Hydraulic spinning underwater pressure double drill trepanning device

A hydraulic and water inlet technology, used in boring/drilling, drilling/drilling equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

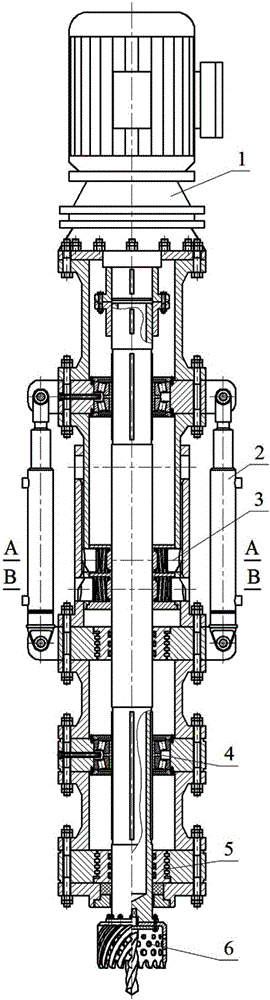

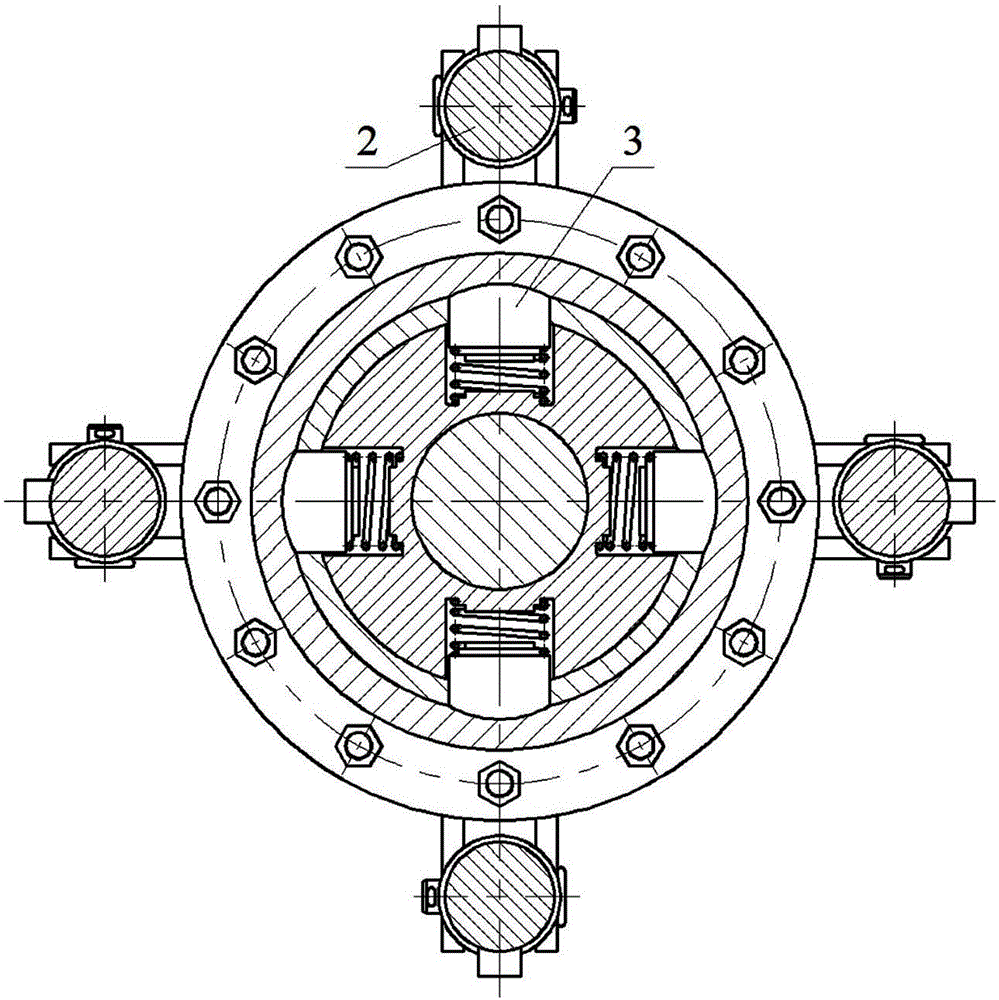

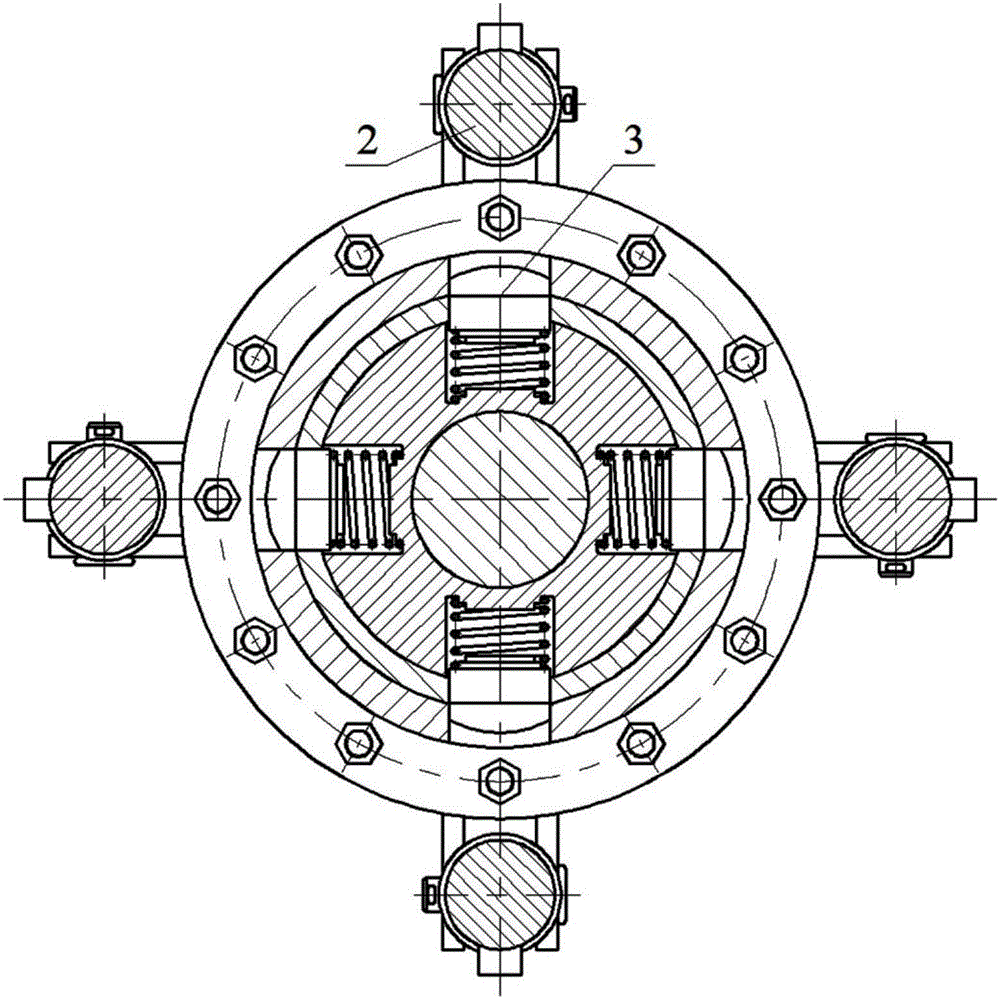

[0035] exist Figure 1 ~ Figure 3 Among them, the hydraulic spin-inlet underwater double-drill drilling device with pressure consists of a drilling assembly 1, a hydraulic feed system 2, a bidirectional stopper 3, a self-centering device 4, a sealing assembly 5, a double drilling tool 6 and Opening control system composition. Before the underwater pressurized double drill drilling device is assembled, the support cylinder of the drilling assembly 1, the base cylinder of the bidirectional stopper 3, the centering body of the self-centering device 4 and the outer surface of the main part of the sealing assembly 5 Carry out spray paint anticorrosion treatment respectively. When the underwater pressurized double-drill drilling device is assembled, the lower self-centering device 4 and sealing assembly 5 are sequentially inserted into the hollow drill pipe of the drilling assembly 1, and the guide pattern of the drilling assembly 1 is ensured. The precise fit between the key and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com