Plug structure mounted between template trolley and surrounding rock, and mounting method of plug structure

A formwork trolley and surrounding rock technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as difficulty in bypassing exposed steel bars, waste of wood, and low wood reuse rate, and achieve the elimination of hidden dangers of tunnel water leakage, Improving the sealing performance of mold closing, facilitating popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

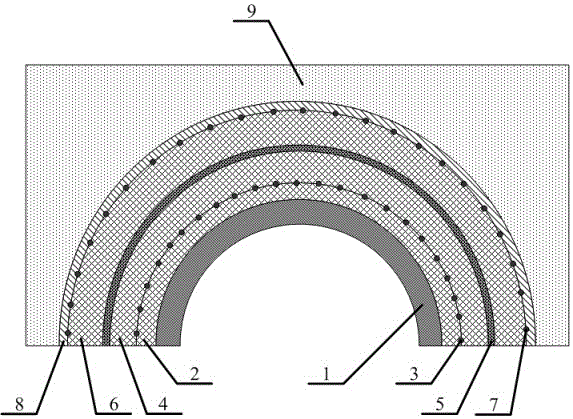

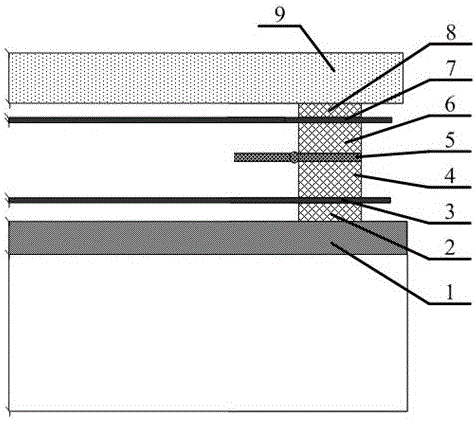

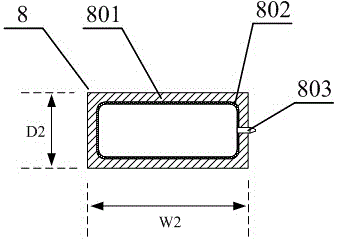

[0026] figure 1 shows a cross-sectional schematic view of the plug structure provided by the present invention, figure 2 A schematic view of the longitudinal section structure of the plug structure provided by the present invention is shown, image 3 It shows a cross-sectional schematic diagram of the inflatable layer in the plug structure provided by the present invention, Figure 4 It shows a schematic view of the longitudinal section structure of the inflatable layer in the plug structure provided by the present invention, Figure 5 A schematic diagram of the three-dimensional structure of the foamed rubber brick in the plug structure provided by the present invention is shown.

[0027] The plug structure installed between the formwork trolley and the surrounding rock provided in this embodiment means that the first elastic material layer 2 and the inner ring steel bar 3 are successively laid circumferentially at the end of the formwork trolley towards the surrounding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com