Efficient evaporator for refining adiponitrile and adiponitrile refining process

An adiponitrile and evaporator technology, which is applied in the field of high-efficiency evaporator and adiponitrile refining process to prevent back-mixing, prevent liquid entrainment, and ensure high vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

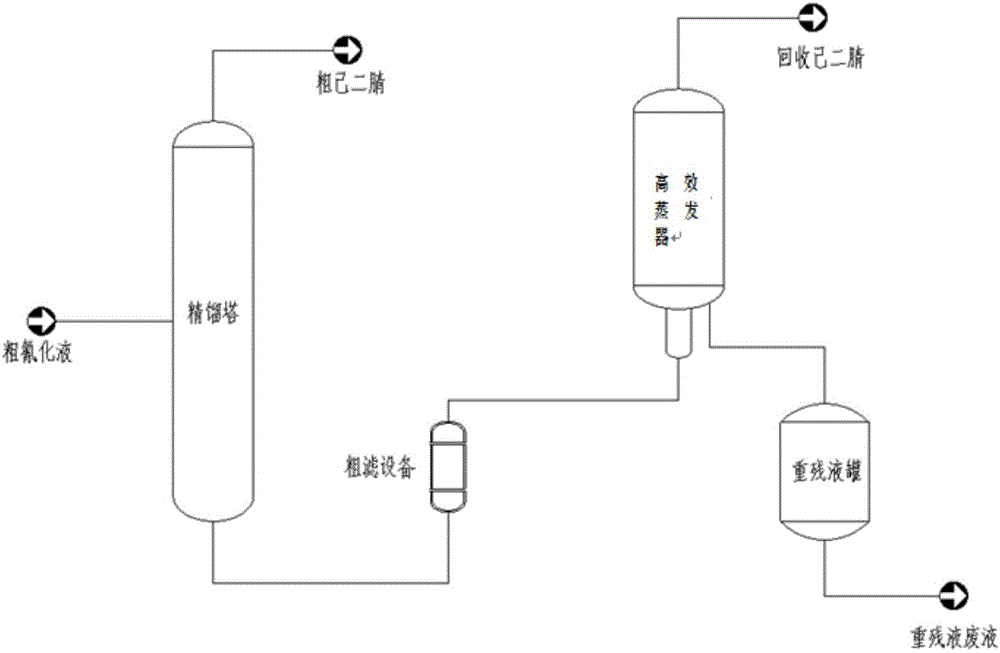

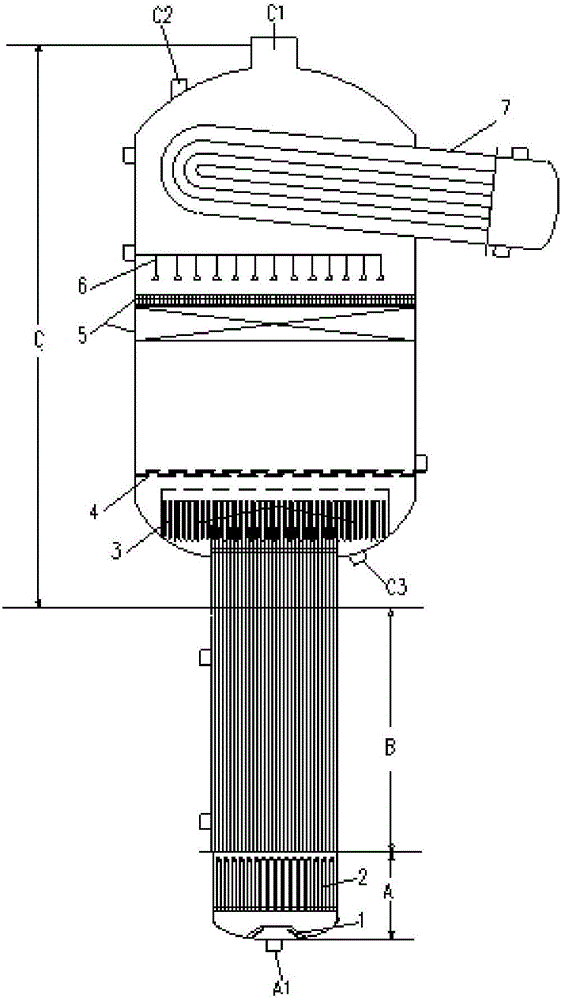

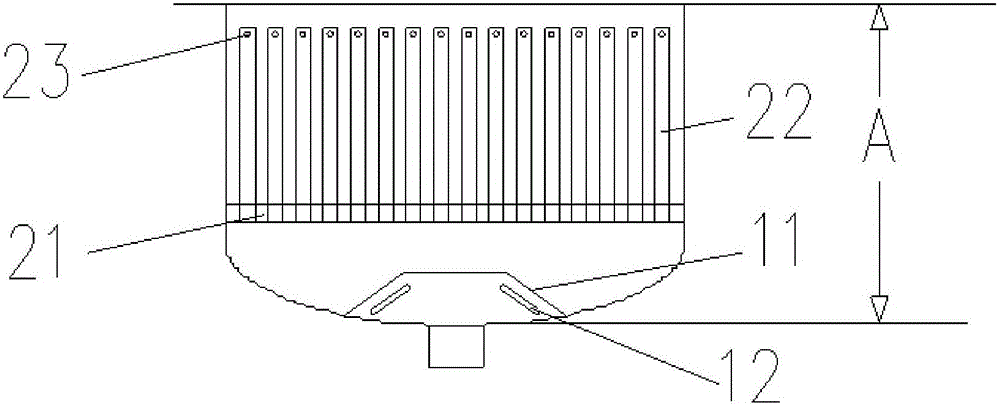

[0035]The crude cyanide solution from the two-step cyanidation process of adiponitrile enters the rectifying tower at 50332kg / h. In terms of mass percentage, the tower top contains 75-90% adiponitrile, and the content of by-products is 10-25%. The raffinate content is 0%, and the heavy raffinate content at the bottom of the tower is 100%. The heavy raffinate from the bottom of the rectification tower is separated from solid impurities by coarse filtration equipment, and then enters the high-efficiency evaporator; the operating temperature of the high-efficiency evaporator is controlled at 140-190°C, and the operating pressure is controlled at -99.9kPag-110kPag. Nitrile is recovered from the top of the evaporator, and the resulting heavy raffinate waste liquid enters the heavy raffinate tank;

[0036] The adiponitrile 6254kg / h of 100% purity is recovered at the top of the evaporator by sampling analysis; 1563kg / h of heavy raffinate waste liquid is obtained at the bottom of the ...

Embodiment 2

[0038] The crude cyanide solution from the two-step cyanidation process of adiponitrile enters the rectifying tower at 50332kg / h. In terms of mass percentage, the tower top contains 65-80% adiponitrile, and the content of by-products is 20-35%. The raffinate content is 0%, and the