Method for identifying early failure root causes of products based on dimensionality reduction and support vector machine

A support vector machine, early failure technology, applied in character and pattern recognition, computer parts, instruments, etc., can solve problems such as inaccurate accuracy, redundant model training time, high early failure rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

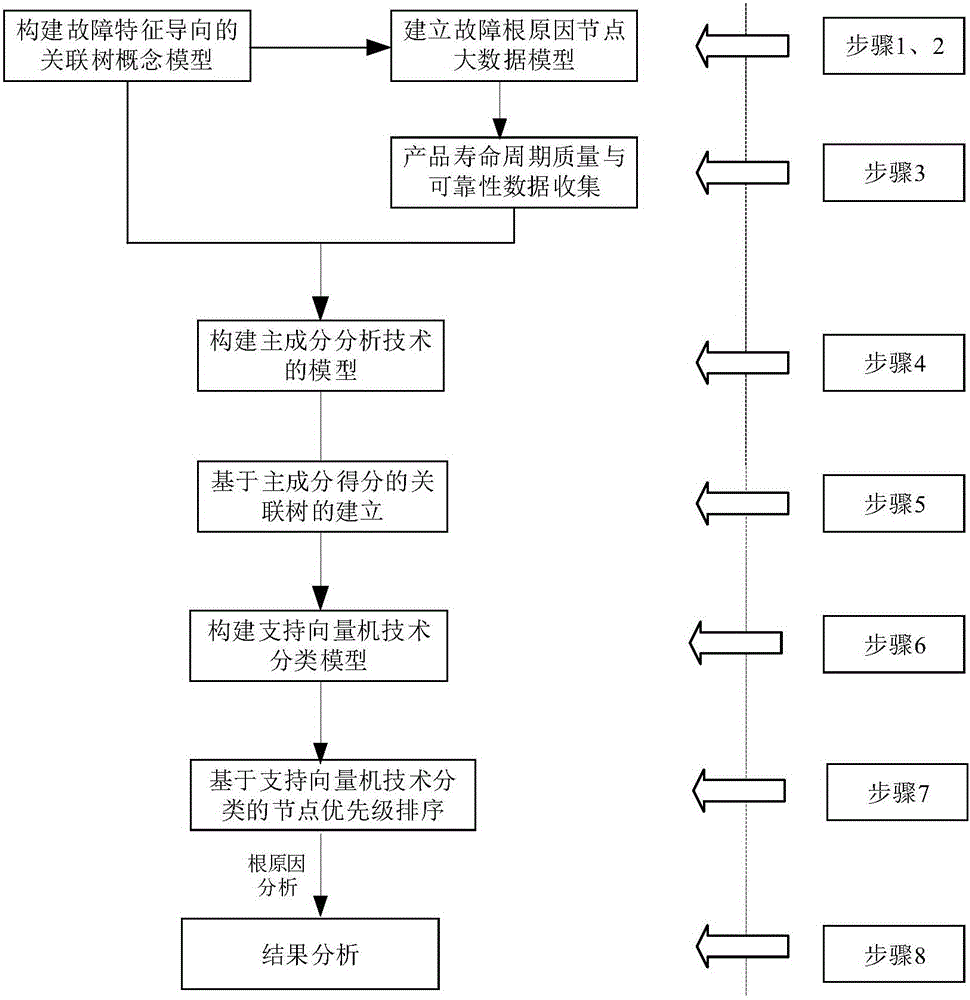

[0078] The present invention is based on dimensionality reduction and support vector machine root cause identification method for early failure of products, see figure 1 As shown, the specific steps are as follows:

[0079] Step 1. Constructing a fault feature-oriented association tree conceptual model;

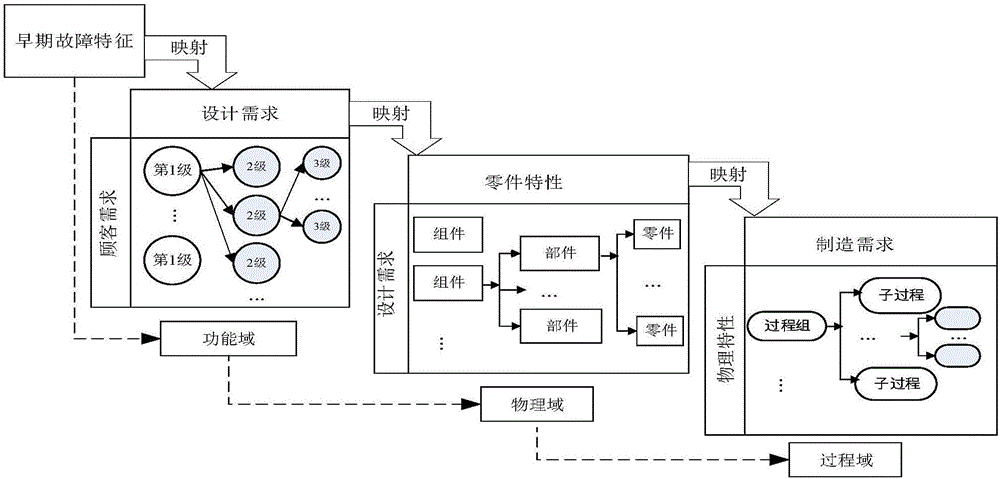

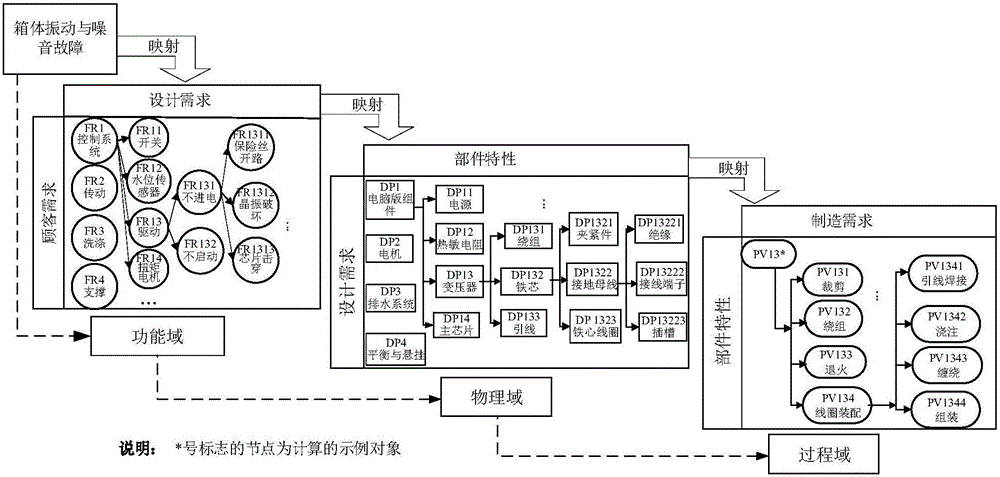

[0080] The goal of constructing the association tree is to start from the point of view of the final reliability of the product, and use the axiomatic domain mapping and waterfall decomposition theory system to build a link from design to manufacturing that may lead to early failures. Find possible nodes in the product functional domain, product physical domain and product process domain through the constructed conceptual model of the correlation tree, and finally realize the conceptual model of the fault correlation tree as follows: figure 2 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com