Multi-station rotary forming machine

A molding machine and multi-station technology, applied in the fields of injection blowing or injection stretch blowing plastic bottle manufacturing equipment and multi-station rotary molding machines, can solve the problems of unstable up and down operation, complicated mechanism setting, complicated working process, etc. Achieve the effect of saving energy consumption, increasing the mold layout space, and saving cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

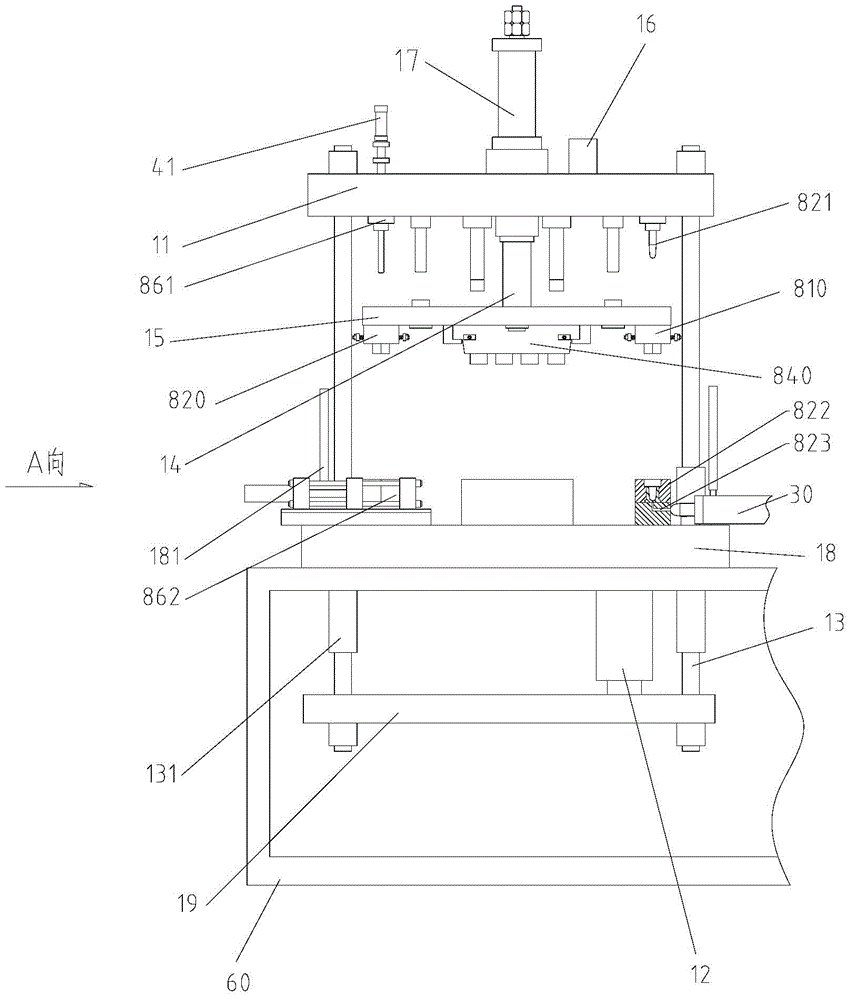

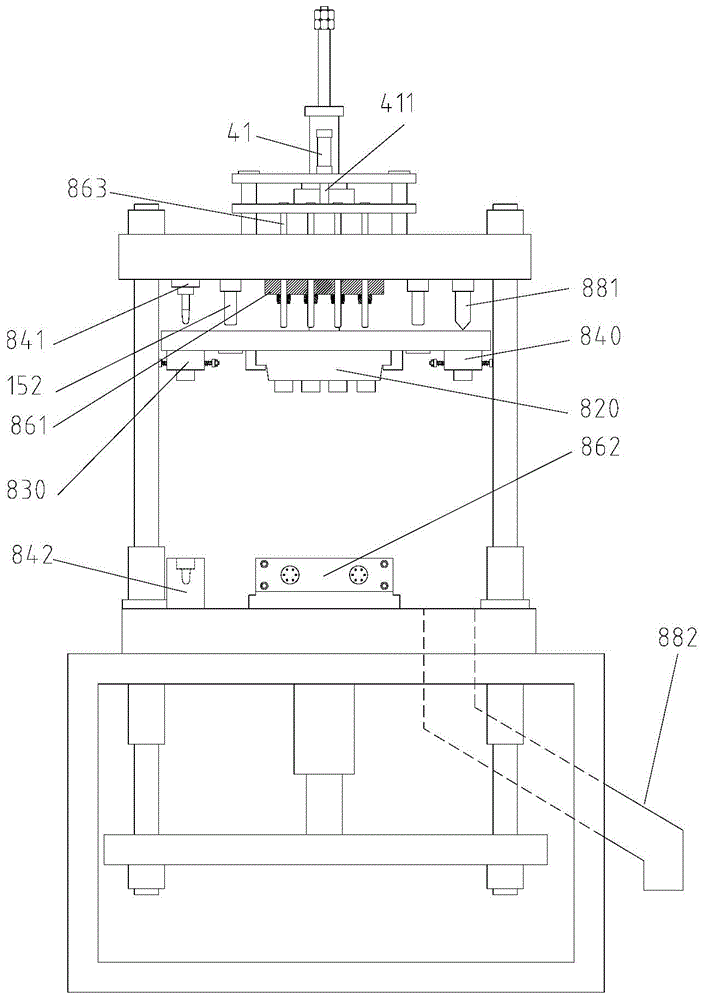

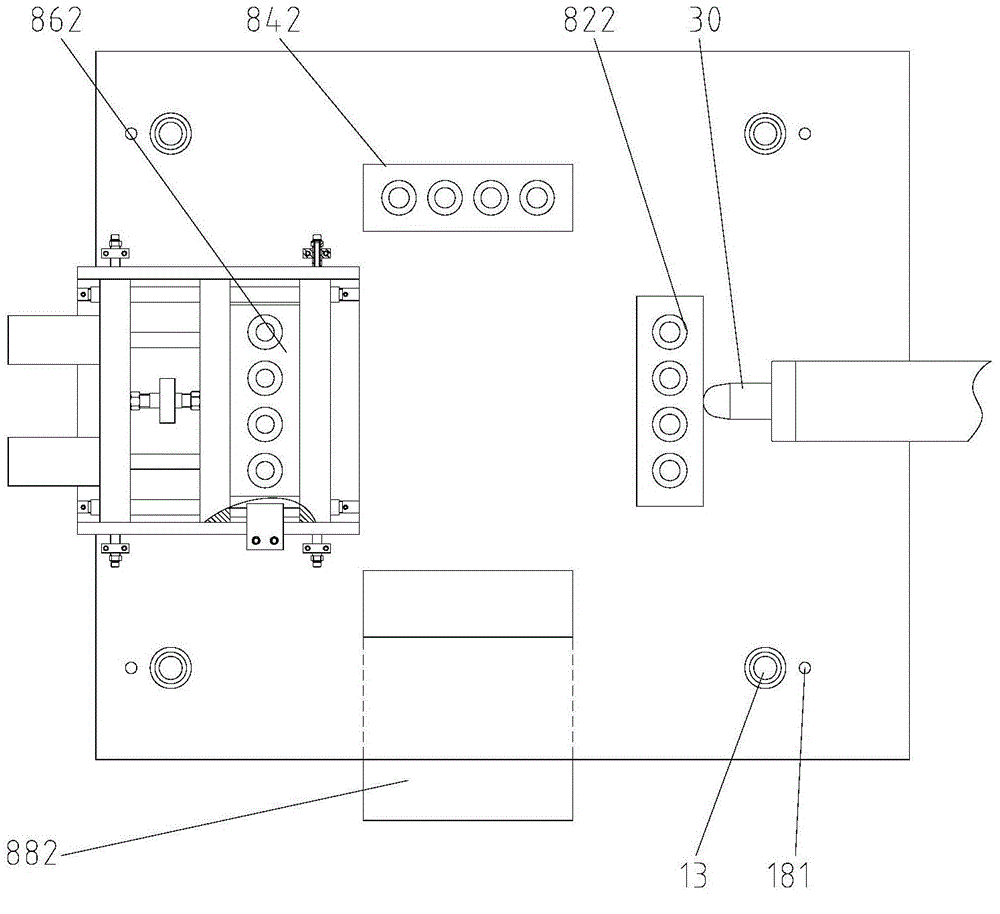

[0026] figure 1 It is a schematic diagram of the overall structure of the present invention; figure 2 for figure 1 A-direction view; image 3 for figure 1 top view. Such as figure 1 , figure 2 and combine image 3 As shown, the present invention provides a multi-station rotary molding machine, which includes a main machine and different working modules arranged on the main machine. Described main engine comprises frame 60, and workbench panel 18 is horizontally fixed on the frame 60, and workbench panel 18 is connected with lower formwork 19 through clamping oil cylinder 12, and lower formwork 19 passes through the guide column of workbench panel 18 vertically. 13 is connected with the upper template 11, and the upper template 11 is provided with a push-down oil cylinder 17. Figure 4 It is a schematic diagram of the local structure of the push-down oil cylinder, the upper template and the rotating disk of the present invention. Such as Figure 4 As shown, the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com