Method for synthesizing 3-amino-4-methoxy acetanilide by binary alloy catalysis

A technology of methoxyacetanilide and binary alloys, which is applied in chemical instruments and methods, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor stability and easy agglomeration of nano-metal catalysts , low catalytic activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Catalyst preparation:

[0029] In the presence of organic modifier CTAB, copper nitrate trihydrate, silver nitrate and hydrazine hydrate were used as raw materials to prepare nano-copper / silver binary alloy catalysts by wet chemical reduction method.

[0030] Dissolve 1.93g of copper nitrate trihydrate and 0.193g of CTAB in 40ml of absolute ethanol, and ultrasonically dissolve them for 30 minutes to form a mixed solution. When the temperature of the mixed solution rises to 60°C, add 1.5mol / L NaOH ethanol solution drop by drop to adjust The pH value of the mixed solution was 8; then dropwise added a dilute ethanol solution of hydrazine hydrate (6ml 85% hydrazine hydrate / 50ml absolute ethanol), and reacted for 2h under magnetic stirring, and cooled the prepared nano-copper to 30 ℃; Weigh 0.27g of silver nitrate and dissolve it in 20ml of absolute ethanol, add the ethanol solution of silver nitrate dropwise to the cooled mixture and react for 1 hour to prepare nano-copper-...

Embodiment 2

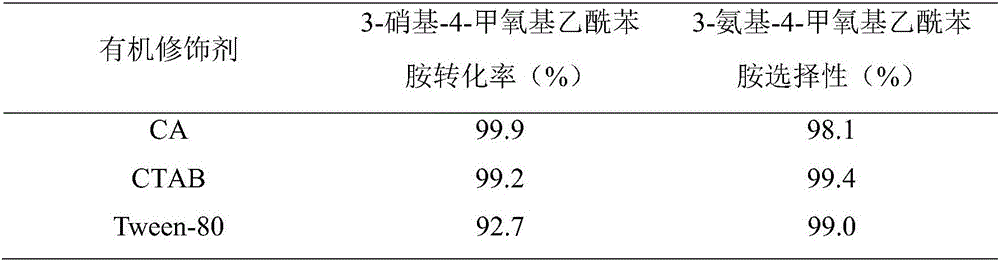

[0034] Adopt the same method of embodiment 1 to prepare nano-copper / silver binary alloy catalyst, only change organic modifier to be respectively CA, Tween-80, the process of catalyst catalytic hydrogenation 3-nitro-4-methoxyacetanilide adopts and The same method as in Example 1 can be used to obtain the influence of different modifiers on the catalytic hydrogenation of 3-nitro-4-methoxyacetanilide by preparing nano-copper / silver binary alloy catalysts. The results are shown in Table 1.

[0035] Table 1 Effect of different modifiers on the catalytic hydrogenation of 3-nitro-4-methoxyacetanilide by nano-copper / silver binary alloy catalysts

[0036]

Embodiment 3

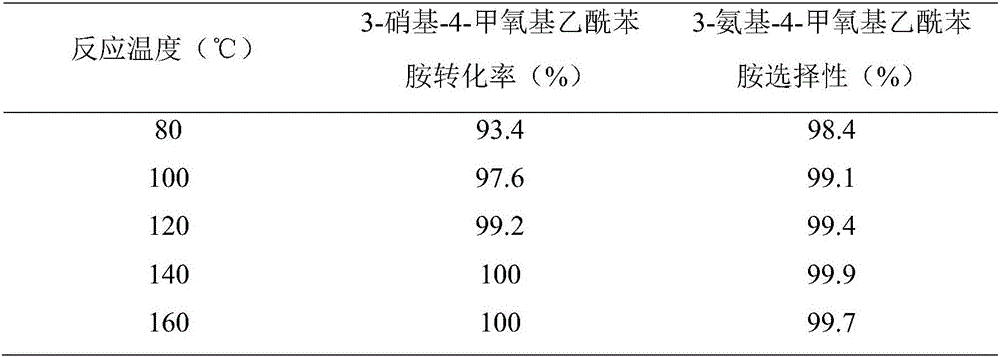

[0038] Using the same method as in Example 1 to prepare nano-Cu-Ag catalysts to catalyze the hydrogenation of 3-nitro-4-methoxyacetanilide, only changing the reaction temperature in the kettle to 80°C, 100°C, 140°C and 160°C respectively , the effect of the reaction temperature on the catalytic hydrogenation of 3-nitro-4-methoxyacetanilide can be obtained, and the results are shown in Table 2.

[0039] The influence of table 2 reaction temperature on the catalytic hydrogenation reaction of 3-nitro-4-methoxyacetanilide

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com