Feed liquid filtering system for producing premna microphylla tofu

A technology of material-liquid filtration and Guanyin tofu, which is applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., can solve the problems of inability to filter, slow filtration speed, easy clogging of residues, etc., and achieve good passability, The effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

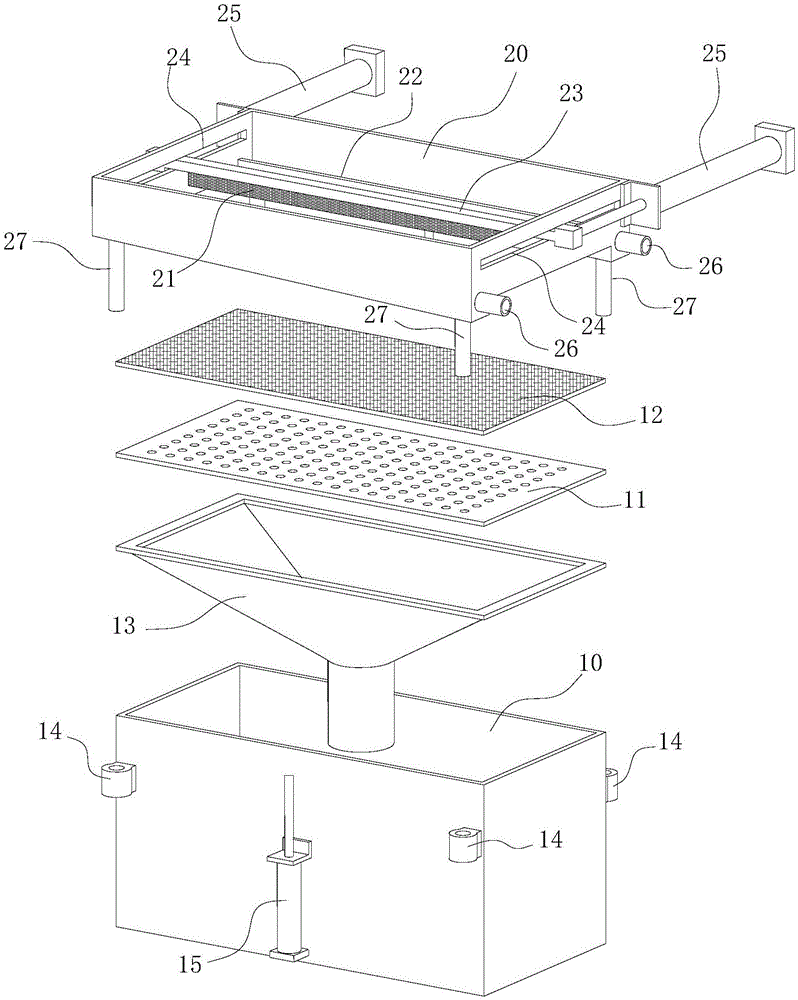

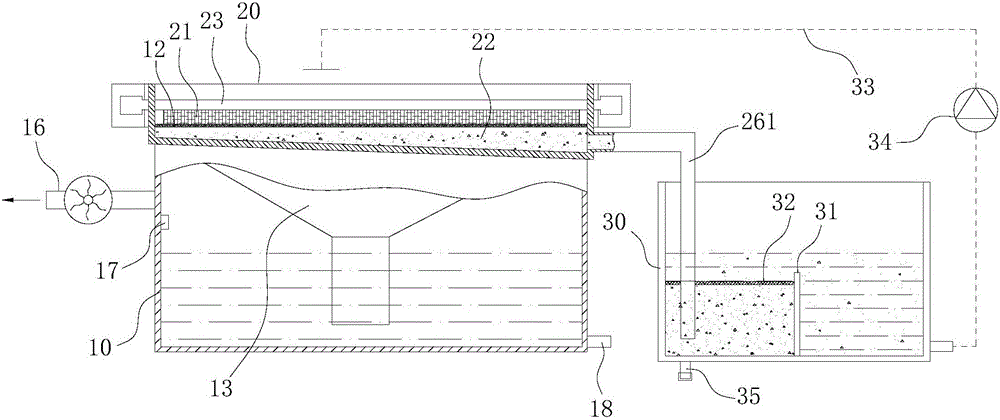

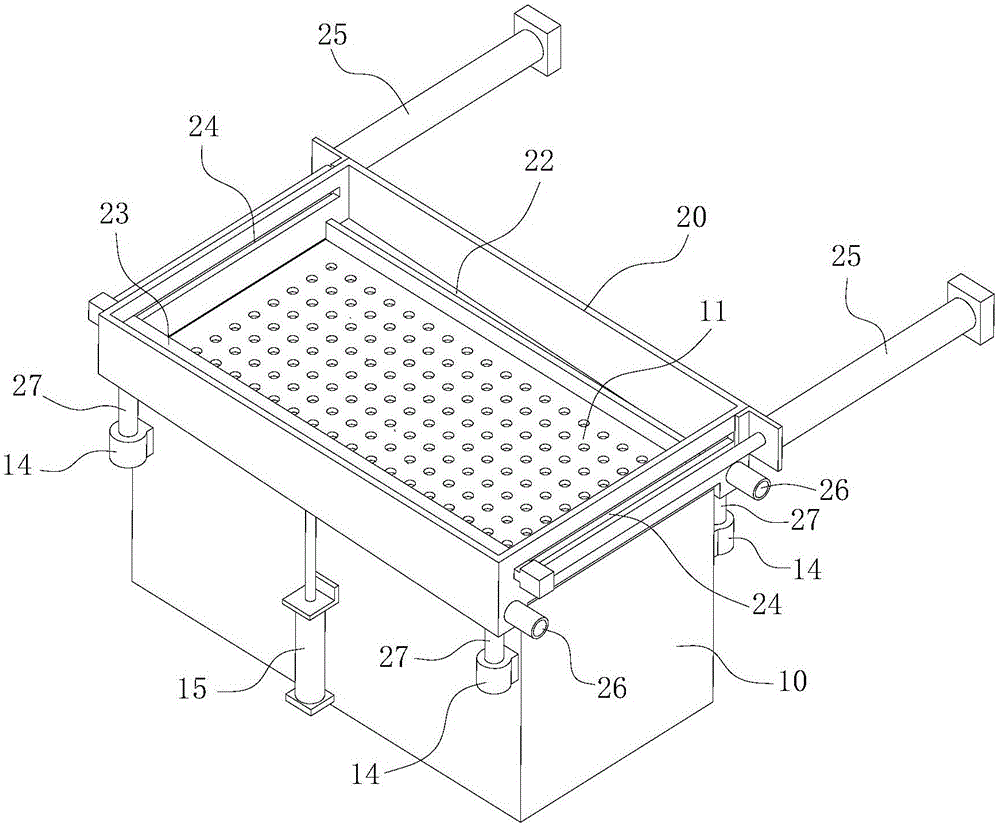

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as Figure 1-6 As shown, a material liquid filtration system for producing Guanyin bean curd comprises a filter plate 11, filter holes are evenly distributed on the filter plate 11, a filter cloth 12 is laid on the upper surface of the filter plate 11, and a liquid storage is arranged below the filter plate 11 Pool 10, the liquid storage pool 10 bottom is provided with liquid outlet 18; Also be provided with a movable frame 20 hollowed out in the middle part above the filter plate 11, the movable frame 20 is arranged around the filter plate 11, and forms a tank with the filter plate 11 , the movable frame 20 is arranged to reciprocate in the vertical direction, and the movable frame 20 is provided with a scraper 21 capable of reciprocating in the horizontal direction. When the movable frame 20 moves up and down, the scraper 21 and the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com