heavy raffinate content at the bottom of the tower is 100%. The heavy raffinate from the bottom of the rectification tower is separated from solid impurities through coarse filtration equipment, and then enters a high-efficiency evaporation system formed by two high-efficiency evaporators connected in series; The pressure is controlled at -99.9kPag ~ 110kPag, the separated adiponitrile is recovered from the top of the evaporator, and the obtained heavy raffinate waste liquid enters the heavy raffinate tank;

[0039] The adiponitrile 5248kg / h of 100% purity was recovered at the top of the last evaporator by sampling analysis; 2632kg / h of heavy raffinate was obtained at the bottom of the evaporator.

Embodiment 3

[0041] The crude cyanide solution from the two-step cyanidation process of adiponitrile enters the rectifying tower at 50332kg / h. In terms of mass percentage, the tower top contains 65-80% adiponitrile, and the content of by-products is 20-35%. The raffinate content is 0%, and the heavy raffinate content at the bottom of the tower is 100%. The heavy raffinate from the bottom of the rectification tower is separated from solid impurities through coarse filtration equipment, and then enters a high-efficiency evaporation system formed by three high-efficiency evaporators in series; The pressure is controlled at -99.9kPag ~ 110kPag, the separated adiponitrile is recovered from the top of the evaporator, and the obtained heavy raffinate waste liquid enters the heavy raffinate tank;

[0042] The adiponitrile 5431kg / h of 100% purity was recovered at the top of the last evaporator by sampling analysis; 2487kg / h of heavy raffinate was obtained at the bottom of the evaporator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com