A method of graded dehydration using vibrating sieve in graphite flotation

A vibrating sieve and graphite technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of destroying the large scale rate of graphite, affecting the grinding efficiency, and the small specific gravity of graphite, so as to reduce the grinding capacity , easy to promote, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

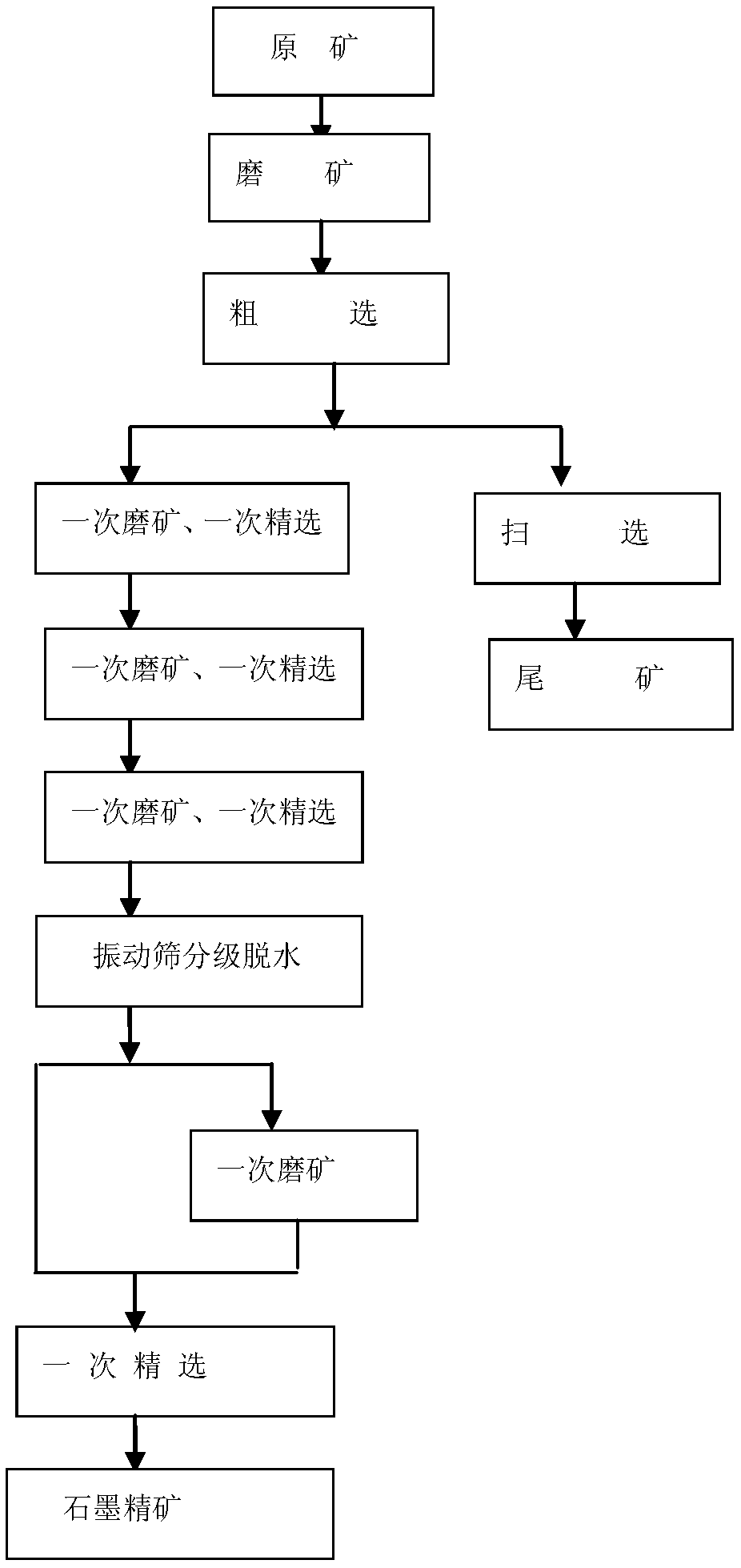

[0023] A kind of method using vibrating sieve classification dehydration in graphite flotation, it is characterized in that comprising the steps,

[0024] Step 1, the graphite raw ore is ground into the flotation operation after being ground by a ball mill, and the graphite flotation concentrate with a volume concentration of 10% obtained through three times of grinding and three times of flotation is pumped into the vibrating screen, wherein The fineness of the vibrating screen is 200 mesh;

[0025] Step 2, through the vibration of the vibrating screen, transport the graphite concentrate with a fineness greater than 200 mesh on the vibrating sieve and a volume concentration of 45% after dehydration to a ball mill for grinding, and the grinding fineness is less than 100 mesh, and the content is 68%;

[0026] Step 3, transporting the graphite concentrate after ball mill grinding in step 2 and the graphite concentrate pulp of less than 200 mesh under the vibrating screen to the ...

Embodiment 2

[0028] A kind of method using vibrating sieve classification dehydration in graphite flotation, it is characterized in that comprising the steps,

[0029] Step 1, the graphite raw ore enters the flotation operation after being ground by a ball mill, and the graphite flotation concentrate with a volume concentration of 15% obtained through three times of grinding and three times of flotation is pumped into the vibrating screen, wherein The fineness of the vibrating screen is 200 mesh;

[0030] Step 2. Through the vibration of the vibrating screen, the graphite concentrate with a volume concentration of 50% after dehydration on the vibrating screen with a fineness greater than 200 mesh is transported to a ball mill for grinding, and the grinding fineness is less than 100 mesh. The content is 71.3%;

[0031] Step 3, transporting the graphite concentrate after ball mill grinding in step 2 and the graphite concentrate pulp of less than 200 mesh under the vibrating screen to the sti...

Embodiment 3

[0033] A kind of method using vibrating sieve classification dehydration in graphite flotation, it is characterized in that comprising the steps,

[0034] Step 1, the graphite raw ore enters the flotation operation after being ground by a ball mill, and the graphite flotation concentrate with a volume concentration of 15% obtained through three times of grinding and three times of flotation is pumped into the vibrating screen, wherein The fineness of the vibrating screen is 200 mesh;

[0035] Step 2. Through the vibration of the vibrating screen, transport the graphite concentrate with a volume concentration of 55% after dehydration on the vibrating screen with a fineness greater than 200 mesh to a ball mill for grinding, and the content of which is 72% if the grinding fineness is less than 100 mesh;

[0036] Step 3, transporting the graphite concentrate after ball mill grinding in step 2 and the graphite concentrate pulp of less than 200 mesh under the vibrating screen to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com