Continuous curing method and system for programmed carbon dioxide curing building material products

A carbon dioxide and building material technology, applied in chemical instruments and methods, separation methods, manufacturing tools, etc., can solve problems such as poor utilization effect, reduced utilization efficiency, and gas waste, so as to improve effective utilization, reduce content, and realize flexible The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

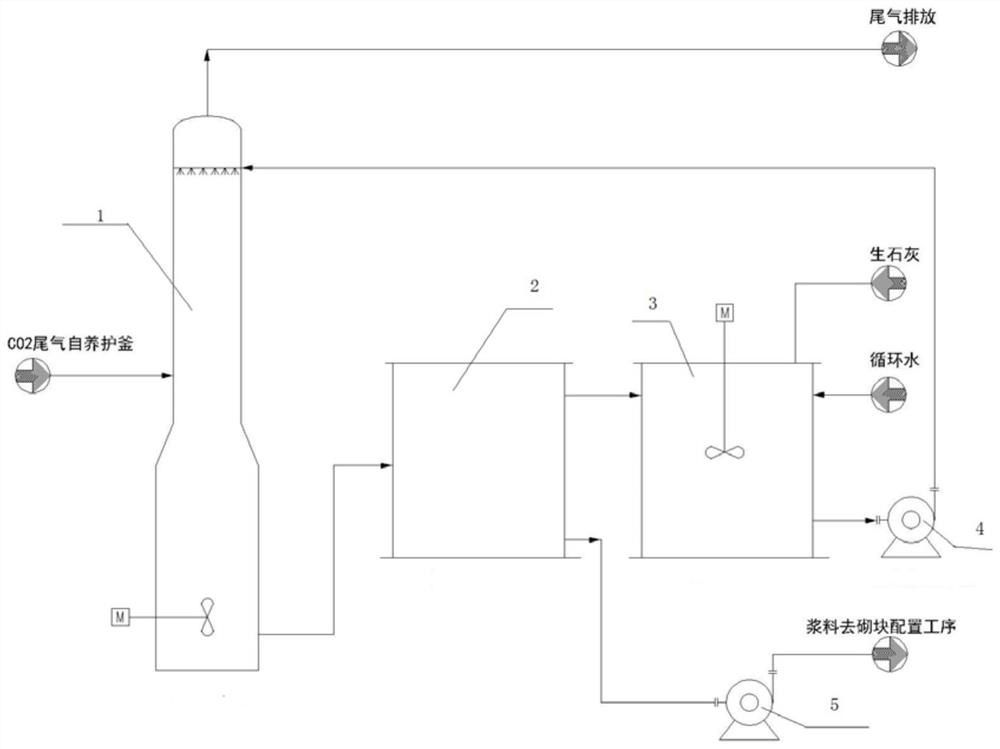

[0111] In this example, 300,000 m 3 / year aerated concrete block production plant as an example, carry out CO 2 Mineralization curing process description.

[0112] CO 2 The main raw materials required for the maintenance of building materials products include cement, fly ash, blast furnace slag, quicklime, gypsum powder, foaming agent, and stabilizer.

[0113] After batching, stirring, pouring, pre-curing, demoulding, cutting and other processes, the raw materials are sent to the curing kettle through the conveyor track for CO treatment. 2 conservation.

[0114] The specifications, models and product quality of the building materials products prepared in this example follow the requirements of the "GB / T11968-2020" standard.

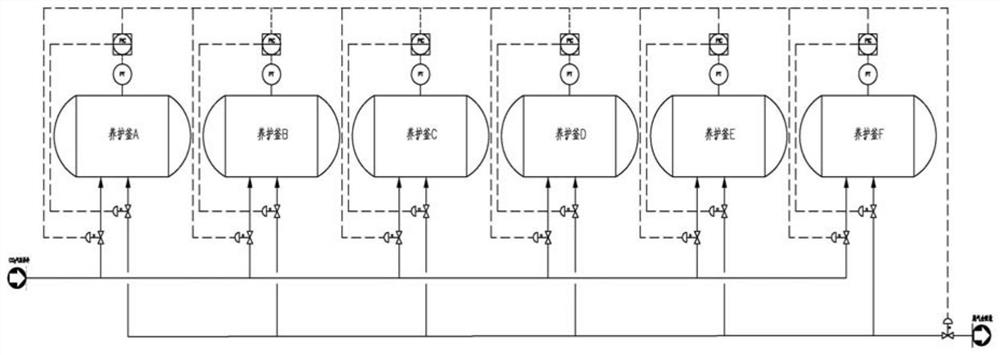

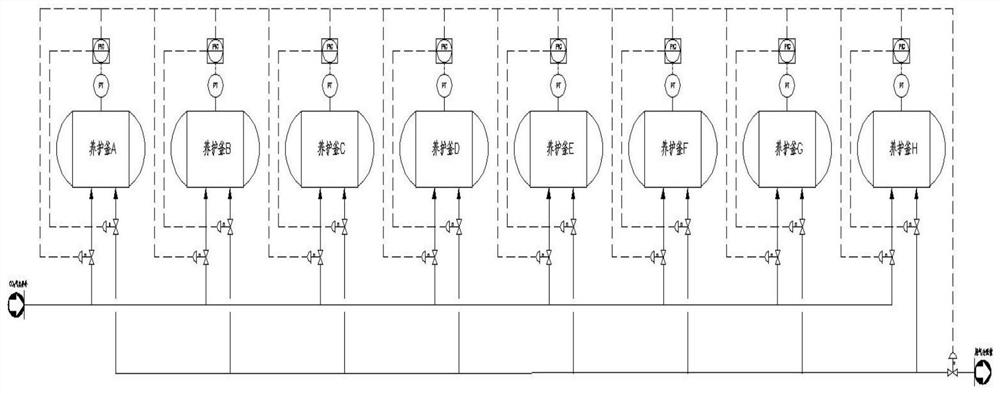

[0115] CO 2 In the mineralization curing stage, a total of 8 curing kettles are equipped, and the effective curing time of the curing kettles is 8 hours. 2 The gas source pressure is 1MPaG, and the curing kettle adopts the single-kettle independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com