A kind of evaporator of loop heat pipe and its preparation method

A loop heat pipe and evaporator technology, used in evaporators/condensers, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of low reliability, inability to start, unfavorable vapor-liquid separation, etc., and achieve easy installation. The effect of easy operation, simple structure and application, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

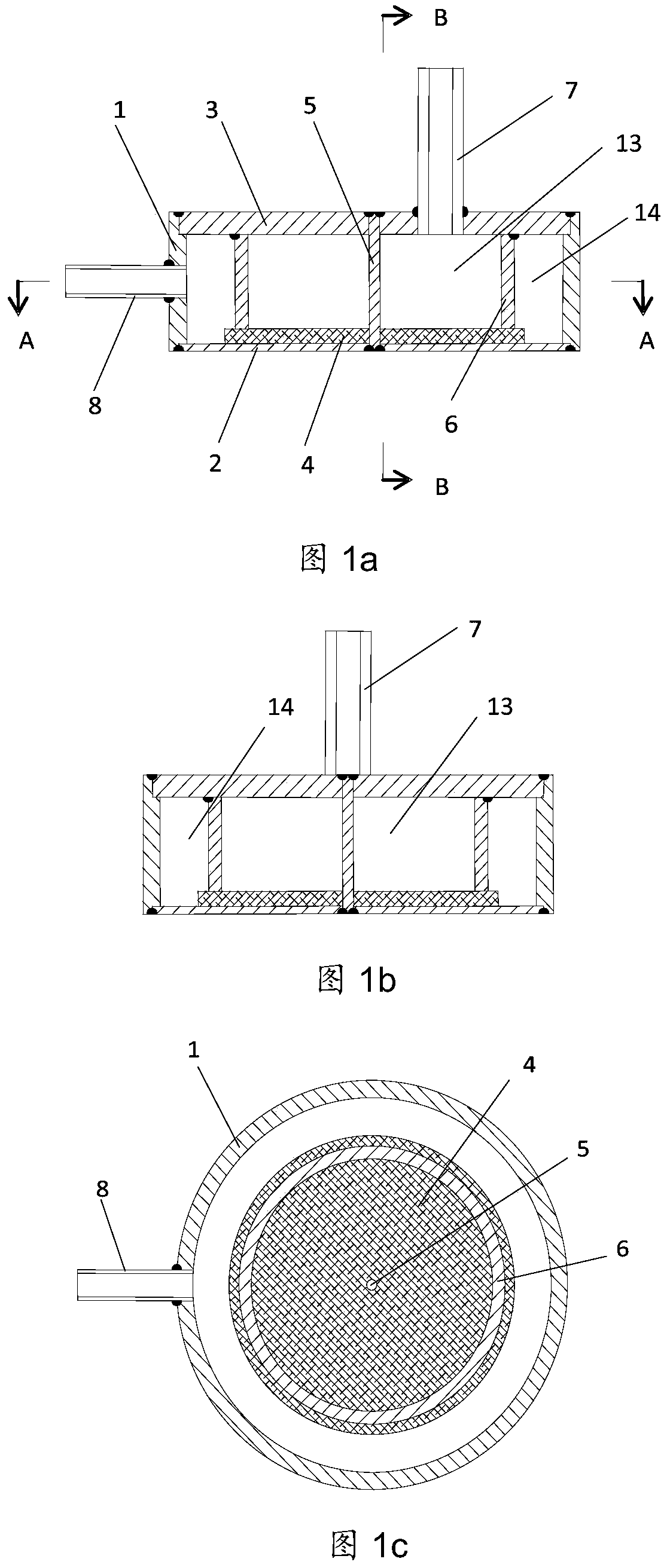

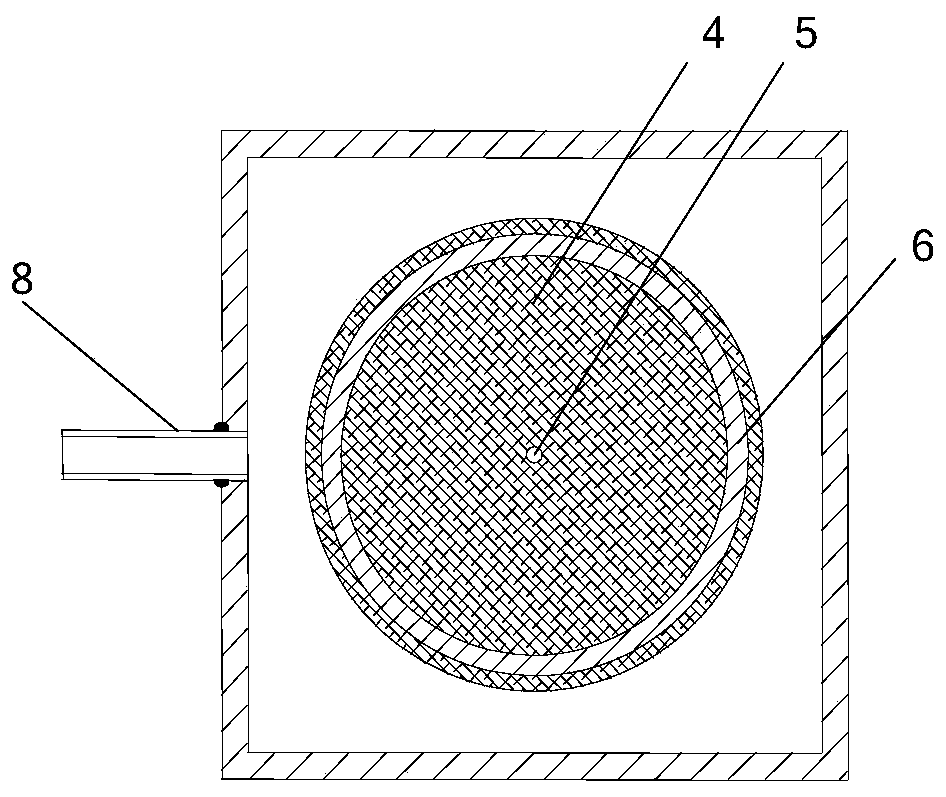

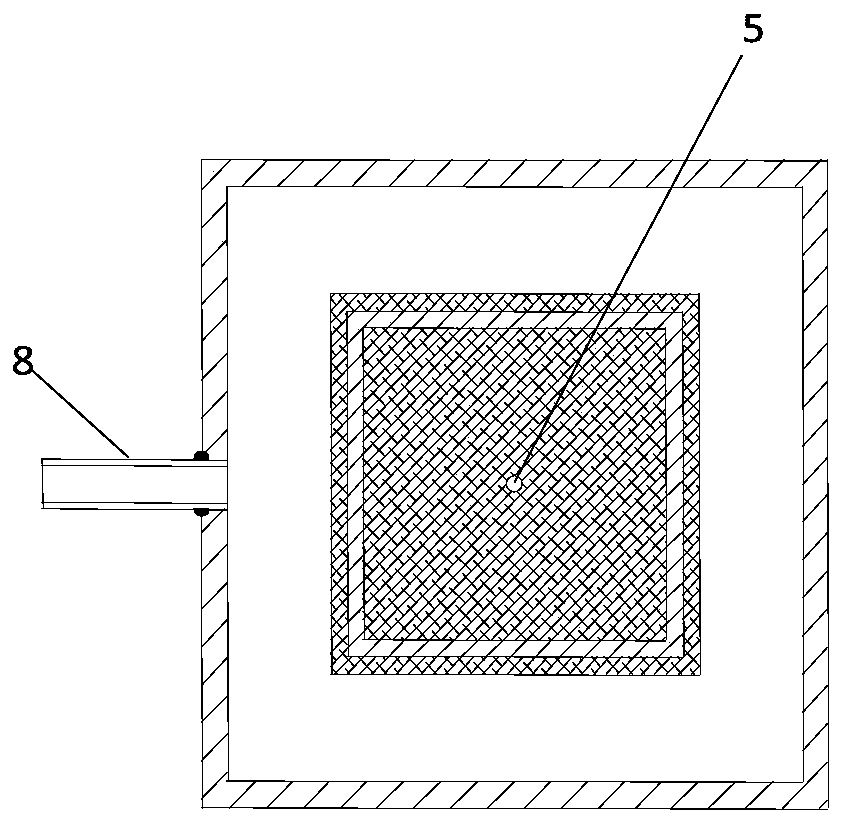

[0045] Such as figure 1 Shown are three side views of the evaporator of the loop heat pipe of the present invention, wherein figure 1 a is the main view, figure 1 b is a side view, figure 1 c is a partial top view, as can be seen from the figure, the evaporator of the loop heat pipe of the present invention includes an outer cylinder wall 1, a heat-absorbing surface 2, an upper end cover 3, a capillary core 4, a reinforcing column 5, a vapor-liquid isolation barrel 6, and a steam outflow pipe joint 7 and a liquid return pipe joint 8, wherein the vapor-liquid isolation barrel 6 is a cylindrical thin-walled structure with openings at both ends, the upper end cover 3 and the heat-absorbing surface 2 are respectively located on the upper and lower end surfaces of the outer cylinder wall 1, the outer cylinder wall 1, the heat-absorbing surface The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com