Double-sided power generation double-glass assembly

A technology of double-glass modules and double-sided cells, which is applied in the field of solar photovoltaic power generation, can solve problems such as low module efficiency, lower module output power, and poor module reliability, so as to increase the effective power generation area, improve conversion efficiency, and module appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

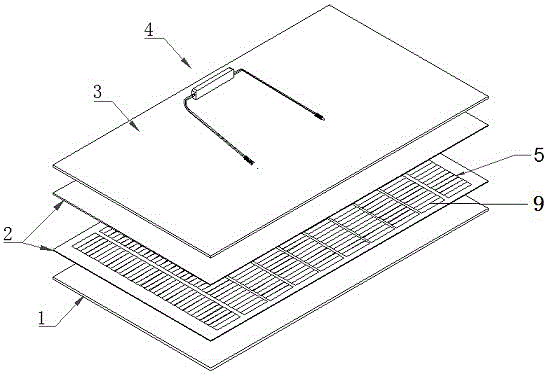

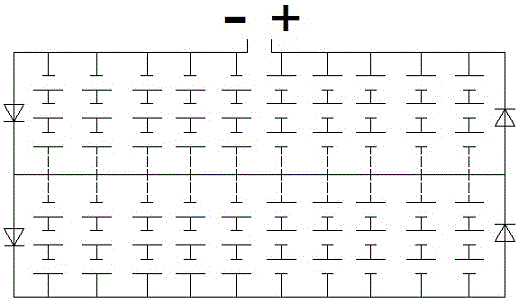

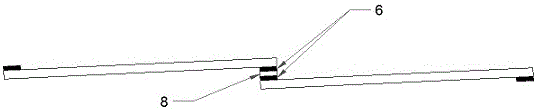

[0019] As shown in the figure, a double-sided power generation double-glass component according to the present invention, the components are front glass 1, front hot-melt adhesive film 2, solar cell string 5, rear hot-melt adhesive film 2 and printing from top to bottom. Porous glass 3, solar cell string 5 is provided with several double-sided cells, the surface of the double-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com