Thin-walled cylinder anti-deformation clamp and laser cladding machine for repairing cracks

A thin-walled cylinder and anti-deformation technology, applied in the field of machinery, can solve the problems of poor cylinder coaxiality, easy deformation coaxiality of cylindrical welds, etc., and achieve the effect of improving practical performance and high welding seam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

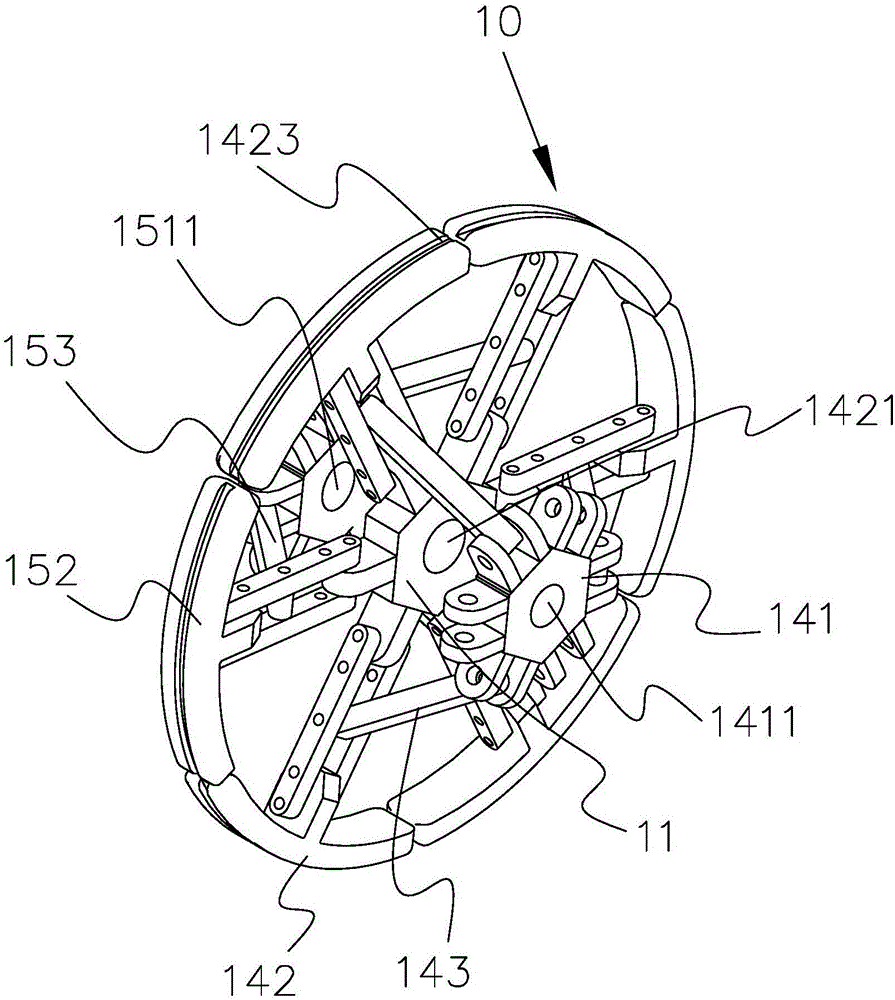

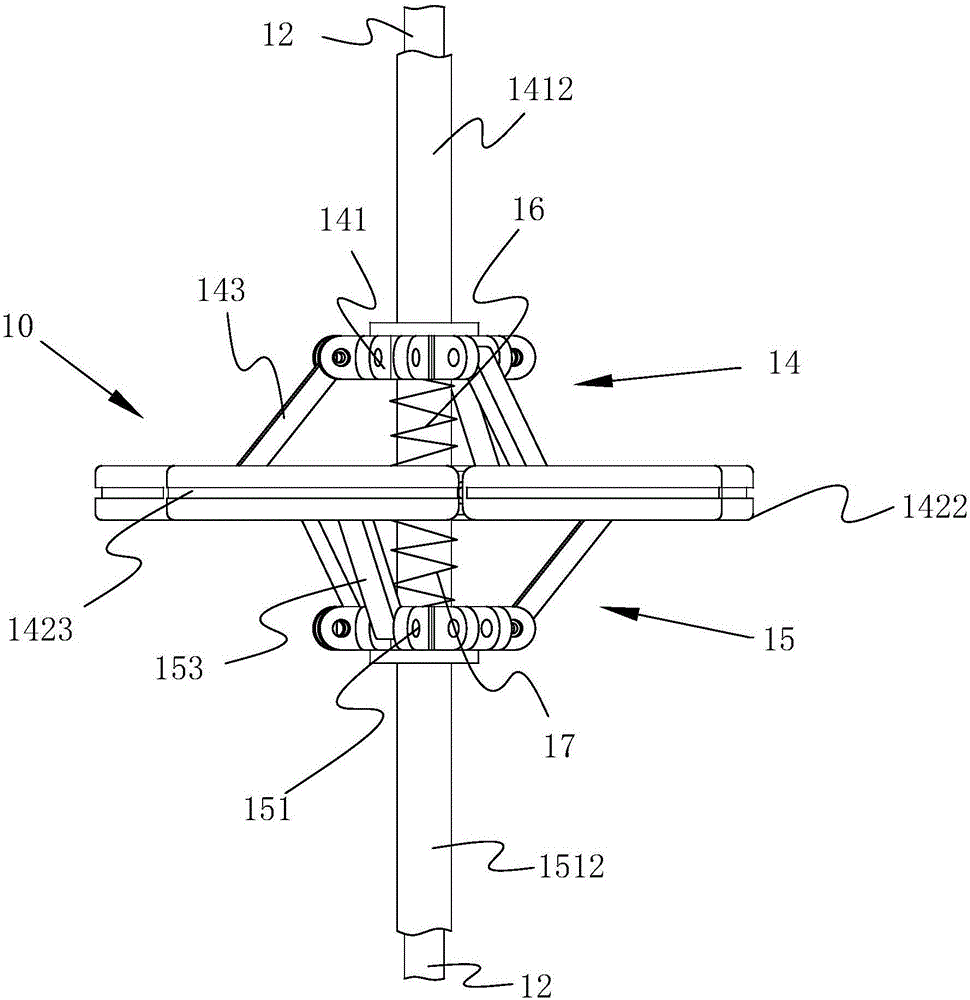

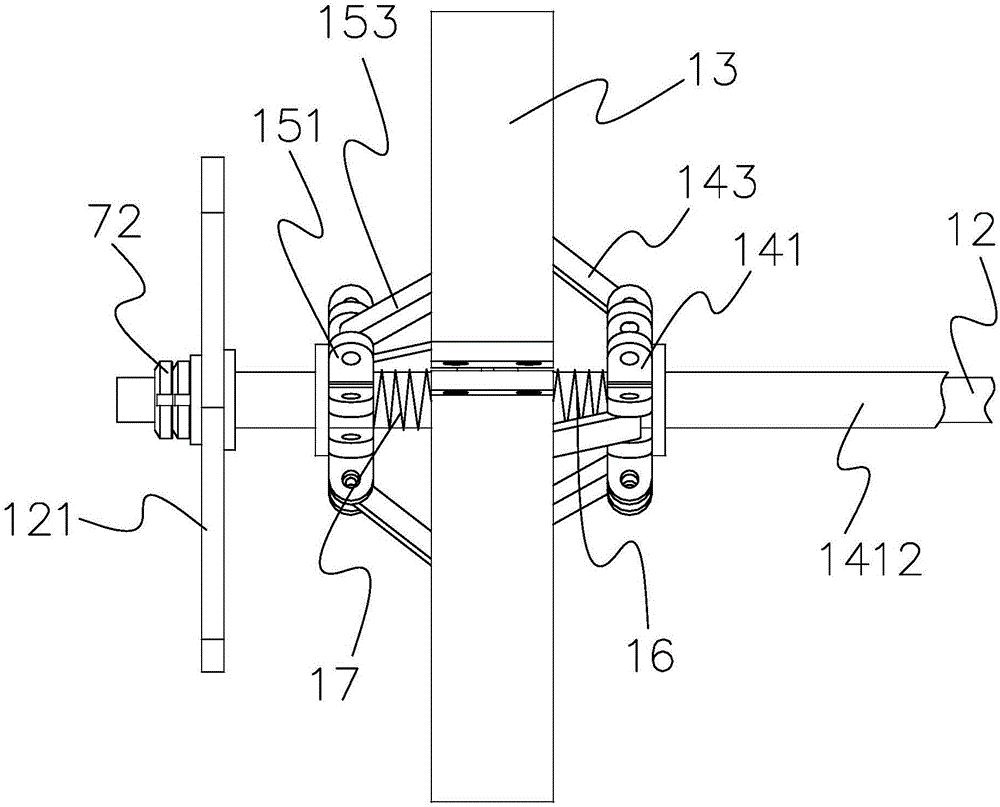

[0088] see figure 1 , figure 2 , image 3 as well as Figure 4 , a thin-walled cylindrical anti-deformation fixture of the present invention, comprising a central plate 11, a central shaft 12, an outer hoop 13, a first umbrella stand mechanism 14 and a second umbrella stand mechanism 15;

[0089] The first umbrella stand mechanism 14 includes a first end plate 141, a first support ring 142 and a first connecting rod 143, a first shaft hole 1411 is provided at the center of the first end plate, and a first shaft hole 1411 is provided at the center of the center plate. There is a second shaft hole 1421, a first push rod 1412 is arranged on the end surface of the first end plate, a first spring 16 is arranged between the center plate and the first end plate, and the first support ring and the center plate Hinged, one end of the first connecting rod is hinged at the middle of the first support ring, and the other end of the first connecting rod is hinged at the first end plate...

Embodiment 2

[0099] see Figure 6 as well as Figure 7 , the present invention provides a laser cladding machine for repairing cracks, including a thin-walled cylindrical anti-deformation fixture 10, a workbench 20, a laser 30, a controller 31 and a frame 32;

[0100] The thin-walled cylindrical anti-deformation fixture includes a central plate, a central shaft, an outer hoop, a first umbrella stand mechanism and a second umbrella stand mechanism;

[0101] The first umbrella stand mechanism includes a central plate 11, a central shaft 12, an outer hoop 13, a first umbrella stand mechanism 14 and a second umbrella stand mechanism 15;

[0102] The first umbrella stand mechanism 14 includes a first end plate 141, a first support ring 142 and a first connecting rod 143, a first shaft hole 1411 is provided at the center of the first end plate, and a first shaft hole 1411 is provided at the center of the center plate. There is a second shaft hole 1421, a first push rod 1412 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com