Multifunctional color yarn, multifunctional knitted fabric and preparation method

A knitted fabric, multi-functional technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of difficult to reproduce color, poor wearability of fabrics, shrinkage and stability, dimming of color and light, etc. Good stability, green and environmental protection functionality, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

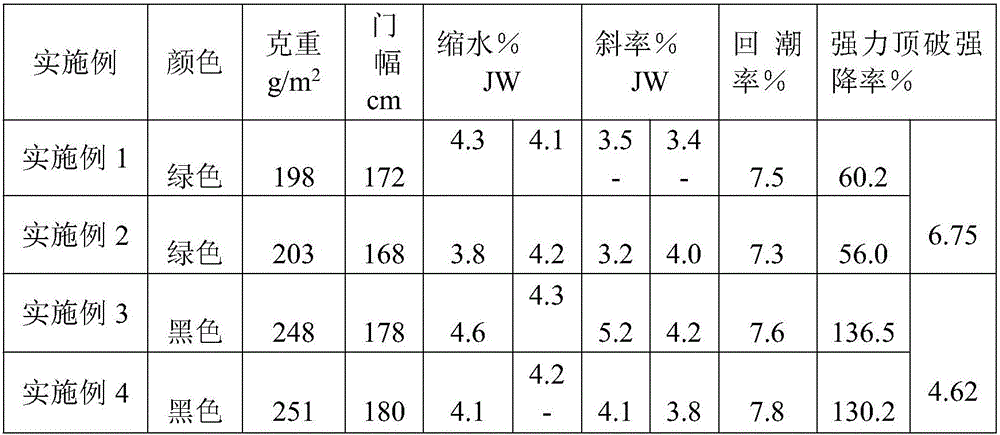

[0034] The preparation of embodiment 1 multifunctional knitted fabric specifically comprises the following steps:

