A method for continuous printing to prepare supercapacitors

A supercapacitor and electrode technology, applied in the field of electrochemistry, can solve the problems of integration, inability to realize continuous preparation of supercapacitors, undesignable shape of supercapacitors, etc., and achieve the effects of controllable thickness, fast preparation speed and adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

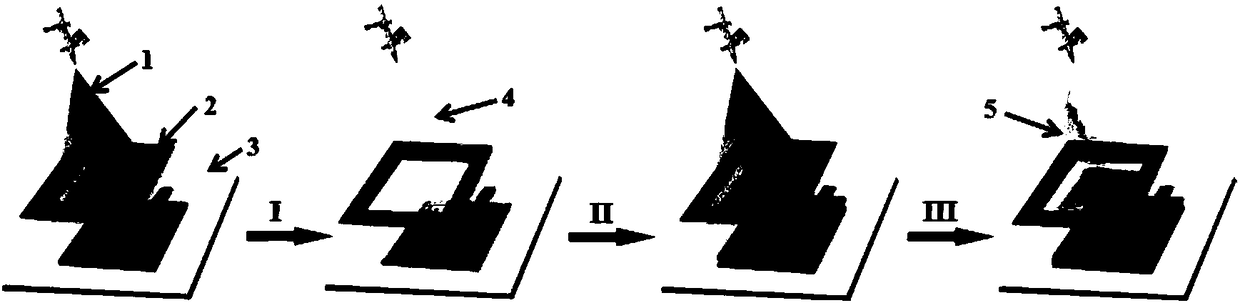

[0033] Taking the spray printing method as an example, the present invention integrates various components of the supercapacitor, including electrode materials, diaphragms, and electrolytes, onto the same substrate, and the entire preparation process is continuously controllable.

[0034] figure 1 It is a schematic diagram of using carbon nanotubes as raw materials to prepare supercapacitors by spray printing. The dispersed electrode material solution is atomized and sprayed out through a spray gun, and the electrode material is sprayed 1, and deposited on the substrate through a baffle plate of a specific shape. 3. After the solvent is volatilized, a thin film of the electrode material is formed. The thickness of the electrode material film is 1 μm; then, the dispersed nanofiber solution is atomized and sprayed with a spray gun, and evenly covered on the surface of the electrode material, and the nanofiber Primer spray 4, after the solvent is volatilized, a uniform nanofiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com