Antistatic heat-conducting organosilicon adhesive

An organic silica gel and antistatic technology, applied in the field of materials, can solve problems such as poor thermal conductivity, achieve the effect of improving thermal conductivity, wide industrial application prospects, and good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

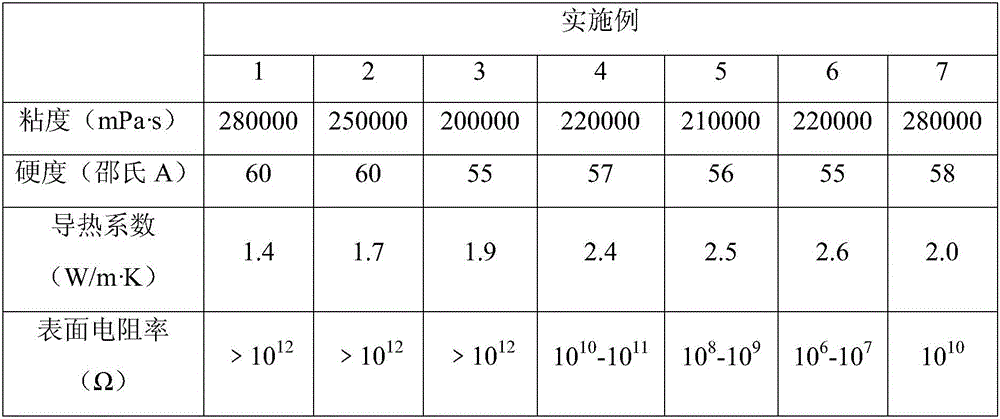

Examples

Embodiment 1

[0033] Add 100 parts of α, ω-dihydroxy polydimethylsiloxane (mass ratio: 1:1) with viscosities of 5000mPa·s and 20000mPa·s into the planetary mixer, 50 parts of nano-calcium carbonate, particle size of 40μm 600 parts of spherical alumina, after vacuuming and removing water at room temperature for 20 minutes, add 2.5 parts of cross-linking agent methyl tributylketoximosilane, 12.5 parts of vinyl tributylketoximosilane, continue to vacuumize and remove water and stir for 10 minutes Then add 3.5 parts of the adhesion promoter N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and 1 part of the catalyst dibutyltin dilaurate, and continue to stir for 10 minutes to obtain a single-component thermal conductivity Silicone adhesive.

Embodiment 2

[0035] The difference from Example 1 is that the thermally conductive filler is made by mixing 40 μm spherical alumina and 10 μm quasi-spherical alumina at a mass ratio of 4:1.

Embodiment 3

[0037] The difference from Example 1 is that the thermally conductive filler is made by mixing 40 μm spherical alumina, 10 μm spherical alumina, and 2 μm quasi-spherical alumina at a mass ratio of 2:2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com