Crankshaft connecting rod shaft diameter processing tooling system

A technology of crankshaft connecting rod and shaft diameter, which is applied in the field of rough and finish machining fixtures for crankshaft connecting rod journals of six-cylinder engines. Speed and processing accuracy, eliminate the influence of product quality stability, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

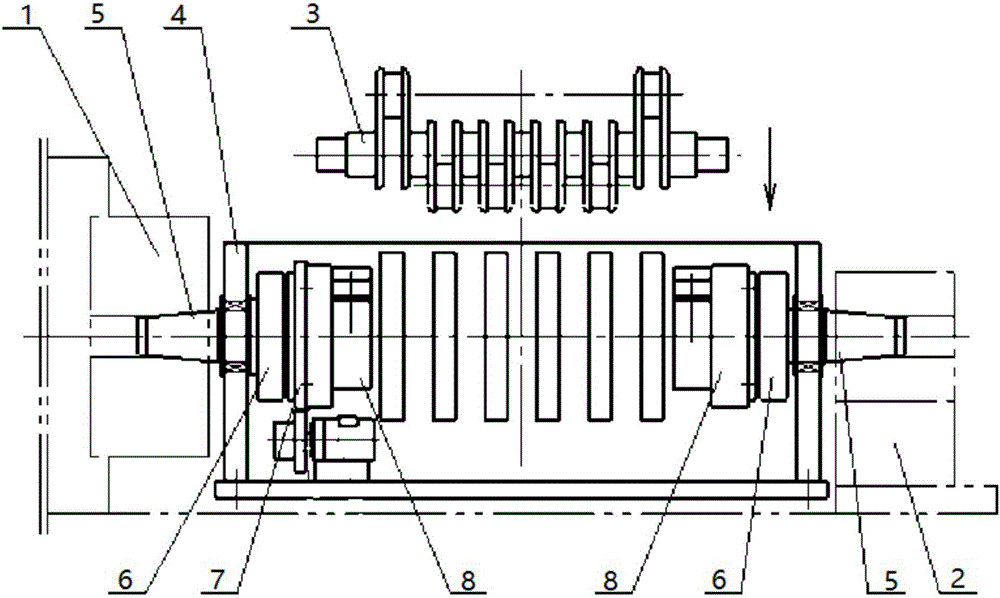

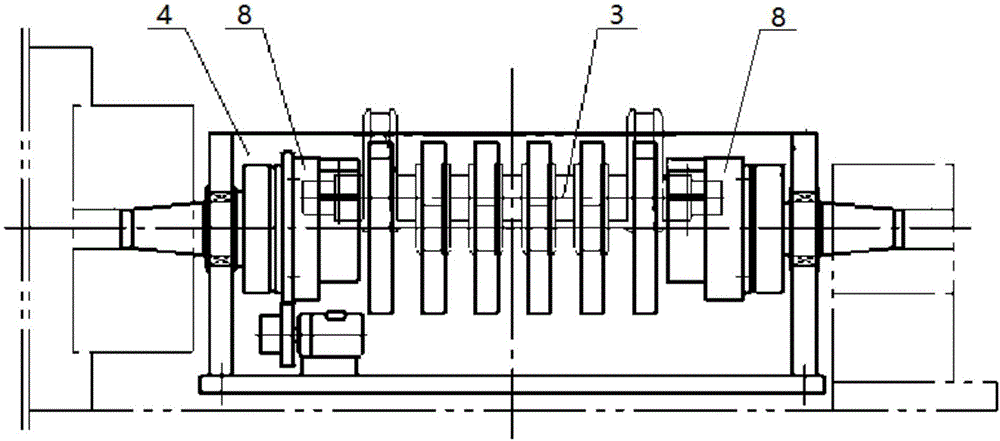

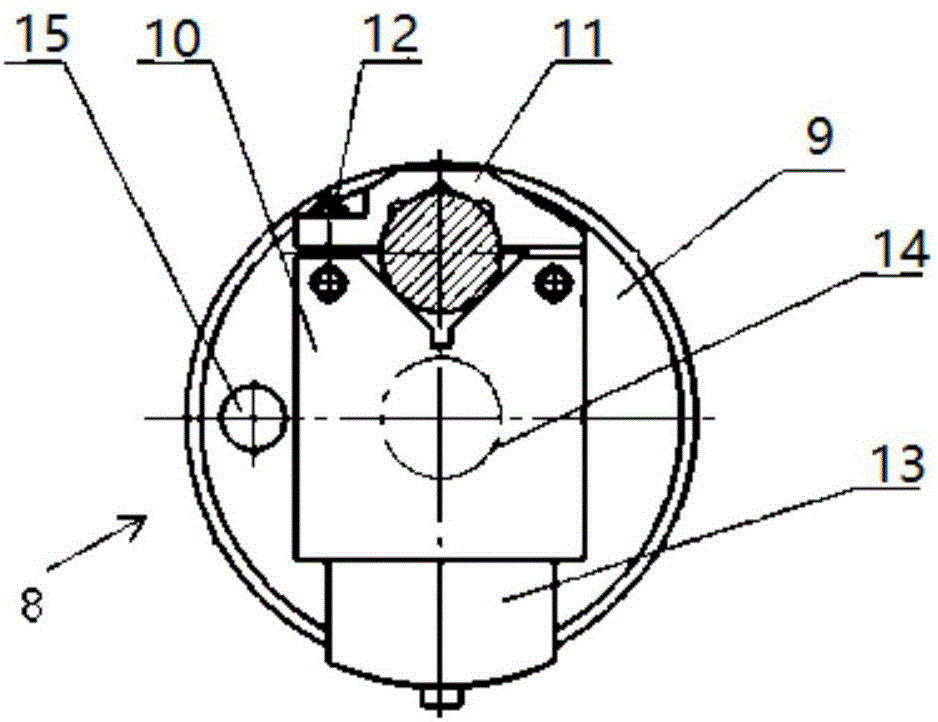

[0038] Such as Figure 1-2 As shown, the tooling system for crankshaft connecting rod shaft diameter processing includes a fixture frame 4 , a Morse taper shaft 5 , an electromagnetic clutch 6 , an indexing structure 7 and a fixture device 8 . The bottom of the fixture frame 4 is provided with a positioning surface for fixed installation with the guide rail of the machine tool. The front end of the fixture frame 4 is sequentially installed with a Morse taper shaft 5, an electromagnetic clutch 6, an indexing structure 7 and a fixture device 8 from outside to inside; the rear end of the fixture frame 4 The Morse taper shaft 5, the electromagnetic clutch 6 and the clamping device 8 are installed sequentially from outside to inside. The crankshaft 3 is placed between two clamp devices 8 and fixed using the clamp devices 8 .

[0039] The front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com