Vacuum pumping protection system of asphalt reaction kettles with transport chassis

A protection system and vacuuming technology, applied in the direction of pressure vessels used in chemical processes, etc., can solve the problems of inconvenience, mixing, affecting the normal production, etc., to achieve the effect of convenient movement and prevention of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

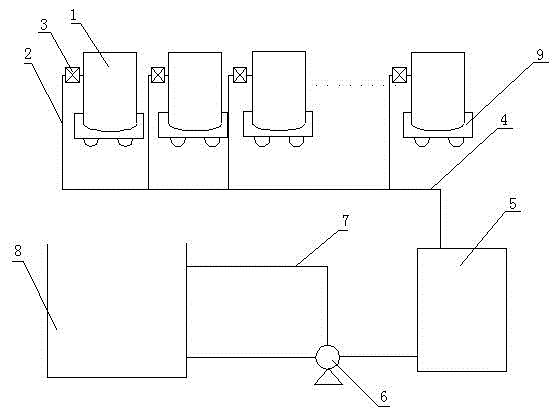

[0011] see figure 1 , the present invention relates to a vacuum protection system for an asphalt reactor with a transport base, comprising a plurality of reactors 1, each of which is provided with a transport base 9 at the bottom of the reactor 1 for moving the reactor 1, each The reaction kettle 1 is connected with a vacuum branch pipe 2, wherein each vacuum branch pipe 2 is provided with a check valve 3, and the end of each vacuum branch pipe 2 is connected to the vacuum main pipe 4, and the vacuum main pipe The end of 4 is connected with the buffer tank 5, and the buffer tank 5 is connected with the vacuum pump 6 through the pipeline, and the vacuum pump 6 is connected with the pool 8 through the water circulation pipeline 7, and a water circulation system is formed between the vacuum pump 6 and the pool 8, and the vacuum pump 6 The air extracted in the tank is discharged to the pool 8 through the water circulation pipeline 7, and finally discharged to the outside.

[0012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com