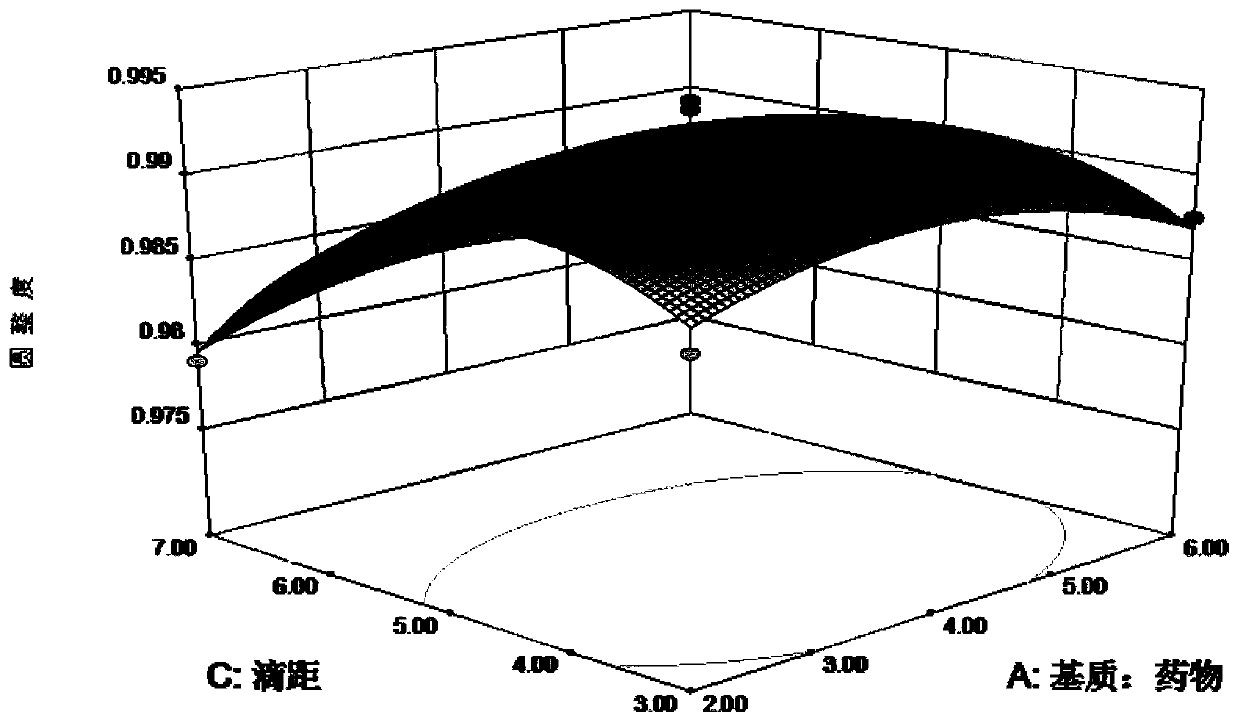

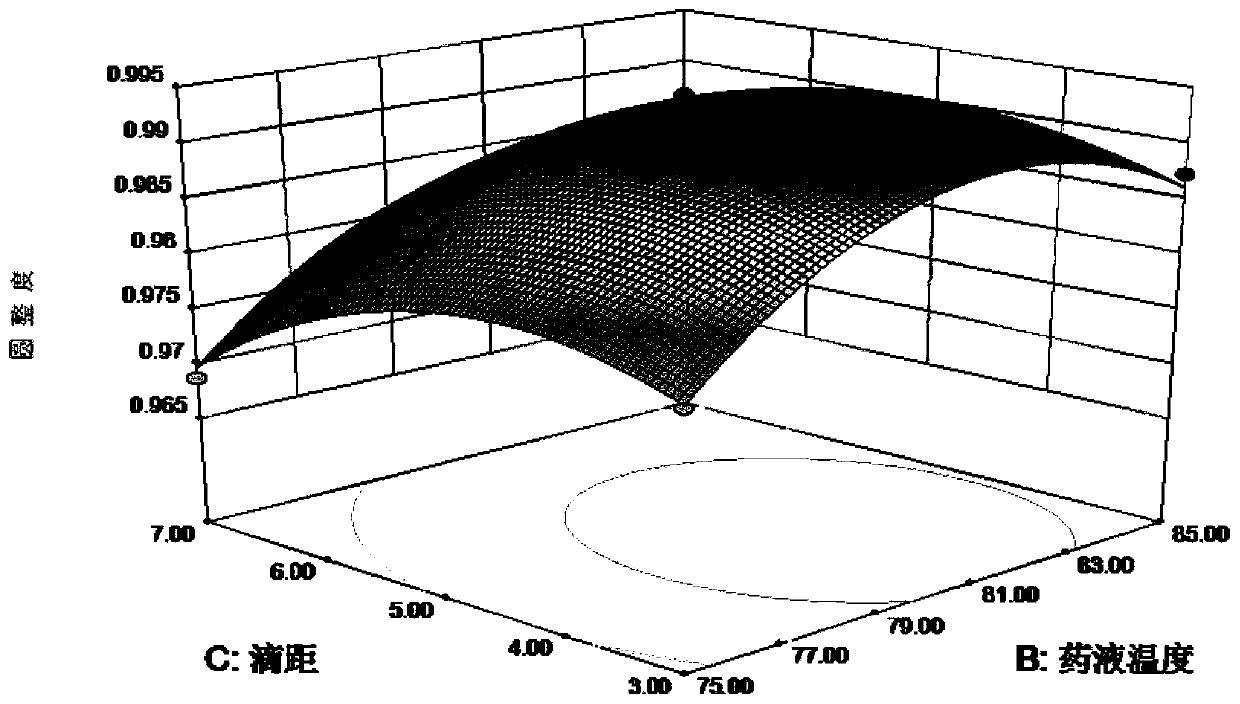

Image

Examples

Embodiment 1

[0051] A preparation method for ferrous sulfate coated sustained-release dropping pills, which comprises the following steps:

[0052] (1) Preparation of pellet core: Weigh PEG6000 and ferrous sulfate in a weight ratio of 2:1, heat and melt PEG6000 in a water bath, then add ferrous sulfate to PEG6000 in stages, stir and dissolve to obtain a medicinal solution, the temperature of the medicinal solution is Keep it at 75°C, then absorb the medicinal solution and drop it into the condensate at a drop distance of 3cm, form a pellet, take it out after standing for half an hour, wipe off the condensate, and dry it; the condensate is paraffin. The dripping speed of the liquid medicine is 20 drops / min, and the temperature of the lower half of the condensate is 5°C.

[0053] (2) Preparation of slow-release coating solution: Weigh the film-forming agent with a mass concentration of 1%, the plasticizer of 0.4%, and the pore-forming agent of 0.05%, and replenish to 100% by the solvent, and...

Embodiment 2

[0056] A preparation method for ferrous sulfate coated sustained-release dropping pills, which comprises the following steps:

[0057] (1) Preparation of pellet core: Weigh PEG6000 and ferrous sulfate in a weight ratio of 4:1, heat and melt PEG6000 in a water bath, then add ferrous sulfate to PEG6000 in batches, stir and dissolve to obtain a medicinal solution, and the temperature of the medicinal solution is Keep it at 80°C, then absorb the medicinal solution