Full-automatic sole polisher

A fully automatic, grinding machine technology, applied in shoe-making machinery, grinding machine parts, footwear, etc., can solve the problems of difficulty in ensuring product quality, consuming manpower and material resources, and large influencing factors, achieving reliable operation and saving. The effect of working hours, loading and unloading is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

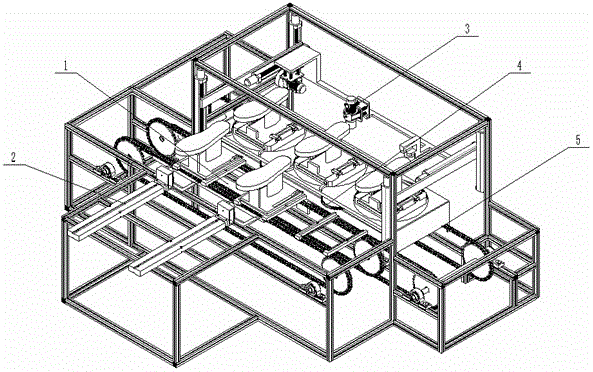

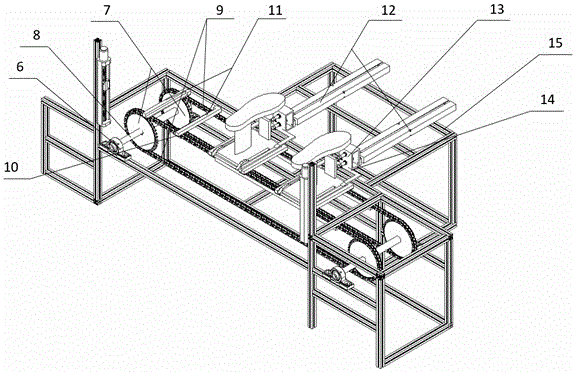

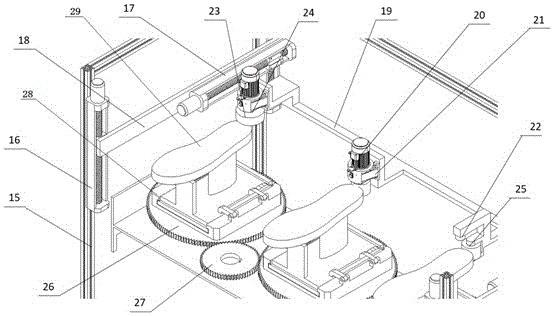

[0015] Example. Fully automatic shoe sole grinding machine, composed of figure 1 As shown, it includes chain conveying unit 1, cylinder loading and unloading unit 2, screw grinding wheel grinding unit 3, gear transmission unit 4 and chain auxiliary transmission unit 5, and the two sides of chain conveying unit 1 are respectively equipped with cylinder loading and unloading unit 2 and chain auxiliary transmission Unit 5, chain auxiliary transmission unit 5 is provided with screw grinding wheel grinding unit 3 via gear transmission unit 4; constitutes as figure 2 As shown, the chain conveying unit 1 includes two pairs of bearing housings 6 fixed on the profile frame 15, and two sprockets 7 are arranged between each pair of bearing housings 6 through the conveying shaft 8, and the chains on the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com