Turning method for tungsten-titanium target

A tungsten-titanium target material and turning technology, which is applied in the field of target materials, can solve the problems of not reaching the finished target material, fast wear of processing tools, and chipping of product edges and corners, and achieve good product quality, high turning quality, and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background, in the existing methods, the turning effect of the tungsten-titanium target product is not good. Moreover, tungsten-titanium, as the main component of cemented carbide materials, is widely used in cutting tools. In turn, it can be proved that the processing of tungsten-titanium targets is relatively difficult.

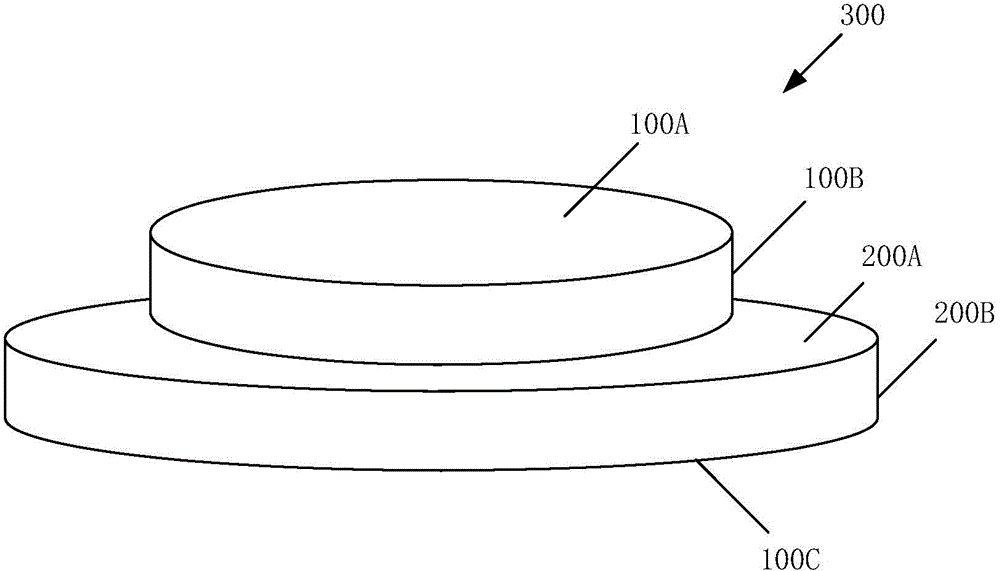

[0035] For this reason, the present invention provides a turning method of a tungsten-titanium target material. Firstly, the first tool is used to perform the first turning of the product, and then the back plate is processed, and then the second tool is used to perform the second turning of the product, and the second The included angle of the cutting edge of the tool is smaller than the included angle of the cutting edge of the first tool, and the included angle of the two tools is specially selected to ensure high turning quality of the final product.

[0036] In order to make the above objects, features and advantages of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com