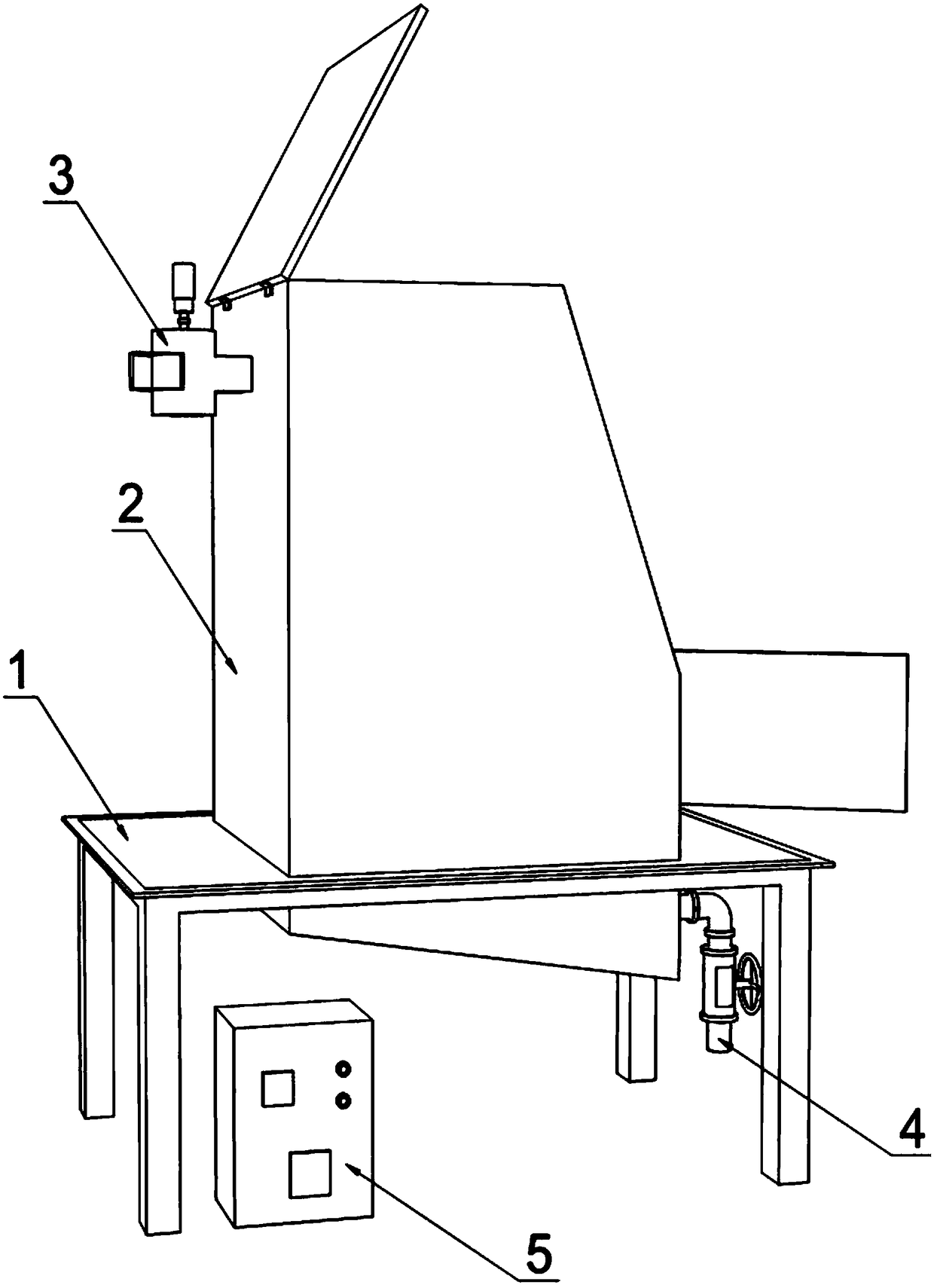

A device for harmless treatment of community domestic waste and its working method

A technology for harmless treatment and domestic waste, applied in biochemical equipment and methods, biomass post-processing, biomass pre-treatment, etc. Achieve the effect of high microbial survival rate, energy saving and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

