Freshwater shrimp feed and preparation method thereof

A feed, green shrimp technology, applied in animal feed, animal feed, climate change adaptation and other directions, can solve the problems of unreasonable ratio of raw materials, increased breeding costs, and high bait coefficients, reducing breeding costs, expanding market share, and improving feed High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

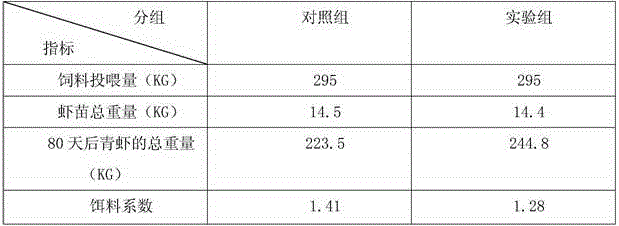

Examples

Embodiment 1

[0018] A freshwater shrimp feed, in parts by weight, consists of the following components: 22 parts of imported fish meal, 22 parts of soybean meal, 18 parts of cotton meal, 16 parts of vegetable cake, 12 parts of rapeseed meal, 7 parts of DDGS, 12 parts of a starch, phosphorus 2 parts of calcium, 0.4 parts of choline, 1.5 parts of binder, 1.5 parts of premix, 0.15 parts of shelling agent, 0.8 parts of salt, and 1.5 parts of rapeseed oil.

[0019] A kind of preparation method of freshwater shrimp feed of present preferred embodiment, comprises the steps:

[0020] (1) Grinding soybean meal, cotton meal, vegetable cake, rapeseed meal, DDGS, α-starch, phosphorus calcium, choline, premix, and shelling into powder, mixed to obtain mixed powder, and set aside;

[0021] (2) Add imported fish meal, binder, salt, vegetable oil to the mixed powder obtained in step (1), fully stir with a mixer to obtain a semi-finished product;

[0022] (3) Put the semi-finished product into a steamer f...

Embodiment 2

[0025] A freshwater shrimp feed, in parts by weight, consists of the following components: 20 parts of imported fish meal, 20 parts of soybean meal, 16 parts of cotton meal, 15 parts of vegetable cake, 10 parts of rapeseed meal, 6 parts of DDGS, 10 parts of a starch, phosphorus 1.5 parts of calcium, 0.3 parts of choline, 1 part of binder, 1 part of premix, 0.1 part of shelling agent, 0.5 part of salt, and 1 part of vegetable oil.

[0026] The preparation method of a freshwater shrimp feed in this embodiment is the same as in Embodiment 1, so it will not be repeated.

Embodiment 3

[0028] A freshwater shrimp feed, in parts by weight, consists of the following components: 21 parts of imported fish meal, 19 parts of soybean meal, 17 parts of cotton meal, 16 parts of vegetable cake, 11 parts of rapeseed meal, 5 parts of DDGS, 10 parts of a starch, phosphorus 1 part of calcium, 0.2 part of choline, 1.5 parts of binder, 0.8 part of premix, 0.08 part of shelling agent, 0.6 part of salt, 1.2 parts of rapeseed oil.

[0029] The preparation method of a freshwater shrimp feed in this embodiment is the same as in Embodiment 1, so it will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com