Optical fiber humidity sensor with ultrahigh sensitivity and based on all-agar F-P cavity

A humidity sensor and sensitivity technology, applied in the field of optical fiber humidity sensors, can solve the problems of information loss and weakening, and achieve the effects of short response time, reduced manufacturing cost, and easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

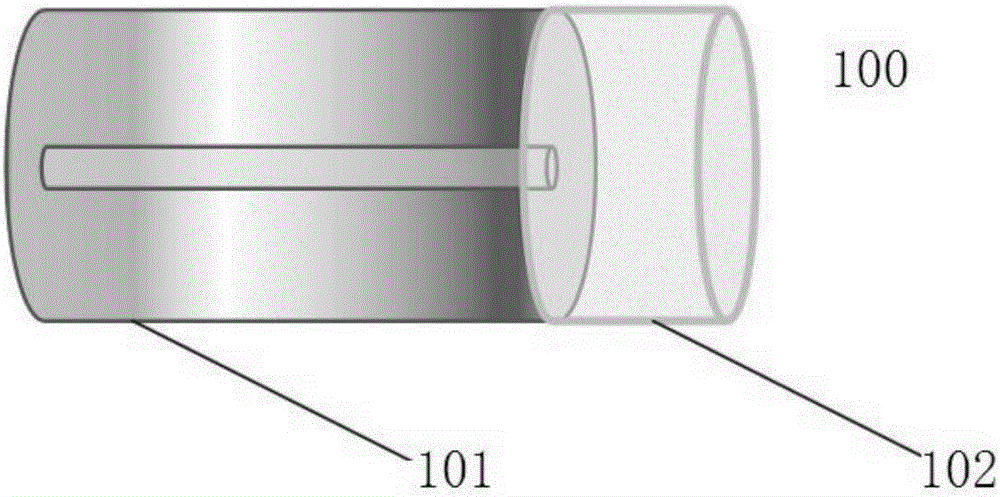

[0020] as attached figure 1 As shown, the ultra-high sensitivity optical fiber humidity sensor 100 based on the full agar F-P cavity of the present invention is composed of a single-mode optical fiber 101 and an agar F-P cavity 102. Due to the difference in refractive index, the optical fiber-agar and agar-air can be viewed as As two optical interfaces, this constitutes an F-P cavity. According to the working principle of the F-P cavity, the reflection spectrum can be modified by the refractive index (n) and the cavity length (L), which both change with the relative humidity (RH). The sensitivity of the sensor can be expressed as:

[0021] Δ λ Δ R H = λ ( 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com