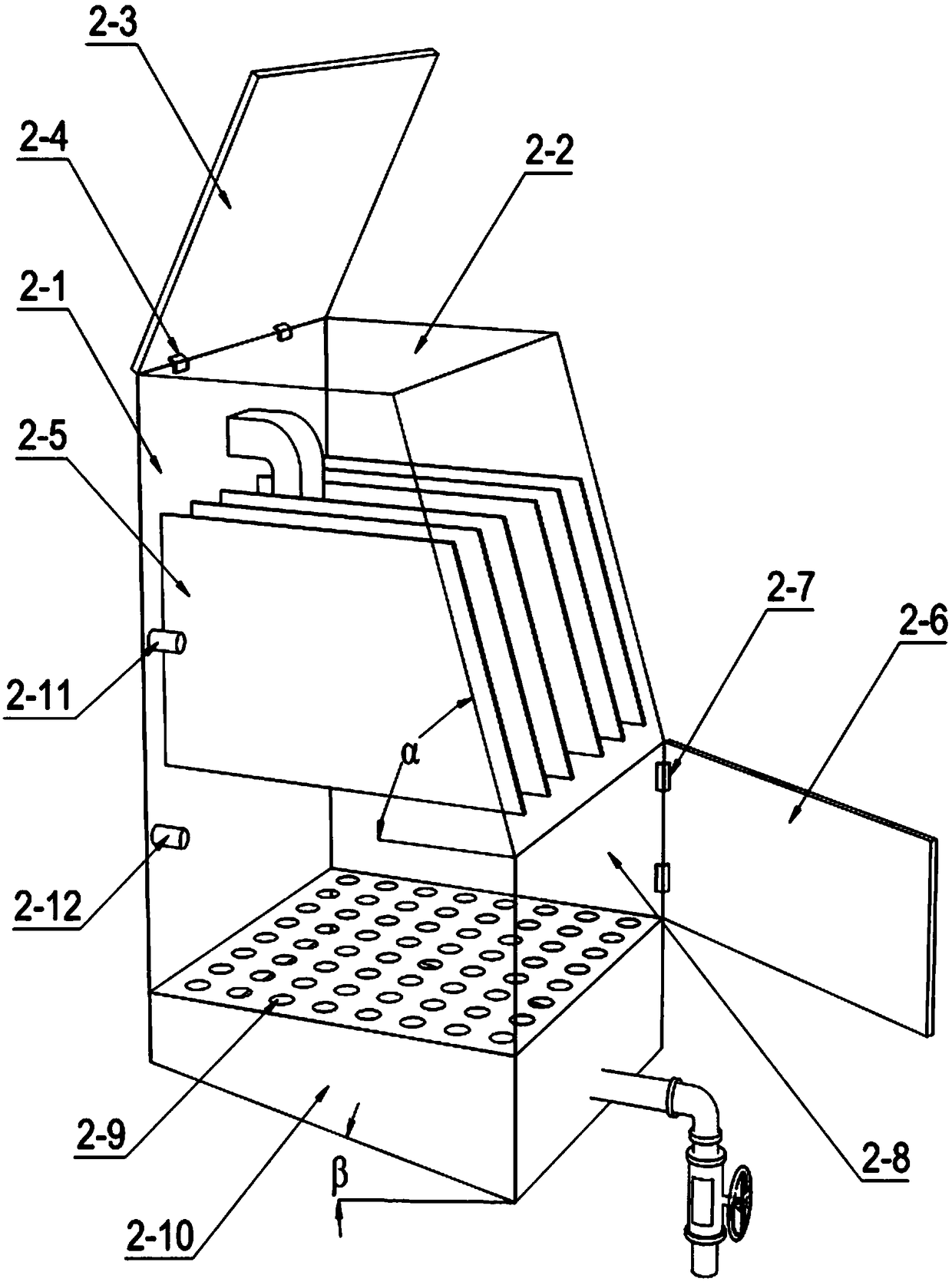

Embodiment 1

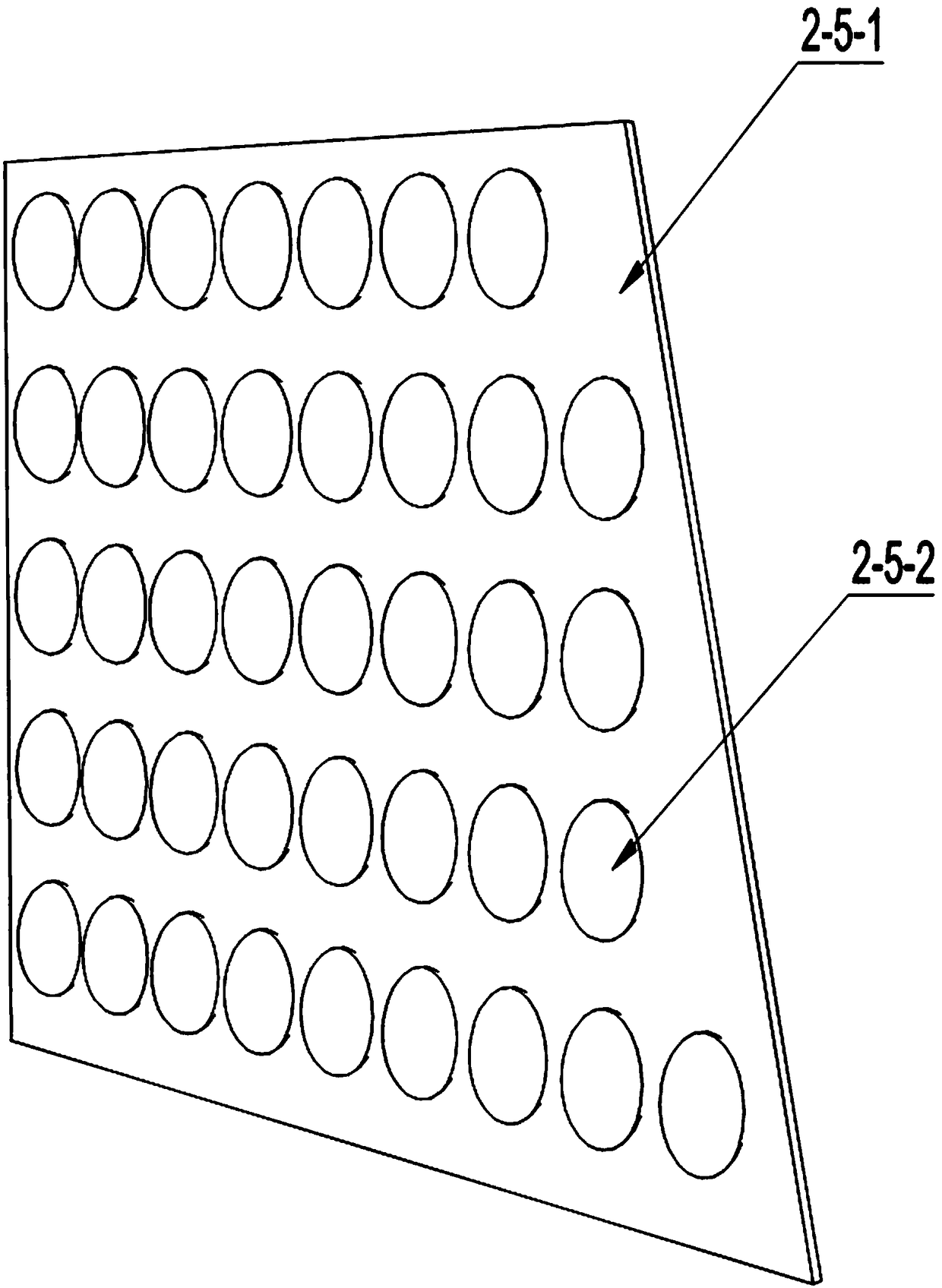

[0051] According to the following steps, the microbial growth plate 2-5 of the present invention is manufactured, and by weight fraction:

[0052] Step 1: Add 327 parts of ultrapure water with a conductivity of 1.7μS / cm into the reaction kettle, start the stirrer in the reaction kettle at a speed of 107rpm, start the heating pump, and raise the temperature in the reaction kettle to 37°C; add in order 75 parts of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polyethylene oxide ether, 47 parts of 1,3-diacetoxy-2-(diacetoxymethoxy)propane, 67 parts of 2-ethyl-2[[(decanoyl)oxy]methyl]-1,3-propanediyl dodecanoic acid diester, stir until completely dissolved, adjust the pH value to 3.7, adjust the speed of the agitator to To 137rpm, the temperature is 77°C, and the esterification reaction is 17 hours;

[0053] Step 2: Take 77 parts of oxiranyl methyl neodecanoate and 107 parts of (S)-2-(α-hydroxy-α-benzobenzyl)pyrrolemethyl ferrocene and grind them into powder particles The diameter i...

Embodiment 2

[0058] According to the following steps, the microbial growth plate 2-5 of the present invention is manufactured, and by weight fraction:

[0059] Step 1: Add 857 parts of ultrapure water with a conductivity of 2.7μS / cm into the reactor, start the stirrer in the reactor at a speed of 187rpm, start the heating pump, and raise the temperature in the reactor to 57°C; add in sequence 165 parts of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polyethylene oxide ether, 97 