A method for surface precipitation and crystallization type coating modification of fly ash used as papermaking filler

A technology of precipitation crystallization and paper-making filler, which is applied in the direction of adding inorganic compounds, can solve the problems of application limitations, difficulty in meeting high-whiteness paper filling, etc., and achieve the effects of convenient acquisition, low cost, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

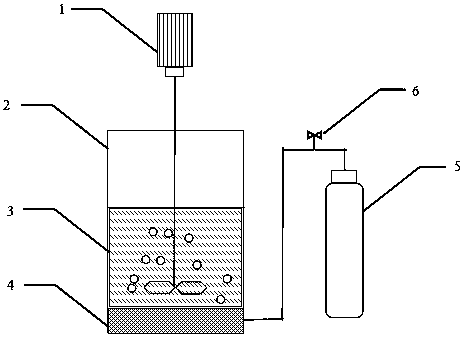

Method used

Image

Examples

Embodiment 1

[0030] at 25 o C condition according to M 粉煤灰 :M 氢氧化钙(溶质) =1.0 mass ratio equipped with fly ash (average particle size 40μm) and Ca(OH) 2 Mix the suspension, and adjust the mass concentration of fly ash in the mixture to 30%. Then, CO was introduced at a flow rate of 0.4 L / min at a stirring rate of 400 rpm. 2 Gas, after 50min, stop feeding CO 2 Gas and agitation terminate the reaction, take a sample to measure the whiteness of 73%ISO, dilute it with water to a concentration of 1% by mass, and then use it for papermaking and filling.

Embodiment 2

[0032] at 25 o C condition according to M 粉煤灰 :M 氢氧化钙(溶质) =1.6 mass ratio equipped with fly ash (average particle size around 40μm) and Ca(OH) 2 Mix the suspension, and adjust the mass concentration of fly ash in the mixture to 40%. Then, CO was introduced at a flow rate of 0.1 L / min at a stirring rate of 400 rpm. 2 Gas, after 30min, stop feeding CO 2 Gas and agitation terminate the reaction, take a sample to measure the whiteness of 78% ISO, and dilute it with water to a concentration of 5% by mass for papermaking and filling.

Embodiment 3

[0034] at 25 o C condition according to M 粉煤灰 :M 氢氧化钙(溶质) =0.185 mass ratio equipped with fly ash (average particle size around 40μm) and Ca(OH) 2 Mix the suspension, and adjust the mass concentration of fly ash in the mixture to 25%. Then, CO was introduced at a flow rate of 0.1 L / min at a stirring rate of 300 rpm. 2 Gas, after 30min, stop feeding CO 2 Gas and agitation terminate the reaction, and the whiteness is measured as 86%ISO by sampling. It is diluted with water to a concentration of 10% by mass and then used for filling in papermaking.

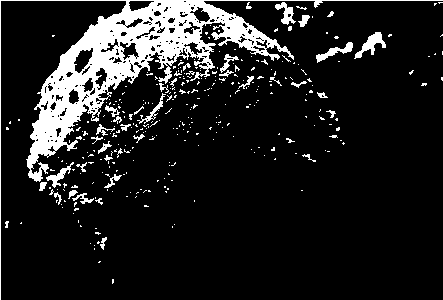

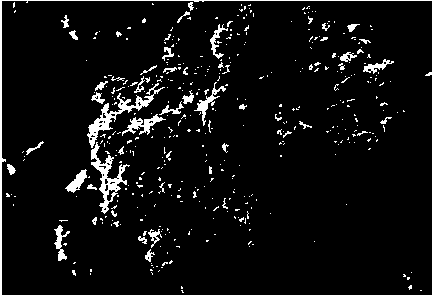

[0035] Such as figure 2 Shown is the SEM morphology of fly ash particles before surface modification, image 3 It is the SEM morphology of fly ash particles after surface modification. It can be clearly seen that a large number of calcium carbonate crystals with a particle size much smaller than the original coal ash particles are fixed on the surface of the fly ash particles, and they are evenly arranged, playing a certain co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com