Method for obtaining wolfberry fruit extract through multistage countercurrent extraction by adopting centrifugal extractor

A centrifugal extractor and extraction technology, which is applied in the field of multi-stage countercurrent extraction of wolfberry seed extract by centrifugal extractor, can solve the problems of low extraction efficiency, cumbersome setting process, and difficult operation, and achieve shortened extraction time, sweet and moist Soft, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

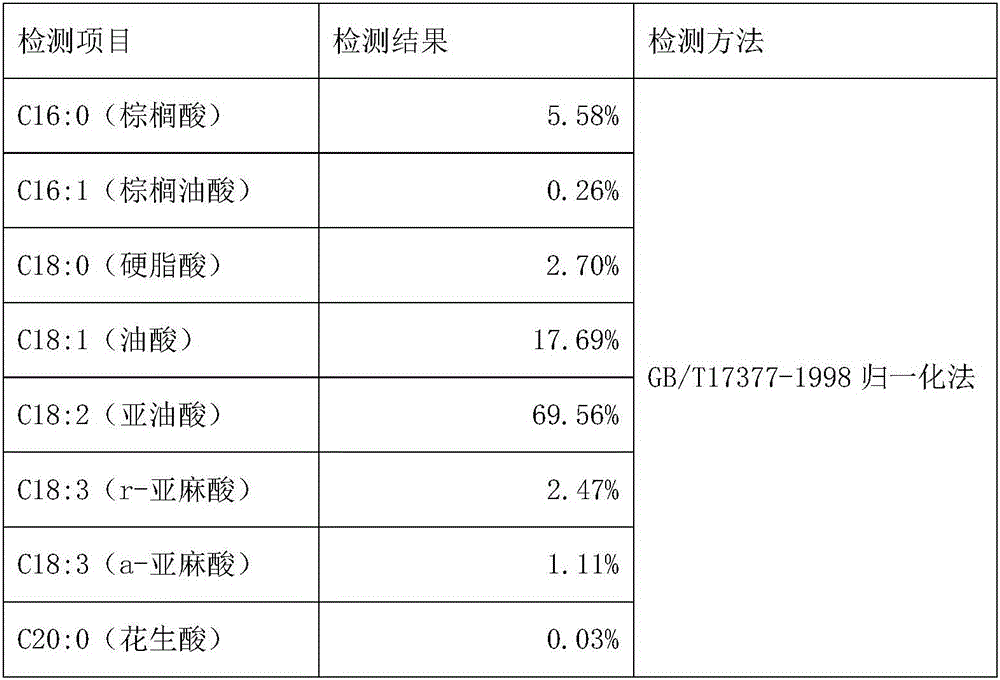

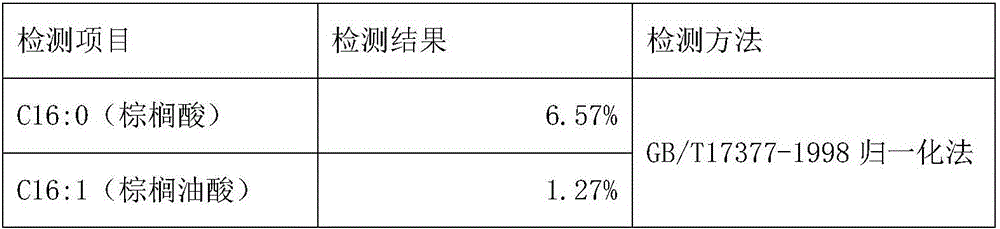

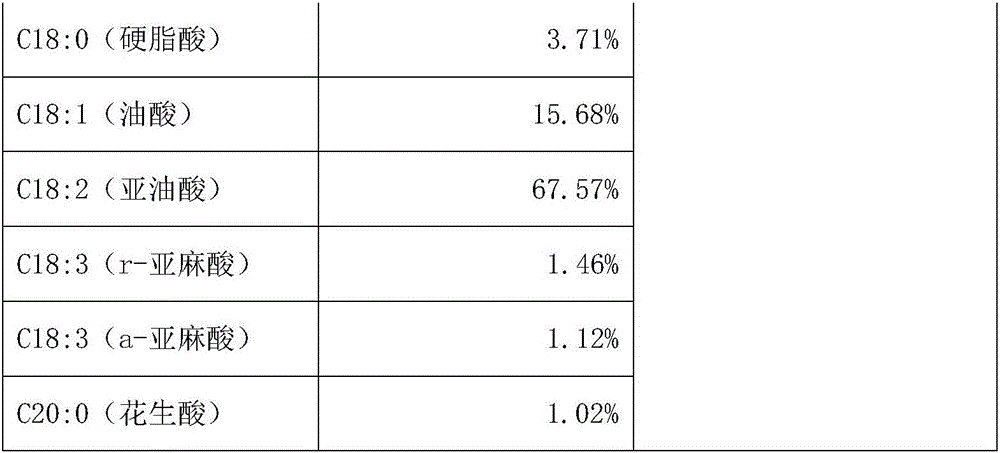

Embodiment 1

[0028] Example 1. A method for multi-stage countercurrent extraction of wolfberry seed extract using a centrifugal extractor, including the following steps;

[0029] Pretreatment steps: Dry the maca rhizome at 78°C, then crush it with a Chinese medicine crusher, crush to 60 mesh, then sieving, drying, fire roasting, and cooling to room temperature;

[0030] Extraction step: Put the petroleum ether solvent, ethanol solvent and the pretreated crushed maca rhizomes into a continuous countercurrent centrifugal extractor, vacuum the continuous countercurrent centrifugal extractor, the solvent ratio is 1:1, and the temperature At 10℃, the extraction pressure is the saturated vapor pressure of the solvent used at the corresponding temperature, and then stir while passing ultrasonic waves. The extraction time is 1.5 hours. The solid and liquid phases are separated by filtration, and the liquid phase mixed solution is transported into the temporary storage tank. Complete a soak extraction; ...

Embodiment 2

[0035] Example 2. A method for multi-stage countercurrent extraction of wolfberry seed extract using a centrifugal extractor, including the following steps;

