Pulse current auxiliary self-resistance heating device and method for partial quick brazing by utilizing same

A pulse current and heating device technology, which is applied in the direction of electric heating devices, welding equipment, metal processing equipment, etc., can solve the problems of large heating range, large energy consumption, uneven temperature field, etc., to improve heating efficiency, save energy consumption, Use the effect of strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

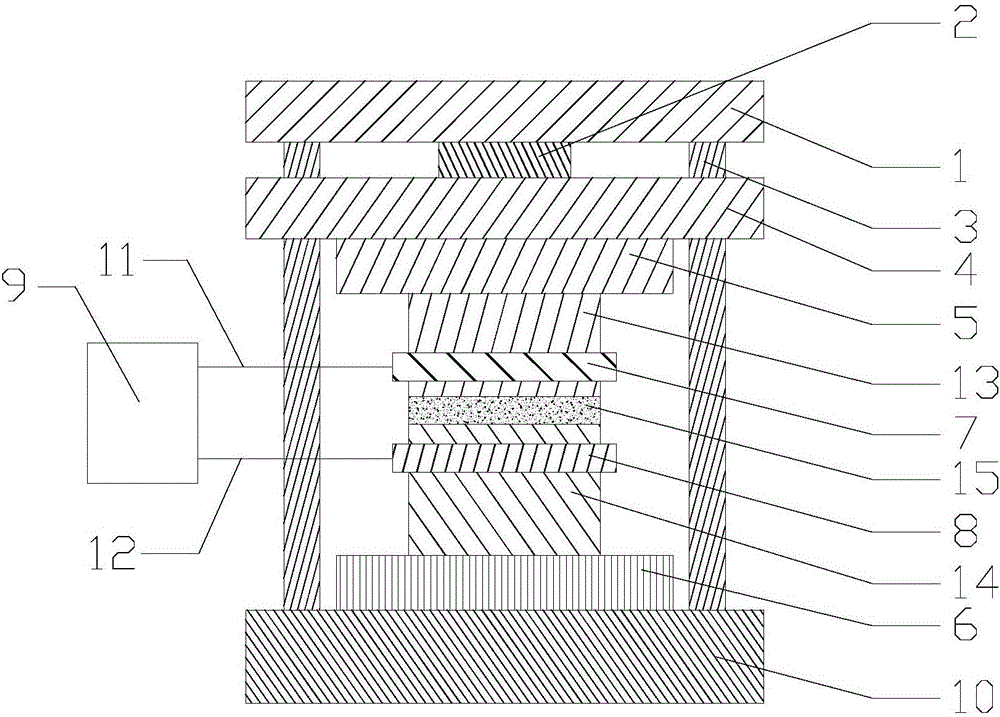

[0021] Embodiment 1: This embodiment is a pulse current assisted self-resistance heating device, which includes a press upper plate 1, a press master cylinder 2, two press guide rails 3, a press slider 4, a first ceramic insulating plate 5, The second ceramic insulating plate 6, the first electrode 7, the second electrode 8, the pulse power supply 9, the press platform 10, the first wire 11 and the second wire 12;

[0022] The upper end of the press master cylinder 2 is connected with the press upper plate 1, and the lower end of the press master cylinder 2 is connected with the press slider 4;

[0023] The two ends of the press slider 4 and the press upper plate 1 are respectively slidably connected with the two press guide rails 3;

[0024] The bottom ends of the two press guide rails 3 are fixed on the press platform 10 by bolts;

[0025] The first ceramic insulating plate 5 and the second ceramic insulating plate 6 are arranged between the two press guide rails 3, and the...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the first electrode 7 is a ring-shaped copper electrode. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the second electrode 8 is a ring-shaped copper electrode. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com