Temperature control coating with high heat conduction property and preparation method thereof

A technology of thermal conductivity and coating, applied in the field of thermal control methods to enhance thermal conductivity, can solve the problems of lack of thermal conductivity materials and low thermal conductivity, and achieve the effect of reducing system weight, high operability, and convenient maintenance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

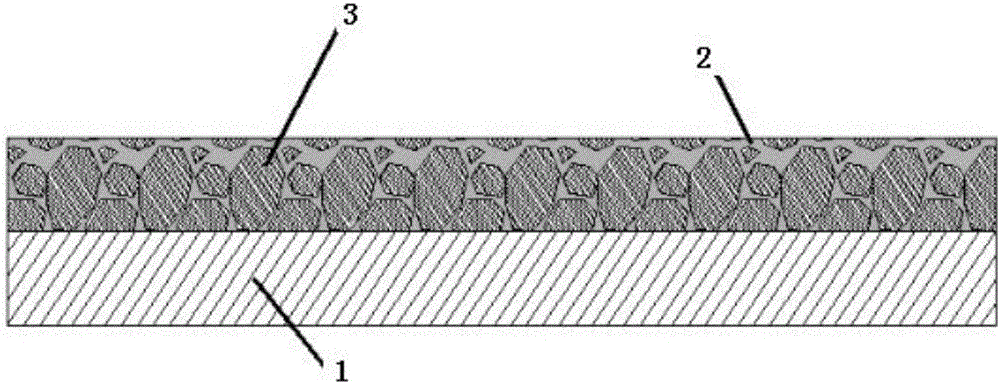

Image

Examples

Embodiment 1

[0033] This embodiment relates to a method for preparing a temperature-controlled coating with strong thermal conductivity, comprising the following steps:

[0034] (1) Preparation of paint coating Raw material preparation: raw materials include 107 room temperature vulcanized silicone rubber, thermally conductive filler particles, KH550 surface treatment agent, and xylene (thinner) as an auxiliary material.

[0035] (2) The composition of typical thermally conductive filler particles is as follows:

[0036] 1) Conductive heat-conducting filler particles: based on 100 parts of 107 RTV silicone rubber, 40 parts of 1000-mesh spherical graphite and 20 parts of 80-mesh flake graphite are required.

[0037] 2) Insulating thermally conductive filler particles: based on 100 parts of 107 room temperature vulcanized silicone rubber, 60 parts of cubic boron nitride of 500 mesh or more are required.

[0038] (3) Typical coating preparation steps are as follows:

[0039] 1) In a 1000ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com