A catheter handle used for an implant conveying system

A delivery system and implant technology, applied in the field of minimally invasive interventional medical devices, can solve problems such as easy to hide dirt, form air thrombus, and no indication, so as to avoid the risk of dirt hiding, avoid the formation of air thrombus, The effect of external smoothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

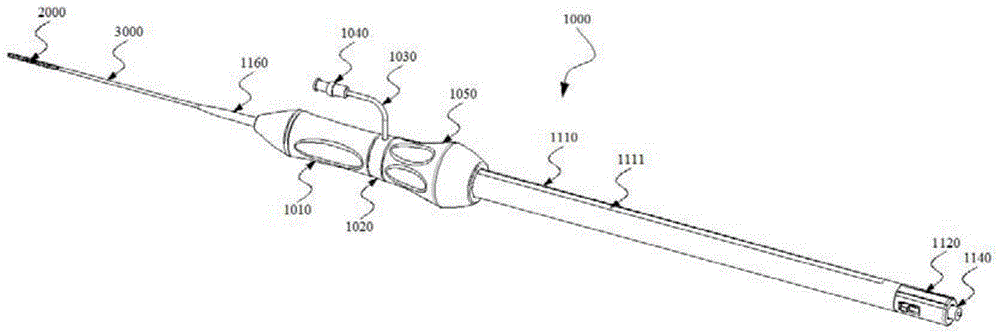

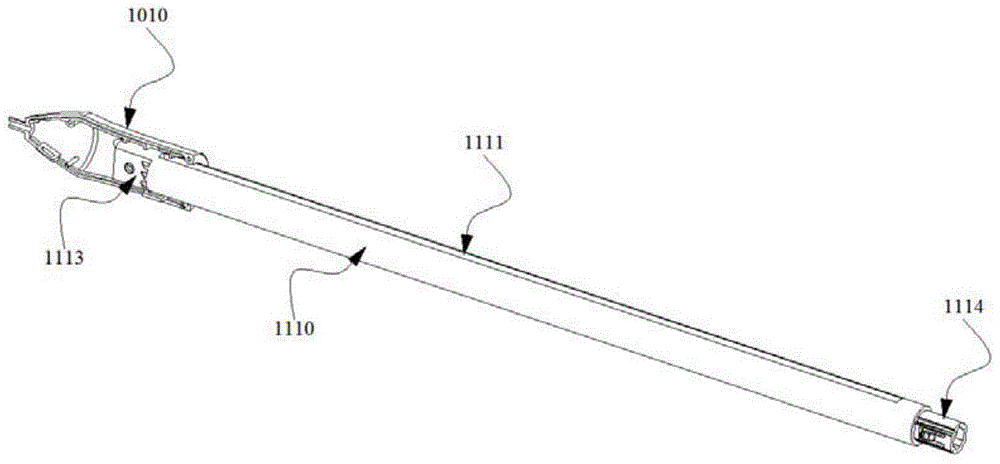

[0062] Make the stress diffusion tube 1160, the front handle 1010, the snap ring 1020, the rear handle 1050, the threaded fastener 1060, the front slider 1070, the rear slider 1080, the sliding shaft 1110, the tail end sleeve 1130 and the one-way valve by injection molding 1040;

[0063] Manufacturing shrapnel 1090 and spring 1100 by machining;

[0064] The infusion tube 1030, the outer sheath tube 3000 and the push tube 6000 are produced by extrusion molding;

[0065] The nickel-titanium alloy self-expanding stent 2000 was fabricated by laser cutting, heat treatment and electrochemical polishing;

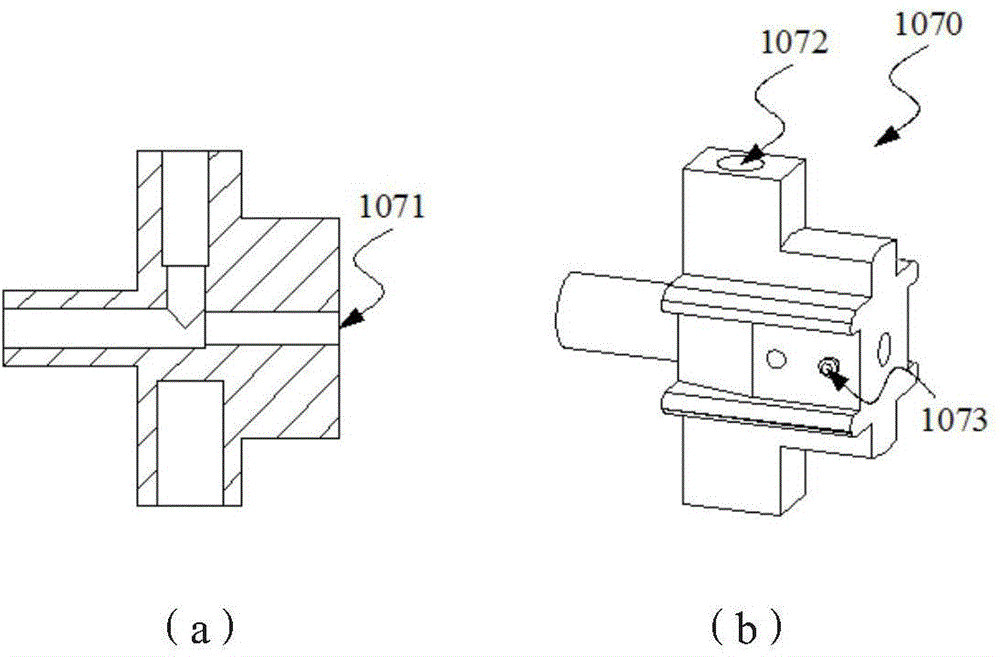

[0066] One end of the infusion tube 1030 is bonded to the one-way valve 1040 with glue, and the other end passes through the snap ring hole 1021 of the snap ring 1020 ( Figure 9 ) and then use glue to bond the front slider 1070; use glue to bond one end of the outer sheath 3000 to the front slider 1070, and pre-compress the self-expanding stent 2000 into the other end of the out...

Embodiment 2

[0075] The stress diffusion tube 1160, the front handle 1010, the snap ring 1020, the rear handle 1050, the threaded fixing piece 1060, the front slider 1070, the rear slider 1080, the sliding shaft 1110, the tail end sleeve 1120, and the one-way valve are produced by injection molding 1040;

[0076] Manufacturing shrapnel 1090 and spring 1100 through machining;

[0077] The infusion tube 1030, the outer sheath tube 3000, and the push tube 6000 are produced by extrusion molding;

[0078] The nickel-titanium alloy self-expanding stent 2000 was fabricated by laser cutting, heat treatment and electrochemical polishing;

[0079] One end of the infusion tube 1030 is bonded to the one-way valve 1040 with glue, and the other end passes through the snap ring hole 1021 of the snap ring 1020 ( Figure 9 ) after bonding with the front slider 1070 with glue; glue one end of the outer sheath tube 3000 with the front slider 1070, and pre-compress the self-expanding stent 2000 into the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com