Assembling type stair and mounting method thereof

An installation method and assembly technology, applied in the direction of stairs, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of simple construction process, shortened construction period, and good structural formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

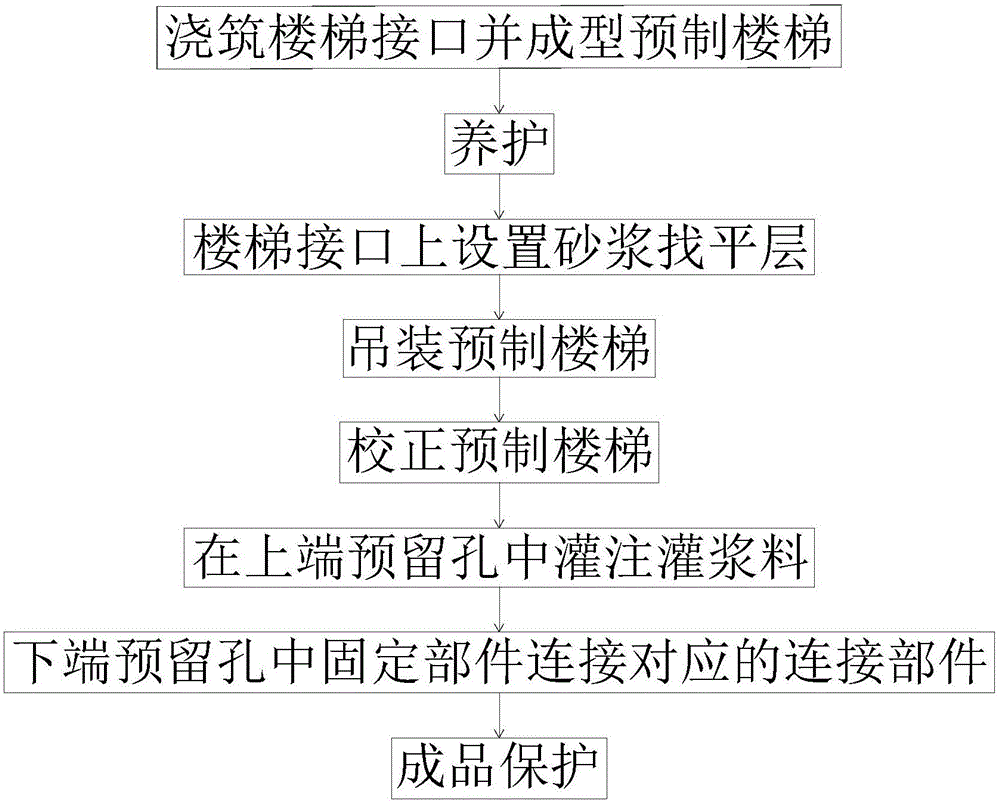

[0048] like Figure 1-4 As shown, the installation method of the prefabricated staircase of the present invention comprises the following steps:

[0049] A. The prefabricated staircase 1 is formed, and the prefabricated staircase 1 component is molded according to actual requirements, and the upper and lower ends of the prefabricated staircase 1 are respectively provided with reserved holes 11 for installation;

[0050] Build the support system 5 and the mold required for the molding of the staircase interface 2, pour and form the upper and lower two staircase interfaces 2 connected to the two ends of the prefabricated staircase 1, and pre-embed the connecting parts in each of the staircase interfaces 2;

[0051]B. Maintain the strength of all the staircase interfaces 2 to meet the design requirements;

