Laser beam coupling detection and debugging structure and detection and debugging method

A debugging method and a laser beam technology, applied in the application field of laser technology, can solve the problem that the coupling efficiency needs to be improved, and achieve the effects of avoiding loss, high coupling efficiency, and improving the qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It can be seen from the background art that the coupling efficiency of the laser beam coupled to the optical fiber in the prior art still needs to be improved.

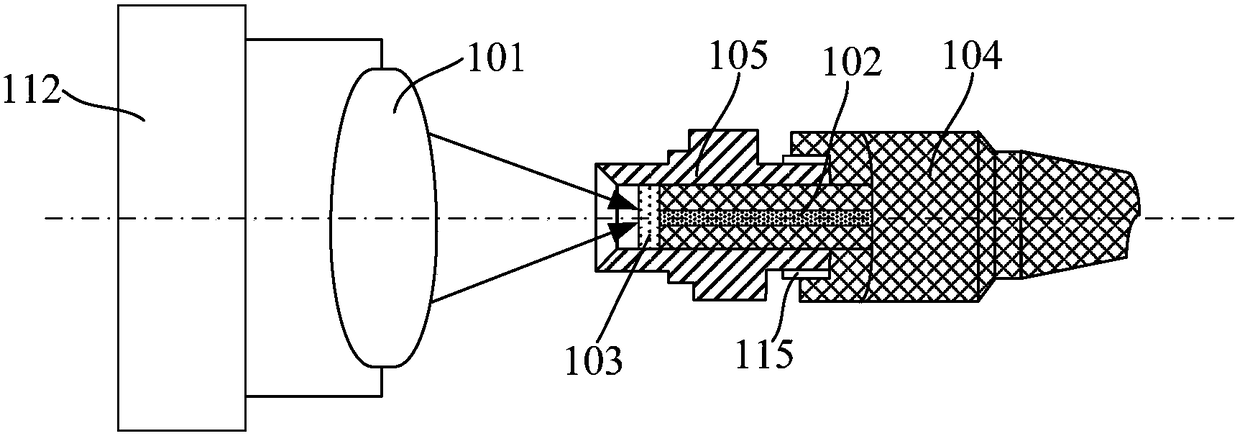

[0038] After analysis, it is found that in the coupling technology of laser and optical fiber, the relative positional relationship between laser beam and optical fiber is mainly controlled by mechanical structure. Therefore, in order to obtain high coupling efficiency, in addition to strictly satisfying the coupling conditions, the mechanical structure Accuracy is also critical.

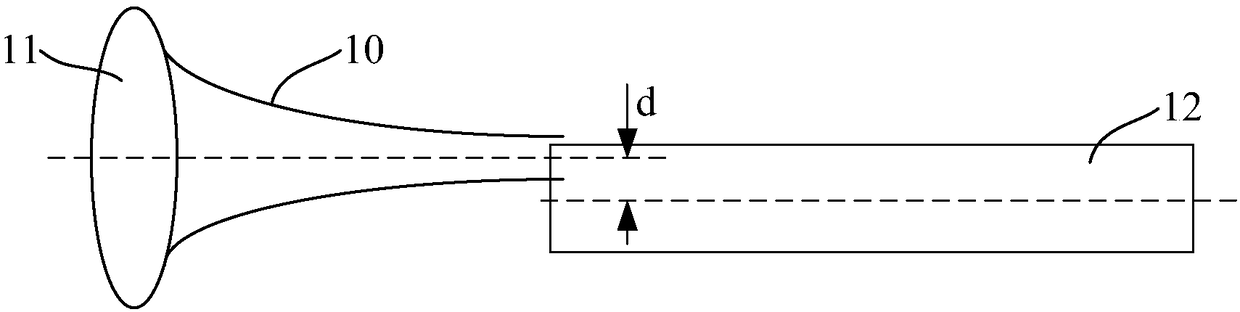

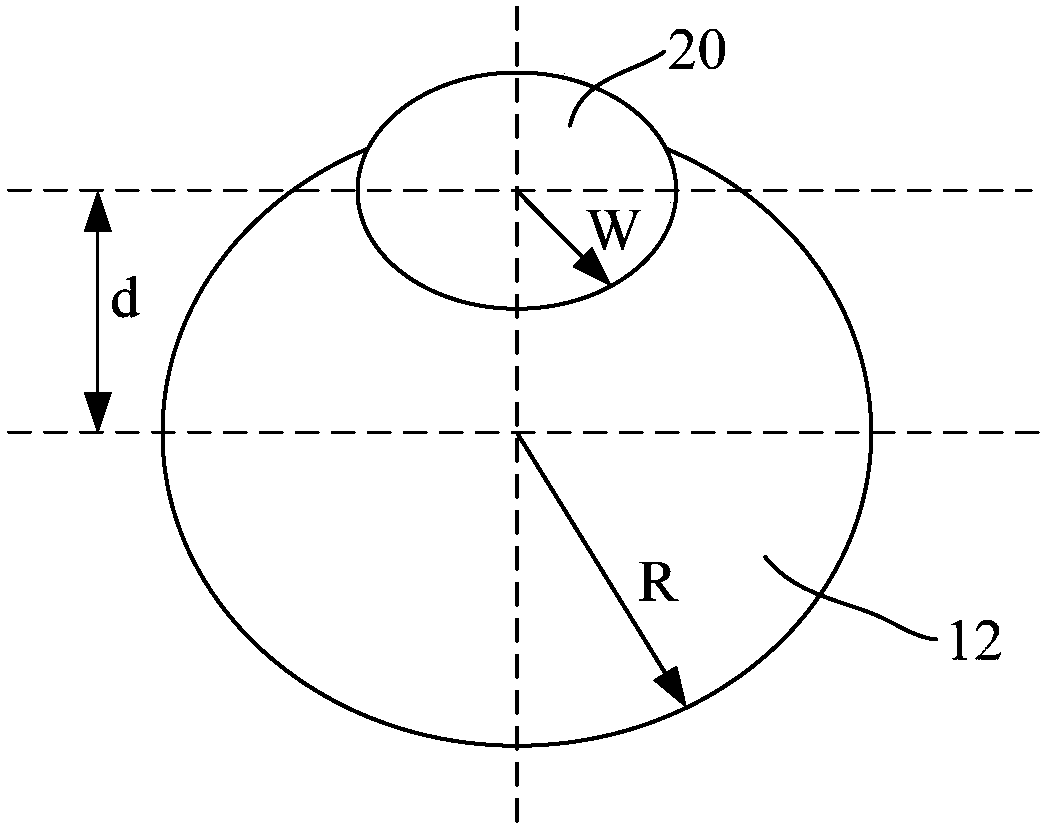

[0039] Due to the limitation of processing accuracy or the mismatch in the assembly process, it is inevitable that there will be azimuth alignment errors, mainly due to the azimuth alignment errors between the coupling mirror and the optical fiber, resulting in a decrease in coupling efficiency. The alignment error includes the lateral displacement error between the coupling mirror and the fiber, combined with the reference figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com