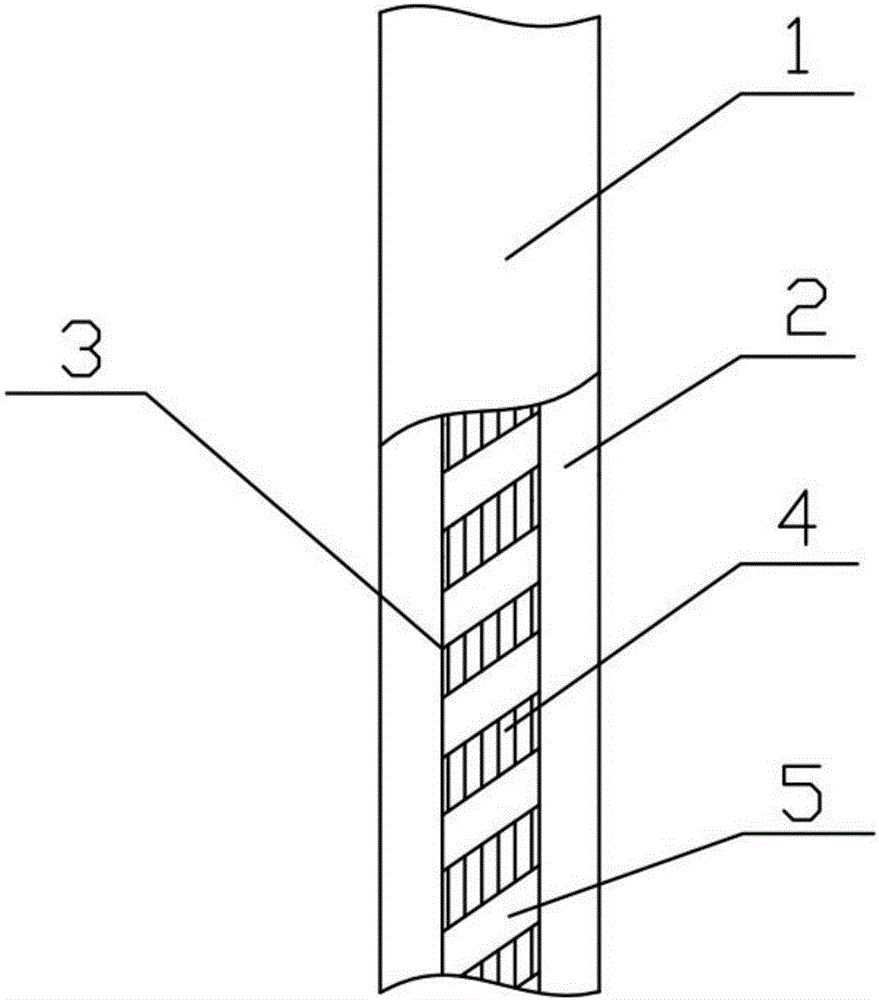

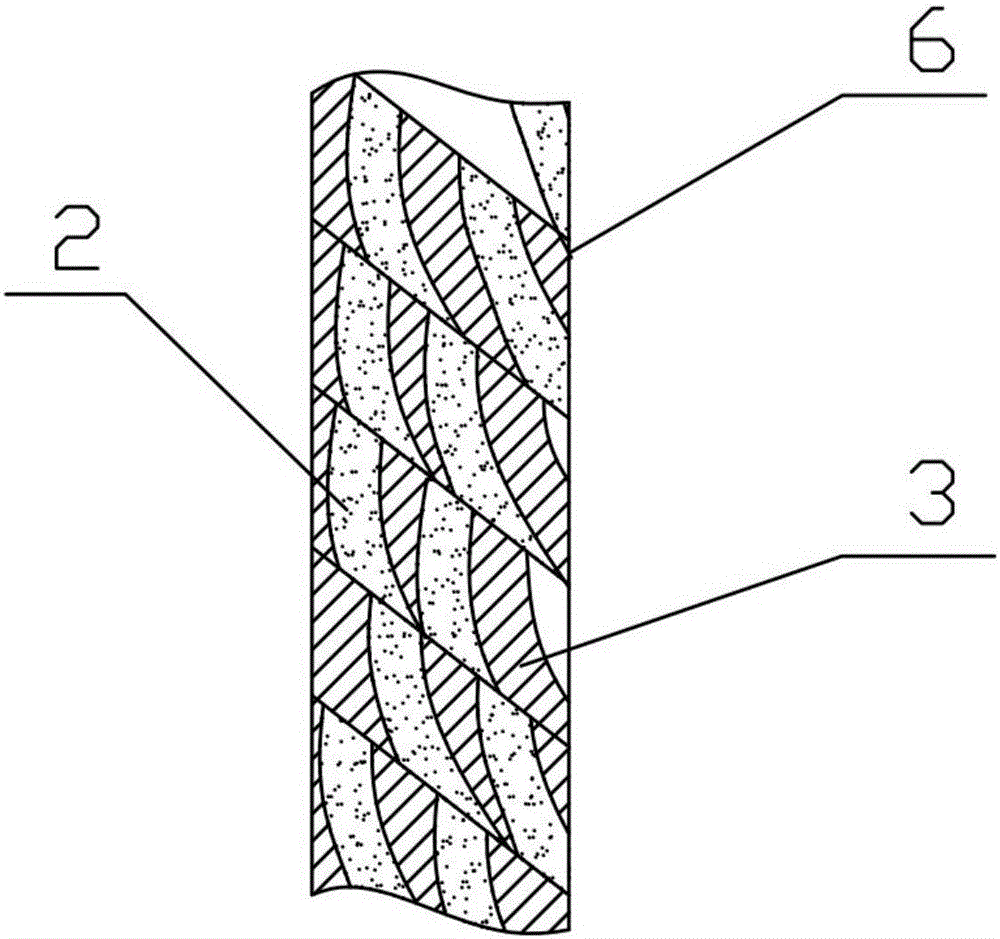

[0035] (1) Multi-functional colored yarns or multi-functional composite colored yarns are used to knit knitted gray fabrics, wherein the colored yarns are 2 S-twisted side-by-side composite yarns, and the colored yarns contain 30% colored viscose fibers and Tencel Fiber 30% and FDY PTT polyester yarn 40%, the twist of ring spinning yarn 3 is 400T / M;

[0036](2) Refining the knitted gray fabric in turn—washing—HAC neutralization—adding a compound finishing agent (4-8g / l) into the cylinder—dehydration—padding again compounded multifunctional finishing agent ( 8~12g / l)——stenter setting—(sanding, brushing)——cloth inspection—rolling and packaging, that is, multi-functional colored yarn knitted fabrics.

[0037] Among them, the component distribution ratio of the finishing agent is: 20 parts of nano-kaolin clay, 10 parts of dispersant, 40 parts of GP-105 piperidinylpr...

Embodiment 2

[0039] The preparation of embodiment 2 multifunctional knitted fabrics specifically comprises the following steps:

[0040] (1) Multi-functional colored yarns or multi-functional composite colored yarns are used to knit knitted fabrics, wherein the colored yarns are a plurality of Z-twist side-by-side composite yarns, and the colored yarns contain 30% colored viscose fibers and tencel Fiber 30% and FDY PTT polyester yarn 40%, the twist of ring spinning yarn 3 is 400T / M;

[0041] (2) Refining the knitted gray fabric in turn—washing—HAC neutralization—adding a compound finishing agent (4-8g / l) into the cylinder—dehydration—padding again compounded multifunctional finishing agent ( 8~12g / l)——stenter setting—(sanding, brushing)——cloth inspection—rolling and packaging, that is, multi-functional colored yarn knitted fabrics.

[0042] The difference from the above Example 1 is that the component distribution ratio of the finishing agent is: 14 parts of nano-kaolin clay, 9 parts of d...

Embodiment 3

[0043] The preparation of embodiment 3 multifunctional knitted fabrics specifically comprises the following steps:

[0044] (1) Multi-functional colored yarns or multi-functional composite colored yarns are used to knit knitted fabrics, wherein the colored yarns are a plurality of Z-twist side-by-side composite yarns, and the colored yarns contain 35% of colored viscose fibers and Tencel 25% fiber and 40% PTT polyester yarn of FDY, the twist of ring spinning yarn 3 is 500T / M;

[0045] (2) Refining the knitted gray fabric in turn—washing—HAC neutralization—adding a compound finishing agent (4-8g / l) into the cylinder—dehydration—padding again compounded multifunctional finishing agent ( 8~12g / l)——stenter setting—(sanding, brushing)——cloth inspection—rolling and packaging, that is, multi-functional colored yarn knitted fabrics.

[0046] Among them, the component distribution ratio of the finishing agent is: 12 parts of nano-kaolin clay, 8 parts of dispersant, 35 parts of GP-105 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com