[0036] Pretreatment steps: Dry the maca rhizome at 80°C, then crush it with a Chinese medicine crusher, crush to 80 mesh, then sieving, drying, fire roasting, and cooling to room temperature;

[0037] Extraction step: Put the petroleum ether solvent, ethanol solvent and the pretreated crushed maca rhizomes into a continuous countercurrent centrifugal extractor, vacuum the continuous countercurrent centrifugal extractor, the solvent ratio is 1.5:1, and the temperature The extraction pressure is 50℃, the extraction pressure is the saturated vapor pressure of the solvent used at the corresponding temperature, and then it is stirred while passing ultrasonic waves. The extraction time is 3 hours. The solid and liquid phases are separated by filtration, and the liquid phase mixed solution is transported into the temporary storage ta...

Embodiment 3

[0043] Example 3. A method for multi-stage countercurrent extraction of wolfberry seed extract using a centrifugal extractor, including the following steps;

[0044] Pretreatment steps: Dry the maca rhizome at 79°C, then crush it with a Chinese medicine crusher, crush to 70 mesh, then sieving, drying, fire roasting, and cooling to room temperature;

[0045] Extraction step: Put the petroleum ether solvent, ethanol solvent and the pretreated crushed maca rhizomes into a continuous countercurrent centrifugal extractor, vacuum the continuous countercurrent centrifugal extractor, and the ratio of solvent to material is 1-1.5:1 , The temperature is 48℃, the extraction pressure is the saturated vapor pressure of the solvent used at the corresponding temperature, and then stir while passing ultrasonic waves. The extraction time is 2 hours. The solid and liquid phase are separated by filtration, and the liquid phase mixed solution is transported into the temporary storage tank Tank, comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com