Integrated small-sized laser gas detecting component

A technology for laser gas and detection components, applied in the field of detection, can solve the problems of inability to miniaturize and integrate in shape and size, unfavorable miniaturization of integrated gas detection components, complex laser gas detection systems, etc., and achieves low power consumption, Stable working temperature and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention relates to a laser gas detection component, more specifically, to an integrated small laser gas detection component, which belongs to the detection technology field.

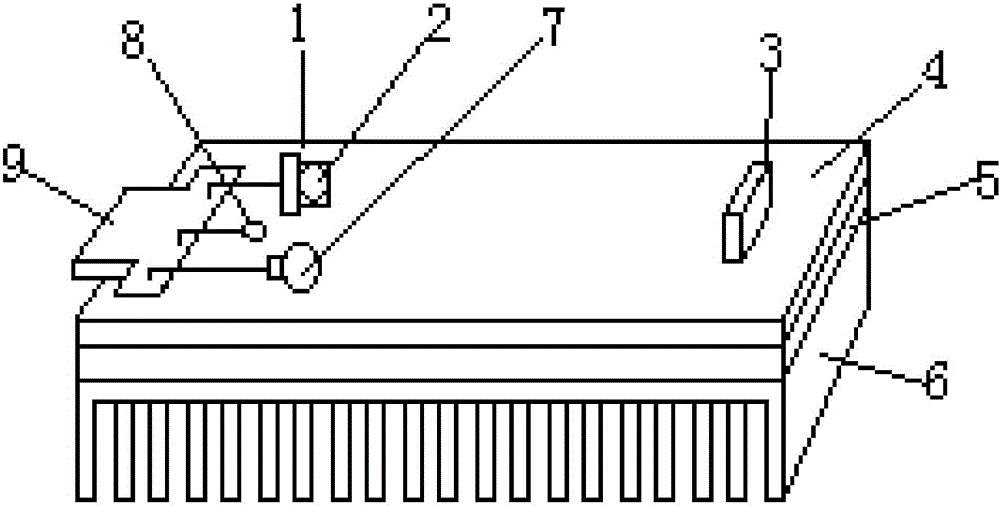

[0030] Such as figure 1 As shown, an integrated small-scale laser gas detection assembly includes a metal plate 4 sequentially connected from top to bottom, a semiconductor refrigerator 5 and a radiator 6, and a terminal 9 as an electrical connection port is fixed above the metal plate 4 , a thermistor 8, a semiconductor laser 1, a spherical quartz lens 2, a photodetector 7 and a plane reflector 3; the laser light emitted by the semiconductor laser 1 is aligned with the plane reflector 3 through the spherical quartz lens 2 and is reflected by the plane After being reflected by the mirror 3, it is received by the photodetector 7; the semiconductor laser 1, the semiconductor refrigerator 5, the photodetector 7 and the thermistor 8 are respectively connected to the terminal 9.

[0031] Wherein...

Embodiment 2

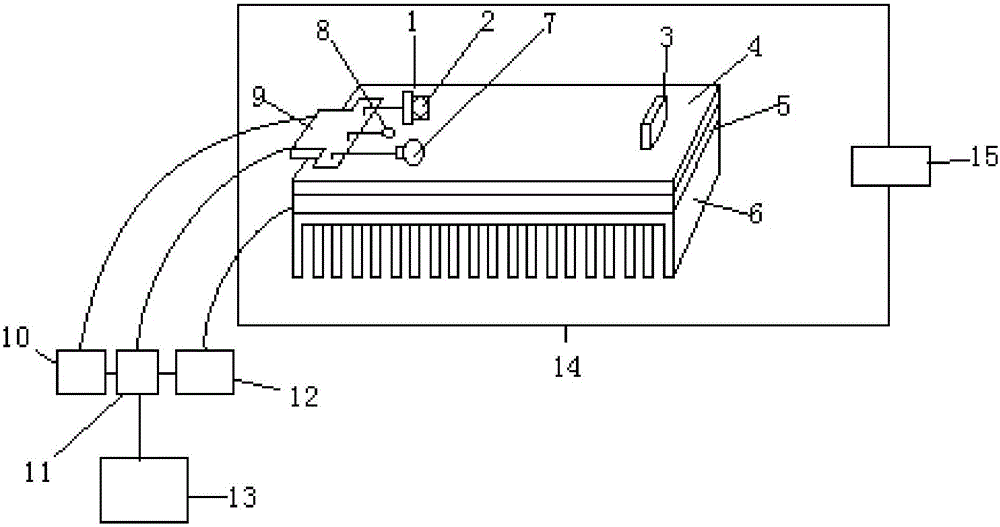

[0050] Such as figure 2 As shown, the assembly described in Embodiment 1 including parts 1-9 is placed in the closed casing 14, and the air inlet 5 is installed on the closed casing 14. Outside the closed casing 14, the single-chip microcomputer 11 is respectively connected to Analog-to-digital converter 10, relay 12, display screen 13; The connecting terminal 9 that is positioned at described closed case 14 interior connects single-chip microcomputer 11 and analog-to-digital converter 10 respectively, and described semiconductor refrigerator 5 is connected with described closed case 14 outside The relay 12 is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com