Spinning printing and dyeing green environment-friendly edible acidic body and preparation method thereof

A green, environmentally friendly, textile printing and dyeing technology, applied in the field of textile printing and dyeing, can solve problems such as insecurity, burns, permanent disability, etc., and achieve the effect of preventing residual color pollution and impurities, preventing secondary pollution, and strong decontamination ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

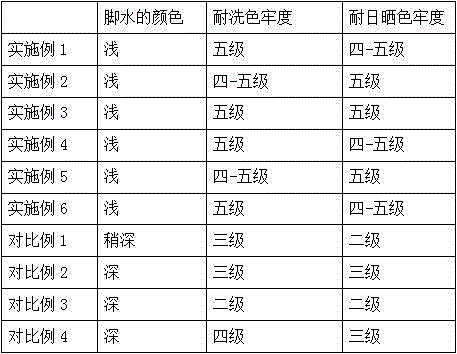

Examples

Embodiment 1

[0026] Deionized water 26kg, potassium hydrogen persulfate 4.6kg, white vinegar 10kg and citric acid 56kg.

[0027] Add deionized water into the reaction kettle, start stirring and heat up to 46°C; add potassium hydrogen persulfate, stir and keep warm for 26 minutes, then continue to heat up to 100°C; stir and keep warm for 28 minutes, then cool down to 46°C; add white vinegar, stir After 6 minutes, slowly add citric acid; after adding citric acid, close the reaction kettle, stir and keep warm for 48 minutes; the acidic body can be obtained. The obtained acidic body will not crystallize even if it is left for 96 days when it is exposed to the air at normal temperature.

Embodiment 2

[0029] Deionized water 26kg, potassium hydrogen persulfate 6.8kg, white vinegar 16kg and citric acid 68kg.

[0030] Add deionized water into the reaction kettle, start stirring and heat up to 46°C; add potassium hydrogen persulfate, stir and keep warm for 26 minutes, then continue to heat up to 100°C; stir and keep warm for 28 minutes, then cool down to 46°C; add white vinegar, stir After 6 minutes, slowly add citric acid; after adding citric acid, close the reaction kettle, stir and keep warm for 48 minutes; the acidic body can be obtained. The obtained acidic body will not crystallize even if it is left for 96 days when it is exposed to the air at normal temperature.

Embodiment 3

[0032] 26kg of deionized water, 4.6kg of potassium hydrogen persulfate, 16kg of white vinegar and 60kg of citric acid.

[0033] Add deionized water into the reaction kettle, start stirring and heat up to 46°C; add potassium hydrogen persulfate, stir and keep warm for 26 minutes, then continue to heat up to 100°C; stir and keep warm for 28 minutes, then cool down to 46°C; add white vinegar, stir After 6 minutes, slowly add citric acid; after adding citric acid, close the reaction kettle, stir and keep warm for 48 minutes; the acidic body can be obtained. The obtained acidic body will not crystallize even if it is left for 96 days when it is exposed to the air at normal temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com