Method for thick-wall three-way hot-press axial compensation forming with quartz powder as pressure transmission medium

A transmission medium and axial compensation technology, which is applied in the field of thick-walled three-way hot-press axial compensation molding with quartz powder as the pressure transmission medium, can solve the problems of high cost, achieve high production efficiency, shorten the construction period, and reduce the number of fires Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

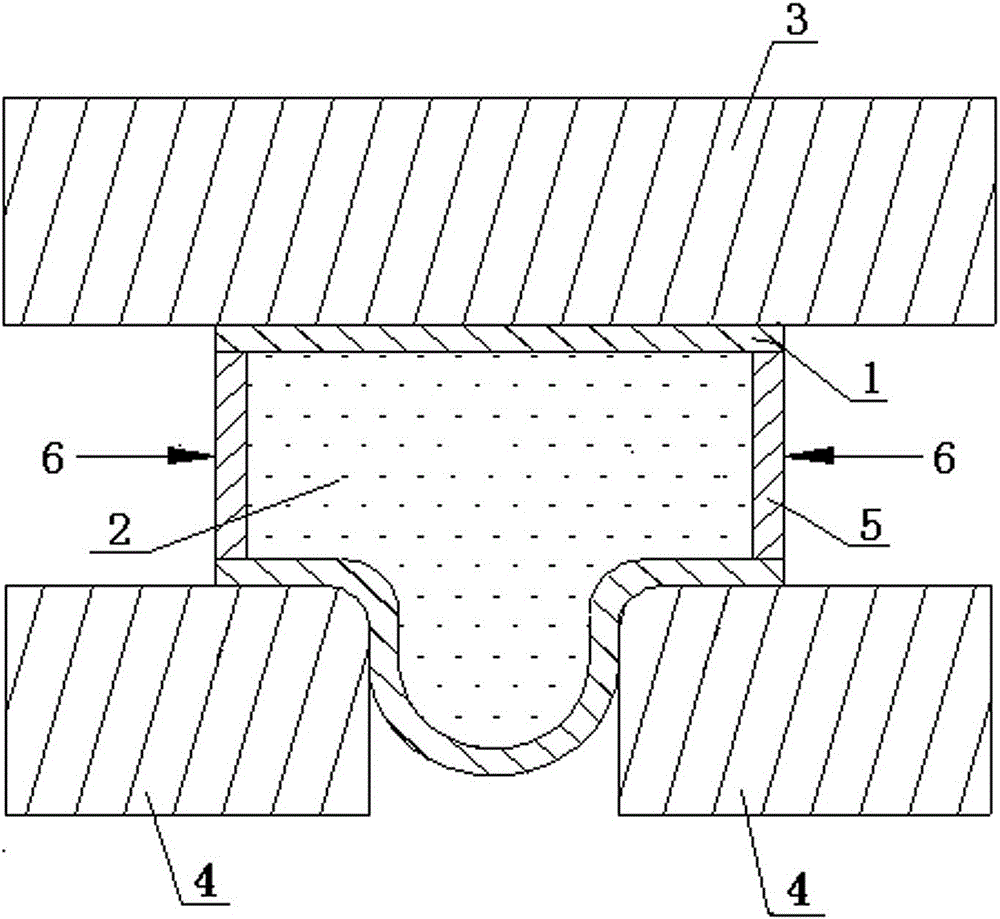

[0035] In this embodiment, the thick-walled three-way thermal pressing axial compensation molding method in which quartz powder is used as the pressure transmission medium includes the following steps:

[0036] 1) Mold preparation:

[0037] The tee mold is made of 40CrMo alloy forging. After the shape and size are processed in place, the surface hardening treatment has a hardness of HRC42;

[0038] 2) Prepare blank: material 20# steel, size: Φ420mm×47mm×1080mm;

[0039] 3) Preparation of special solid packing and charging:

[0040] The special solid filler is made of dry quartz sand of 100-140 mesh and dry graphite powder whose weight is 20% of the weight of the dry quartz sand; the filler is dried before filling, and then packed in the pipe for compaction with a 700t press ;

[0041] 4) Prepare the compensation baffle:

[0042] On the one hand, the compensation baffle is used to seal the pipe to prevent the internal medium from leaking out. On the other hand, it is used f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com