parts of 1,3-diacetoxy-2-(diacetoxymethoxy)propane, 107 parts of 2-ethyl-2[[(decanoyl)oxy]methyl]-1,3-propanediyl dodecanoic acid diester, stir until completely dissolved, adjust the pH value to 8.7, adjust the speed of the agitator to To 227rpm, the temperature is 147°C, and the esterification reaction is 37 hours;

[0060] Step 2: Take 147 parts of oxiranyl methyl neodecanoate and 207 parts of (S)-2-(α-hydroxy-α-phenylbenzyl)pyrrolemethyl ferrocene and grind them into powder particles The diameter is 187 mesh; add ...

Embodiment 3

[0065] According to the following steps, the microbial growth plate 2-5 of the present invention is manufactured, and by weight fraction:

[0066] Step 1: Add 500 parts of ultrapure water with a conductivity of 2.3μS / cm into the reactor, start the stirrer in the reactor at a speed of 157rpm, start the heating pump, and raise the temperature in the reactor to 47°C; add in order 125 parts of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polyethylene oxide ether, 67 parts of 1,3-diacetoxy-2-(diacetoxymethoxy)propane, 87 parts of 2-ethyl-2[[(decanoyl)oxy]methyl]-1,3-propanediyl dodecanoic acid diester, stir until completely dissolved, adjust the pH value to 5.7, adjust the speed of the agitator to To 187rpm, the temperature is 117°C, and the esterification reaction is 27 hours;

[0067] Step 2: Take 117 parts of oxiranyl methyl neodecanoate and 177 parts of (S)-2-(α-hydroxy-α-phenylbenzyl)pyrrolemethyl ferrocene and grind them into powder particles The diameter is 147 mesh; add 97 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com