Ceramic woodworking tool

A technology of ceramic knives and knives, which is applied in the field of wood and wood composite material cutting, can solve the problems of rough cutting surface, fiber tearing, poor cutting quality, etc., so as to reduce roughness, increase life, and improve cutting The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

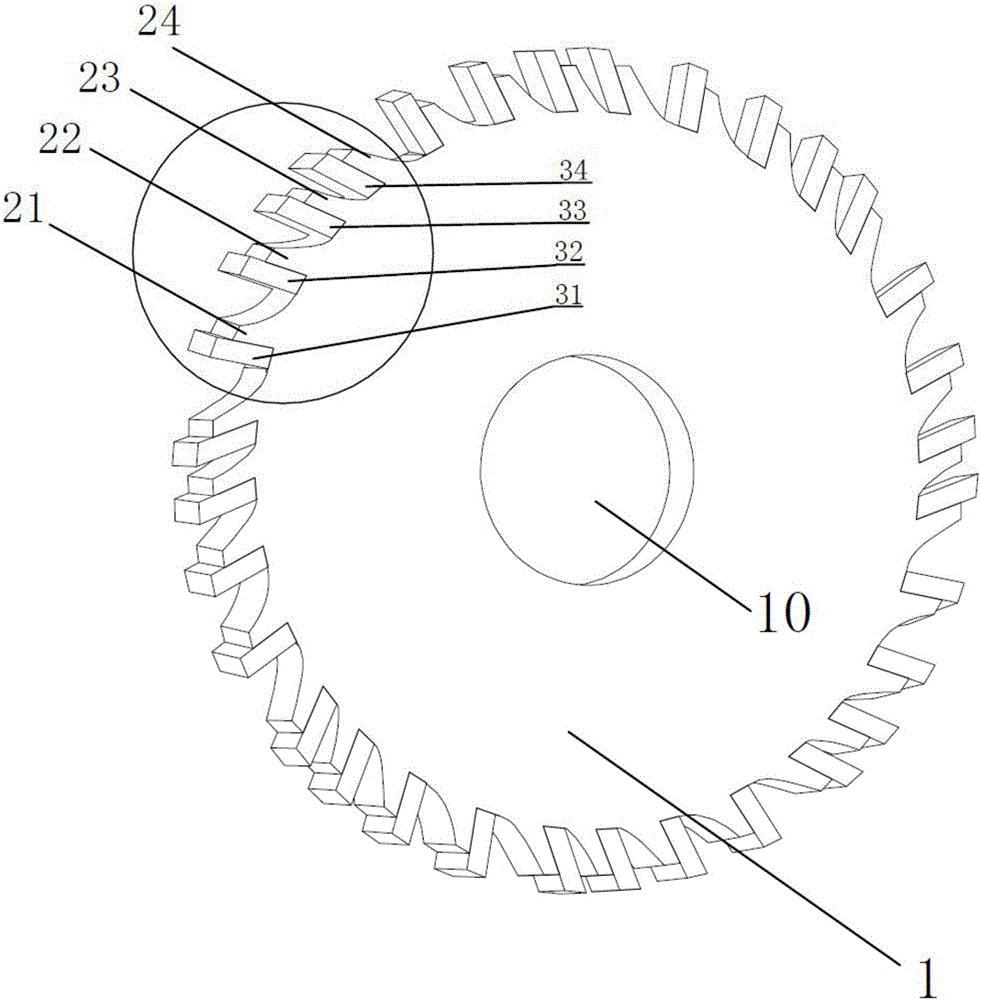

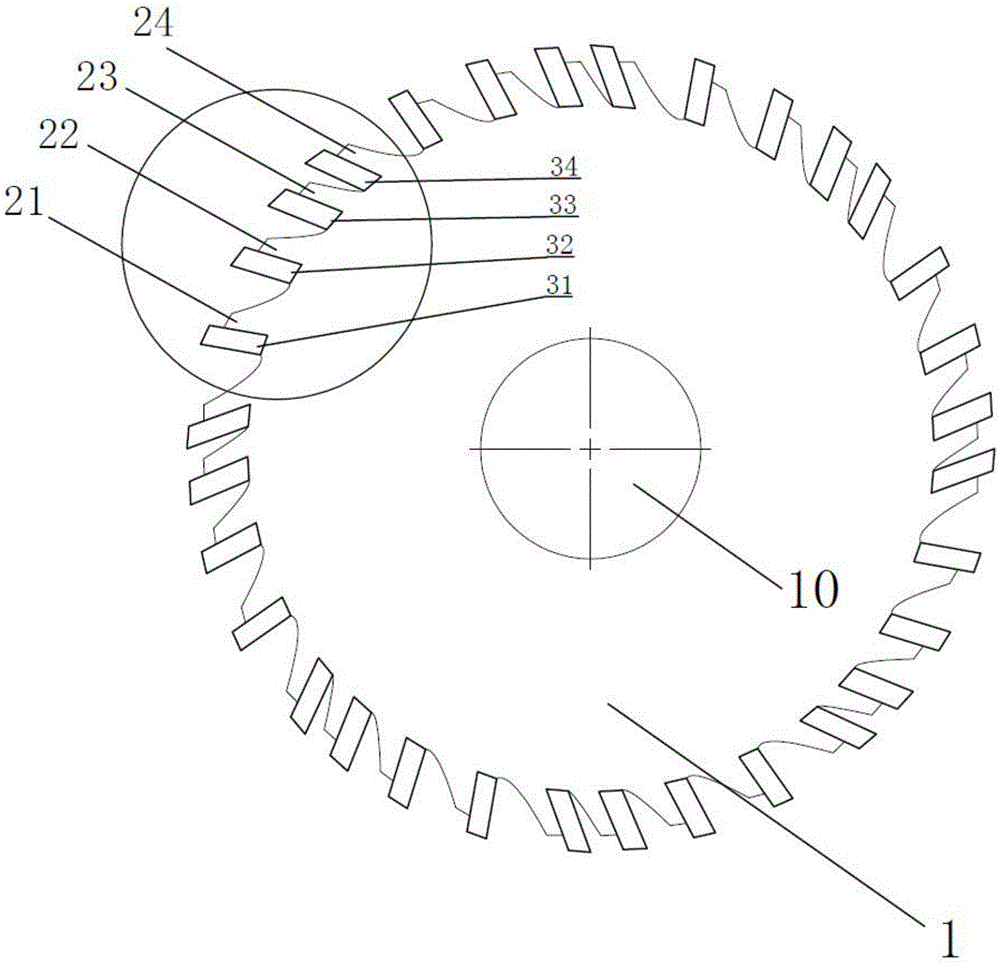

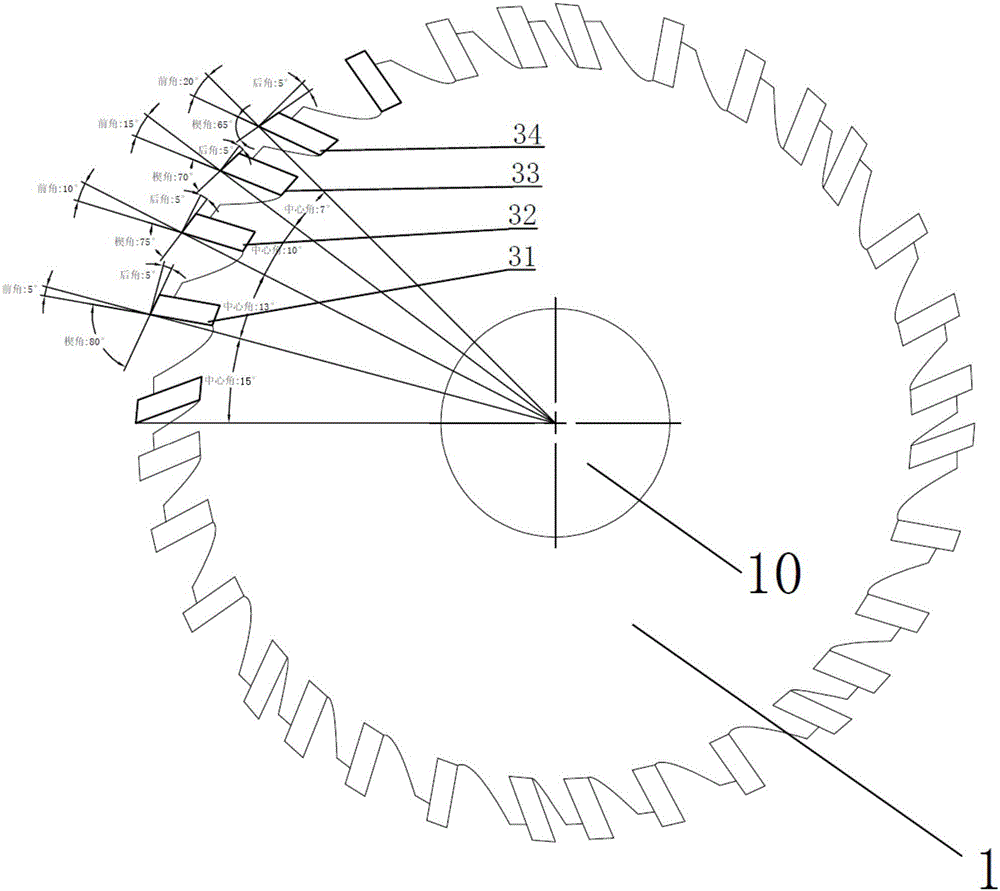

[0036] Such as Figure 1-8 As shown, the present invention provides a specific embodiment of a ceramic woodworking cutter, which includes a cutter body 1 and a central axis hole 10 in the cutter body 1, wherein: the cutter body 1 is a No. 45 steel cutter body. On the outer ring of the cutter body 1, there are 8 spiral ceramic cutter tooth groups with a center-symmetrical structure. The central angle of each spiral ceramic cutter tooth group is 45°. In any spiral ceramic cutter tooth group, there are four ceramic The cutter tooth holder and the four ceramic cutter teeth are respectively fixed on the four ceramic cutter holders;

[0037] Such as Figure 1~4 Shown in 2: The four ceramic tooth holders are ceramic tooth holder I21, ceramic tooth holder II22, ceramic tooth holder III23 and ceramic tooth holder IV24, and the four cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com