Vacuum multi-layer insulating structure of low temperature thermal insulation paper for deep-cool storage container and matched pipelines

A low-temperature thermal insulation and multi-layer thermal insulation technology is applied in the field of low-temperature thermal insulation paper to achieve the effect of maintaining high vacuum degree, low transportation cost and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

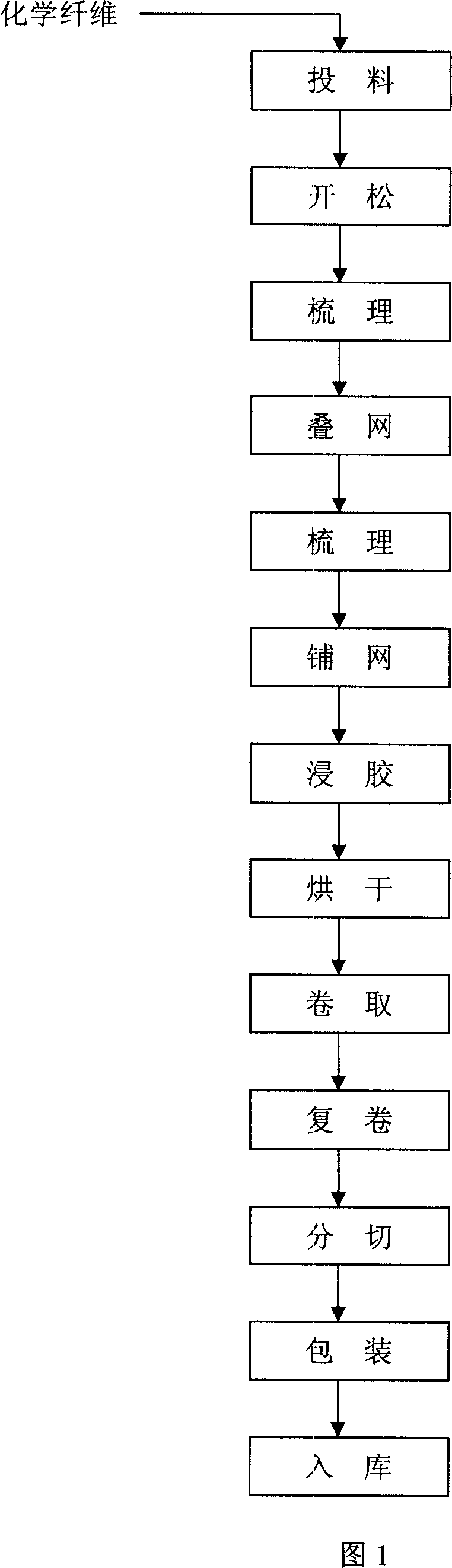

[0032] Example 1 Preparation of low-temperature insulation paper (reference figure 1 )

[0033] (1) Throw cotton-type viscose fiber with a fiber linear density of 1.67dtex onto the feeding net;

[0034] (2) After rough opening, the wind is sent to the opening machine for reopening;

[0035] (3) It is sent to the carding machine to be carded into a net;

[0036] (4) Fold the fiber web evenly by the laminating machine;

[0037] (5) Use a carding machine to card and spread into a uniform fiber web;

[0038] (6) Continuously pass the fiber web through an impregnation device containing 1.5% polyvinyl alcohol hydrosol, so that the fiber web is impregnated with the rubber material and then a certain amount of rubber material is squeezed out with a pressing roller;

[0039] (7) Use multiple drying cylinders to dry, and use a coiler to roll the finished product.

[0040] The above-mentioned finished products can also be put into storage after slitting and packaging.

[0041] The resultant product ...

Embodiment 2

[0042] Example 2 Preparation of low-temperature insulation paper

[0043] (1) Pour cotton-type polyester fiber with a fiber linear density of 1.2dtex onto the feeding net;

[0044] (2) After rough opening, the wind is sent to the opening machine for reopening;

[0045] (3) It is sent to the carding machine to be carded into a net;

[0046] (4) Fold the fiber web evenly by the laminating machine;

[0047] (5) Use a carding machine to card and spread into a uniform fiber web;

[0048] (6) Continuously pass the fiber web through an impregnation device containing 2.0% polyvinyl alcohol hydrosol, so that the fiber web is impregnated with the rubber material, and then a certain amount of rubber material is squeezed out with a pressing roller;

[0049] (7) Use multiple drying cylinders to dry, and use a coiler to roll the finished product.

[0050] The resultant product is determined to be 8~10g / m 2 , The thickness is 0.05~0.09mm. The low-temperature insulation paper is compounded with 0.006~0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com