and drip it into the condensate at a drop distance of 5cm, form a pellet, take it out after standing for half an hour, wipe off the condensate, and dry it; the condensate is paraffin. The dripping speed of the liquid medicine is 20 drops / min, and the temperature of the lower half of the condensate is 5°C.

[0058] (2) Preparation of slow-release coating solution: Weigh the film-forming agent, 0.6% plasticizer, and 0.15% pore-forming agent with a mass concentration of 3%, then replenish to 100% by solvent, add the film-fo...

Embodiment 3

[0061] A preparation method for ferrous sulfate coated sustained-release dropping pills, which comprises the following steps:

[0062] (1) Preparation of pellet core: Weigh PEG6000 and ferrous sulfate in a weight ratio of 3:1, heat and melt PEG6000 in a water bath, then add ferrous sulfate to PEG6000 in stages, stir and dissolve to obtain a medicinal solution, the temperature of the medicinal solution is Keep it at 85°C, then absorb the medicinal solution and drop it into the condensate at a drop distance of 7cm, form a pellet, take it out after standing for half an hour, wipe off the condensate, and dry it; the condensate is paraffin. The dripping speed of the liquid medicine is 20 drops / min, and the temperature of the lower half of the condensate is 5°C.

[0063] (2) Preparation of slow-release coating solution: Weigh the film-forming agent with a mass concentration of 5%, the plasticizer of 0.8%, and the pore-forming agent of 0.25%, and then replenish to 100% by the solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com