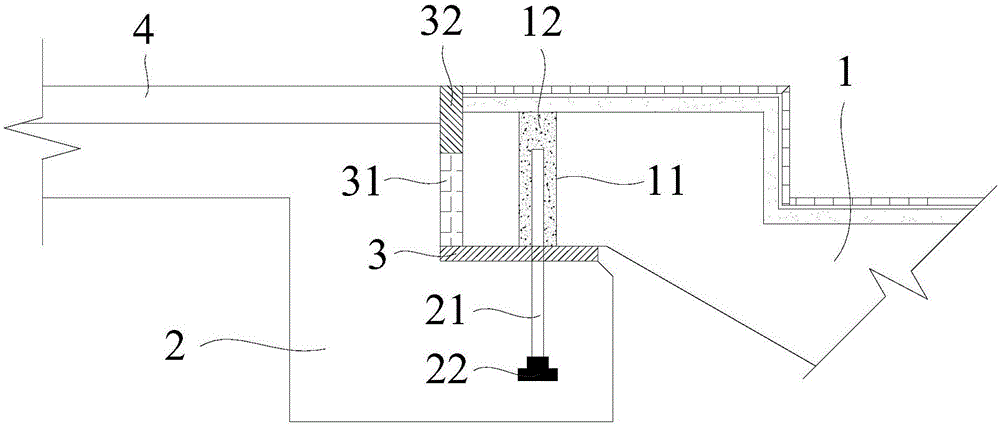

[0052] C. On each of the stair interfaces 2, a mortar leveling layer 3 is provided at the upper and lower contact surfaces of the prefabricated stairs 1;

[0053] D. Hoistin...

Embodiment 2

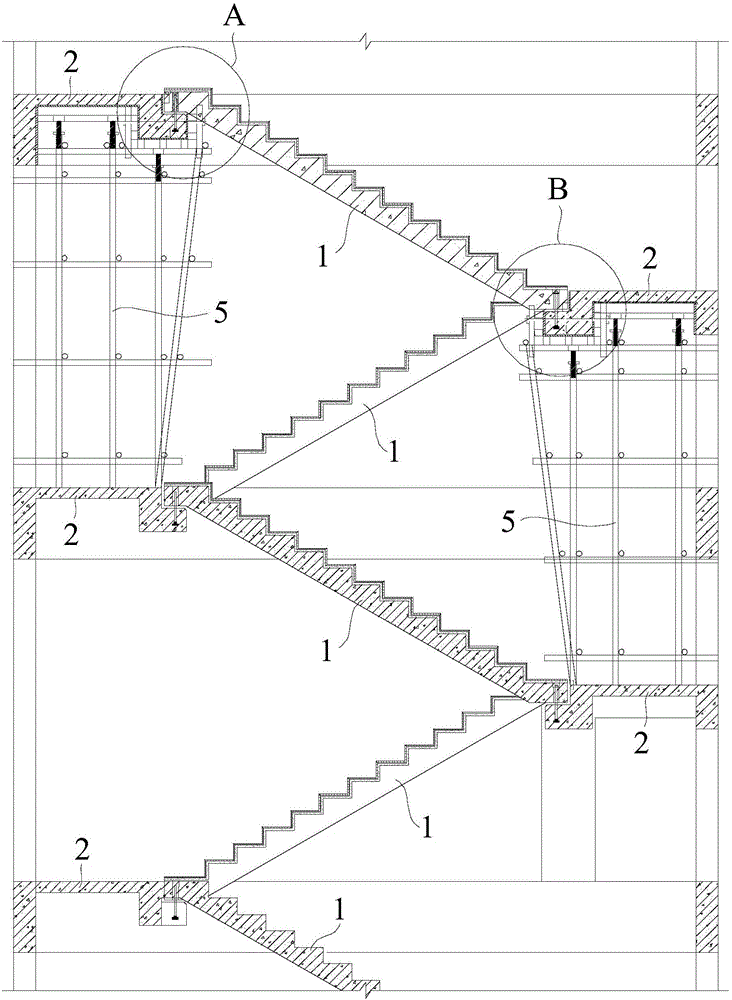

[0064] like Figure 2-4 As shown, the prefabricated staircase of the present invention includes a prefabricated staircase 1 and two staircase interfaces 2 respectively connected to its two ends.

[0065] All the stair interfaces 2 are cast-in-situ structural parts, and the prefabricated stairs 1 are provided with fixed hinge supports, which are connected to the stair interfaces 2 at the upper end, that is, the prefabricated stairs 1 can be opposite to the stair interface 2 at the upper end. Rotation, horizontal and vertical direction can not move, the prefabricated staircase 1 is provided with a sliding support, connected to the lower end of the staircase interface 2, that is, the prefabricated staircase 1 can be rotated relative to the lower end of the staircase interface 2, the horizontal direction move, and cannot move in the vertical direction; wherein, the two stair interfaces 2 are respectively connected to the fixed hinge support at the upper end of the prefabricated st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com