Mineral insulated metal sheathed fire-resistant cable, manufacturing method and application thereof

A metal sheath and mineral insulation technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of harsh manufacturing environment, short project length, and many joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

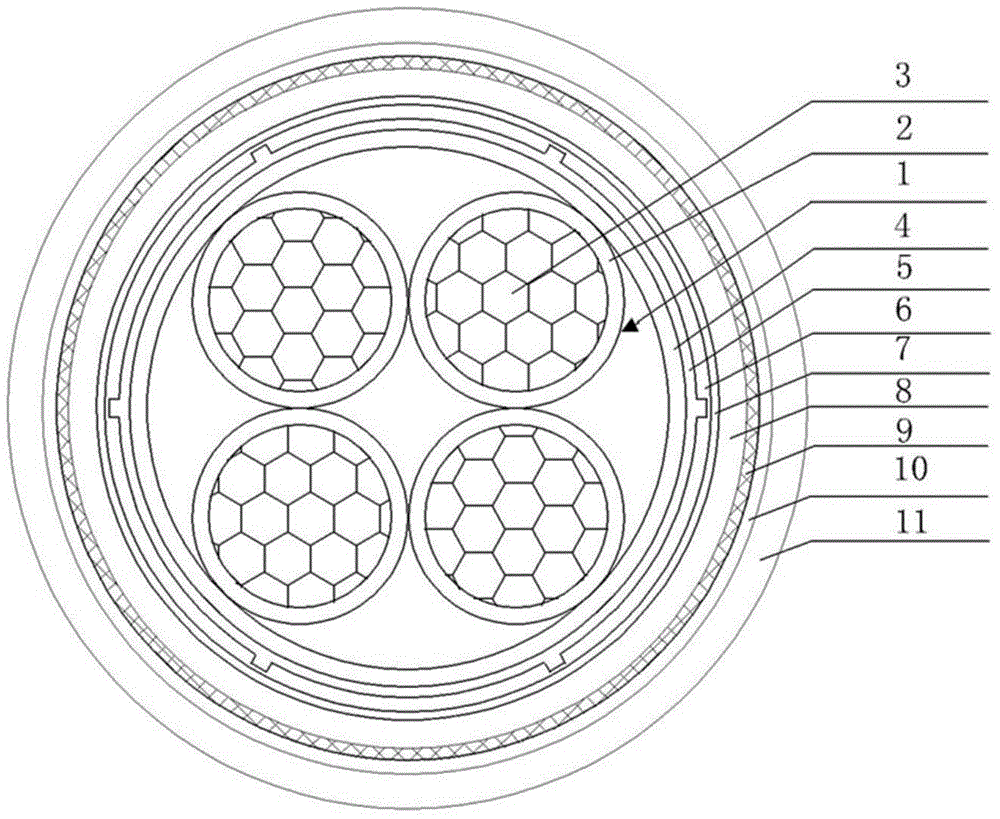

[0057] A fire-resistant cable with mineral insulated metal sheath, its cross-sectional structure is as follows figure 1 As shown, the mineral-insulated metal-sheathed fire-resistant cable is provided with four insulated wire cores 1, the outer layer of the insulated wire cores 1 is a mineral insulation layer 2 and a metal conductor 3 is arranged inside, and the aluminum metal sheath 4 is coated on the Outside the four insulated wire cores 1, the outer layer of the aluminum metal sheath 4 is sequentially coated with a tooth-shaped anti-corrosion plastic layer 5, a mineral oxygen barrier layer 6, a first flame-retardant layer 7, a mineral fire-resistant expansion layer 8, and metal reinforcement. layer 9, a second flame-retardant layer 10 and a low-smoke, halogen-free, flame-retardant outer sheath 11. Among them, the mineral insulating layer 2 is made of refractory mica material, and the thickness of the layer is 0.7mm; the metal conductor 3 is made of twisted copper monofilamen...

Embodiment 2

[0069] A fire-resistant cable with mineral insulated metal sheath, its cross-sectional structure is as follows figure 1 As shown, the mineral-insulated metal-sheathed fire-resistant cable is provided with an insulated core 1, the outer layer of the insulated core 1 is a mineral insulating layer 2 and a metal conductor 3 is provided inside, and an aluminum metal sheath 4 is wrapped in a The outside of the root insulated wire core 1, the outer layer of the aluminum metal sheath 4 is sequentially coated with a tooth-shaped anti-corrosion plastic layer 5, a mineral oxygen barrier layer 6, a first flame-retardant layer 7, a mineral fire-resistant expansion layer 8, and a metal reinforcement layer 9. The second flame-retardant layer 10 and the low-smoke, halogen-free flame-retardant outer sheath 11 . Among them, the mineral insulating layer 2 is made of refractory mica material, and the layer thickness is 1.8mm; the metal conductor 3 is made of twisted copper monofilament, and the c...

Embodiment 3

[0081] A fire-resistant cable with mineral insulated metal sheath, its cross-sectional structure is as follows figure 1 As shown, the mineral insulated metal sheathed fire-resistant cable is provided with five insulated wire cores 1, the outer layer of the insulated wire cores 1 is a mineral insulation layer 2 and a metal conductor 3 is arranged inside, and the aluminum metal sheath 4 is coated on the The outside of the five insulated wire cores 1 and the outer layer of the aluminum metal sheath 4 are sequentially coated with a tooth-shaped anti-corrosion plastic layer 5, a mineral oxygen barrier layer 6, a first flame-retardant layer 7, a mineral fire-resistant expansion layer 8, and metal reinforcement layer 9, a second flame-retardant layer 10 and a low-smoke, halogen-free, flame-retardant outer sheath 11. Among them, the mineral insulating layer 2 is made of refractory mica material, and the thickness of the layer is 0.4mm; the metal conductor 3 is made of twisted copper m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com