Mineral powder material increase manufacturing process and device

A mineral powder and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of slow curing and molding speed and high manufacturing cost, and achieve the effect of solving high cost, reducing difficulty and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

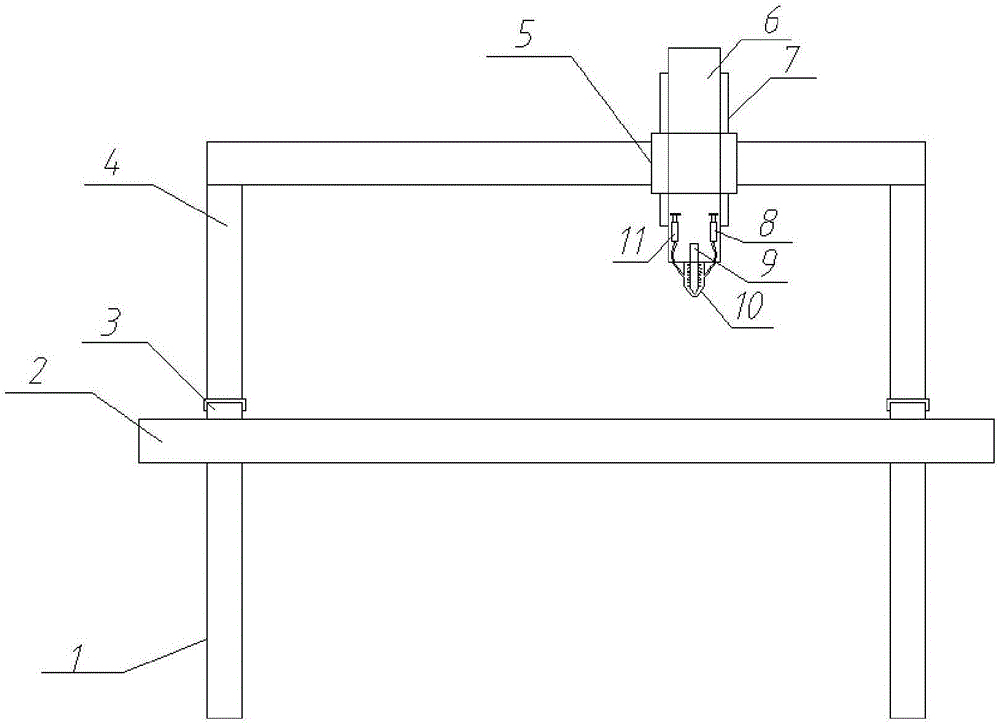

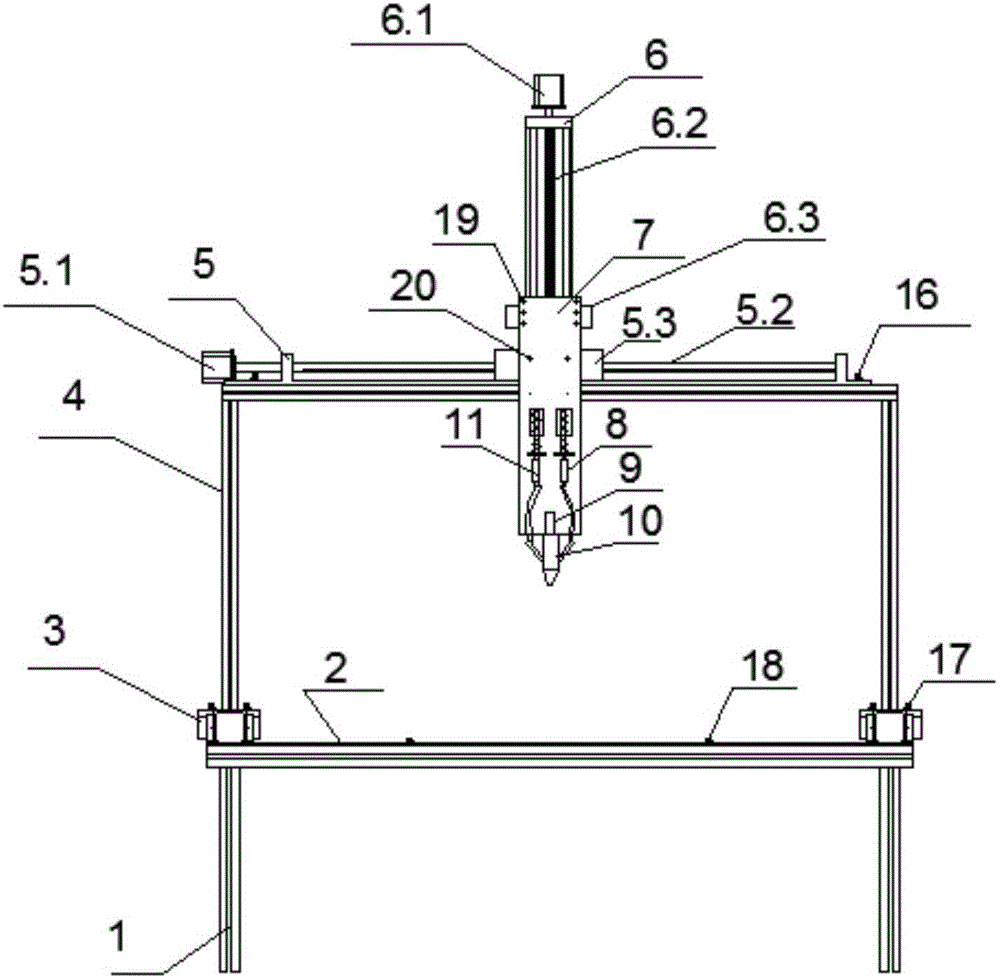

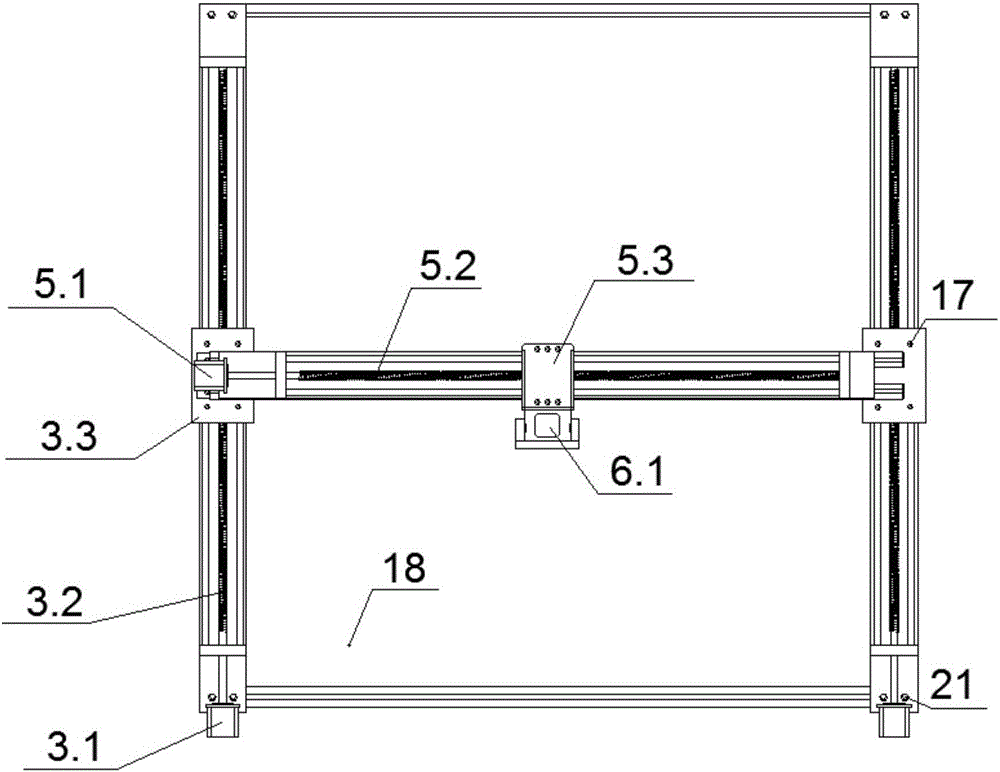

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

[0026] The mineral powder additive manufacturing process provided by the present invention comprises the following steps:

[0027] (1) Establish a solid three-dimensional model that requires additive manufacturing, and slice the model with a thickness of 0.1mm. The contour line of each layer of slice is the powdering trajectory of additive manufacturing;

[0028] (2) Lay the mineral powder according to the powder spreading track, and add binder and catalyst to the mineral powder at the same time, so that the mineral powder, binder and catalyst are mixed with each other during the falling process and laid on the manufacturing platform along the powder spreading track Above, the binder is water glass solution, the mass ratio of mineral powder to binde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com