Steel structure fireproof protection plate containing silicon dioxide aerogel

A technology of silica and protective board, applied in the field of composite adhesives, can solve the problems of strength, thermal insulation performance gap, increase the density of fireproof board, poor thermal insulation performance and other problems, so as to improve thermal insulation performance and improve thermal insulation performance. , The effect of improving waterproof and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of modified water glass

[0032] (1) Preparation of preliminary modified water glass A:

[0033] The water glass, acid and organosilane were stirred and blended under the condition of pH 5 according to the mass ratio: 100:4:6, the stirring speed was 800r / min, and the time was 6 hours, wherein the organosilane was vinyltrimethyl. Oxysilane, the acid is a mixed acid of acrylic acid and phosphoric acid, and the molar ratio of the two acids is 5:5. Among them, micron-sized silica aerogel is added while stirring. Based on 100 parts by mass of water glass, micron-sized two The addition amount of the silica aerogel is 10 parts by weight, and the D50 diameter of the silica aerogel is about 100 μm.

[0034] (2) Preparation of silicone modified urethane acrylate:

[0035] In the presence of catalyst, solvent and polymerization inhibitor, isophorone diisocyanate (IPDI) trimer, γ-glycidyl ether oxypropyl trimethoxysilane and hydroxyethyl methacrylate are rea...

Embodiment 2

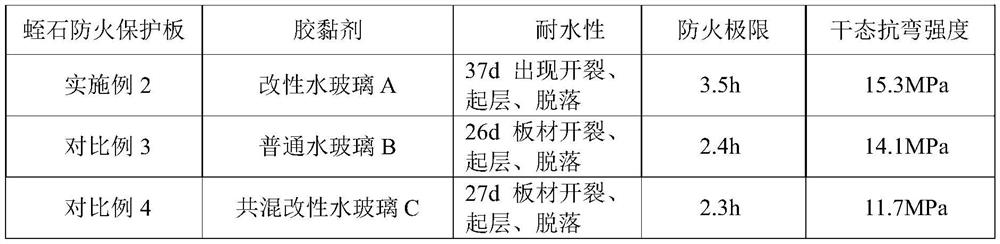

[0038] Embodiment 2 Utilize modified water glass to prepare steel structure fire protection board

[0039] The raw material formula for fire protection is: water glass 20%, expanded vermiculite 60%, kaolin 5%, perlite 5%, aluminum hydroxide 5%, reinforcing fiber 4%, sodium fluorosilicate early strength agent 1% , wherein the water glass is the modified water glass prepared in Example 1.

[0040] The specific preparation method of the vermiculite fire protection board is as follows:

[0041] (1) mixing: the raw materials are measured, and the above-mentioned raw materials are uniformly mixed in a high-speed mixer to obtain a slurry;

[0042] (2) Press molding: the slurry obtained in step (1) is pressed and molded by a mold to obtain a slab;

[0043] (3) Microwave drying and shaping: microwave drying and shaping in a microwave kiln, the drying time is 25 minutes, and finally a fireproof board with a thickness of 25mm is obtained, and the general size is 1.2m*2.4m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com