Rotary drum turning and clamping device for electric locomotive position change-over switch

A technology for transfer switches and electric locomotives, applied in positioning devices, clamping devices, clamping, etc., can solve problems such as inability to guarantee roughness requirements, irregular drum structure, and difficult processing, so as to ensure contact performance and reliable operation performance, improve turning quality, and optimize the effect of turning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

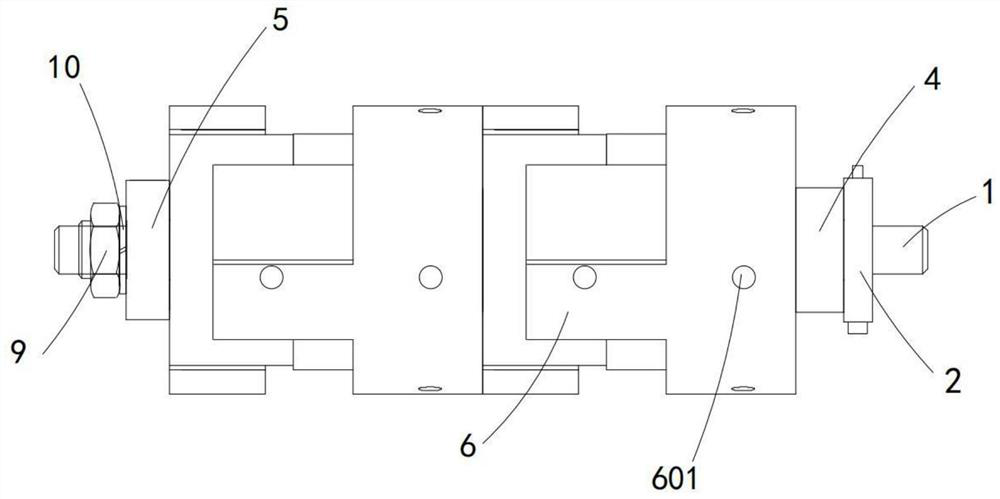

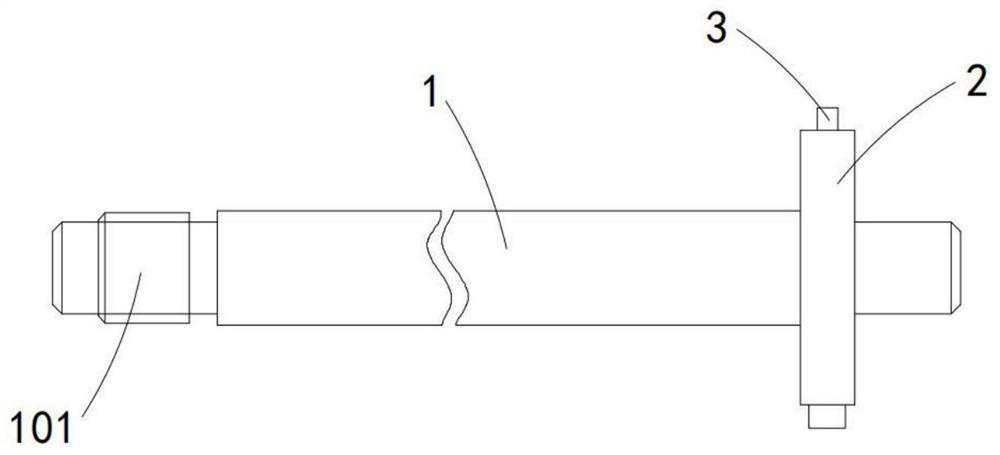

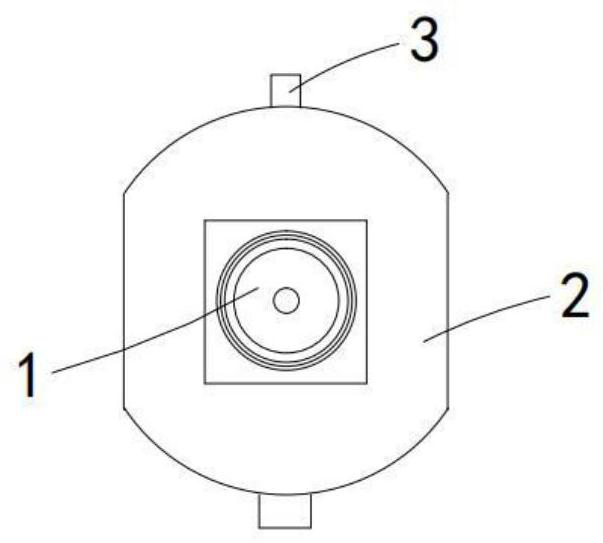

[0023] like Figure 1 to Figure 3 As shown, a kind of electric locomotive position conversion switch drum turning clamping device according to the present invention adopts the technical solution that includes an auxiliary clamping main shaft 1, and the auxiliary clamping main shaft 1 is clamped and connected with the turning machine tool. One side of the auxiliary clamping main shaft 1 is detachably connected to the limit ring 2, and the outer side of the auxiliary clamping main shaft 1 is sequentially interspersed with a plurality of drums 6, and the other side of the auxiliary clamping main shaft 1 is connected with a hexagonal Thin nut 10, the auxiliary clamping spindle 1 assists in clamping a plurality of rotating drums 6 connected to a lathe for turning and processing the outer ring of the rotating drum 6, and first retaining rings are arranged on both sides of the plurality of rotating drums 6 4 and the second retaining ring 5, the first retaining ring 4 and the second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com