Dual-component silicone-acrylic anti-cracking waterproof coating and preparation method thereof

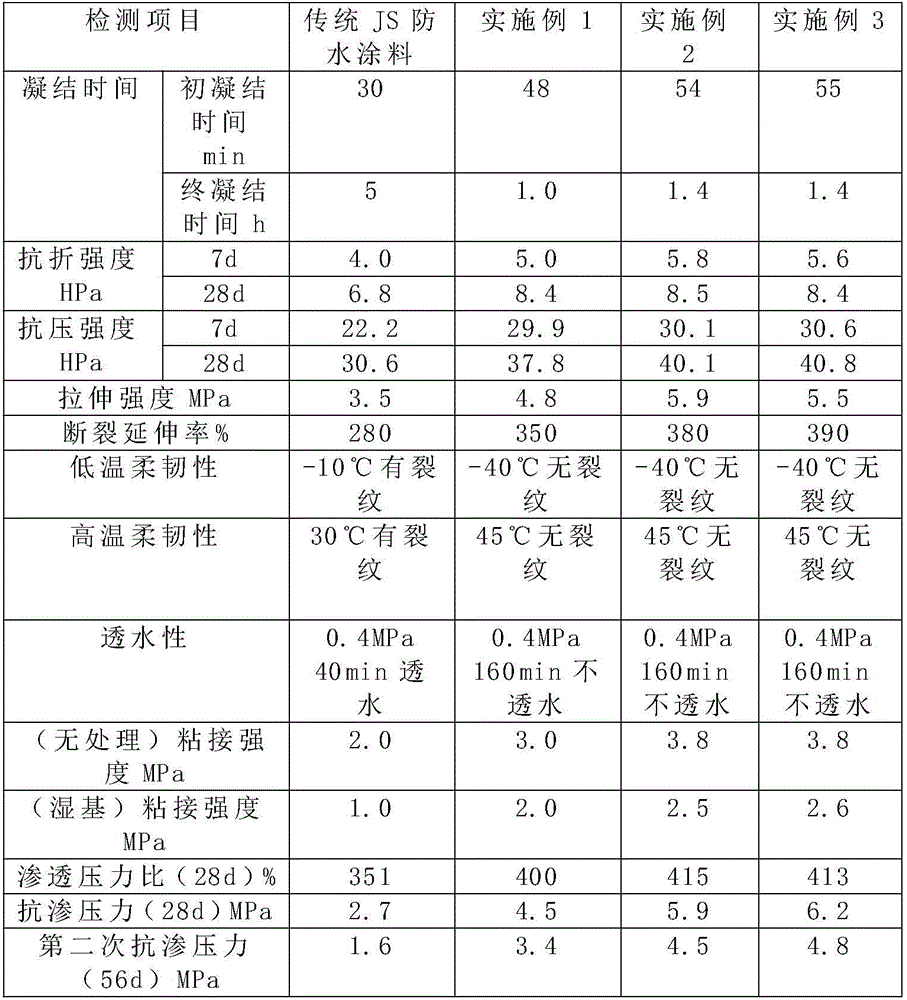

A waterproof coating, two-component technology, applied in the direction of anti-corrosion coatings, fireproof coatings, coatings, etc., can solve the problems of low tensile strength and bonding strength, low elongation at break, poor high temperature crack resistance, etc., to achieve Enhance the impermeability and waterproof performance and high temperature crack resistance, improve the impermeability and waterproof performance and high temperature crack resistance, the effect of improving tensile strength and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A two-component silicone acrylic anti-cracking waterproof coating, the waterproof coating includes a liquid material and a powder material, the mass ratio of the liquid material and the powder material is 1:2, and the liquid material includes the following components in parts by weight Parts: 85 parts of acrylic emulsion; 15 parts of silicone emulsion; 3 parts of dibutyl phthalate; 10 parts of additives; 8 parts of water; the powder includes the following components by weight: 35 parts of black cement; 45 parts of powder; 15 parts of heavy calcium powder; 10 parts of talcum powder.

[0030] The index of above-mentioned used raw material is as follows:

[0031] Acrylic emulsion: solid content: 54%~56%, viscosity: 300~1500mPa·s, pH value: 7~8, Tg value: -10℃;

[0032] Silicone emulsion: solid content: 42%-45%, viscosity: 300-1500mPa·s, pH value: 7.5-8.5, Tg value: 40°C;

[0033] Dibutyl phthalate: colorless oily liquid with a density of 1.042-1.048g / ml at 20°C.

Embodiment 2

[0035] A two-component silicone acrylic anti-cracking waterproof coating, the waterproof coating includes a liquid material and a powder material, the mass ratio of the liquid material and the powder material is 1:2, and the liquid material includes the following components in parts by weight Parts: 80 parts of acrylic emulsion; 12 parts of silicone emulsion; 2 parts of dibutyl phthalate; 4 parts of modified sodium silicate; 3 parts of propylene glycol monolaurate; 1 part of penetrant T; 2 parts of penetrant JFC 7 parts of water; the powder includes the following components by weight: 40 parts of P32.5 black cement; 42 parts of 400 mesh quartz powder; 12 parts of 400 mesh heavy calcium powder; 10 parts of 400 mesh talcum powder; modified bentonite 15 parts; 5 parts of sodium tetrapolyphosphate.

[0036] The index of above-mentioned used raw material is as follows:

[0037] Acrylic emulsion: solid content: 54%~56%, viscosity: 300~1500mPa·s, pH value: 7~8, Tg value: -10℃;

[0...

Embodiment 3

[0041] A two-component silicone acrylic anti-cracking waterproof coating, the waterproof coating includes a liquid material and a powder material, the mass ratio of the liquid material and the powder material is 1:2, and the liquid material includes the following components in parts by weight Parts: 74 parts of acrylic emulsion; 15 parts of silicone emulsion; 1.5 parts of dibutyl phthalate; 6 parts of modified sodium silicate; 3 parts of propylene glycol monolaurate; 3 parts of penetrant T; 2 parts of penetrant JFC; 5 parts of water; the powder includes the following components by weight: 35 parts of P32.5 black cement; 35 parts of 400 mesh quartz powder; 15 parts of 400 mesh heavy calcium powder; 10 parts of 400 mesh talcum powder; 10 parts of modified bentonite parts; 3 parts of sodium tetrapolyphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com