Method and device for measuring slag-iron liquid level information of hearth of blast furnace online

A blast furnace and slag iron technology, which is applied in the field of detection of blast furnace hearth conditions, can solve the problems of reading and decoding of abnormal signals of staying, and achieves the effects of long service life, improved working environment and reduced use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention are described in detail as follows:

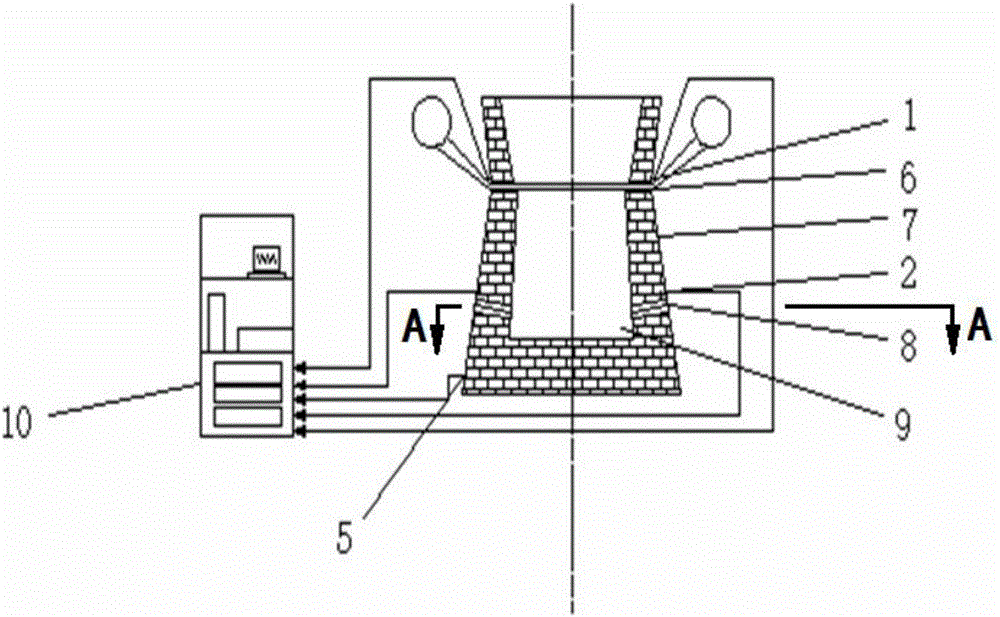

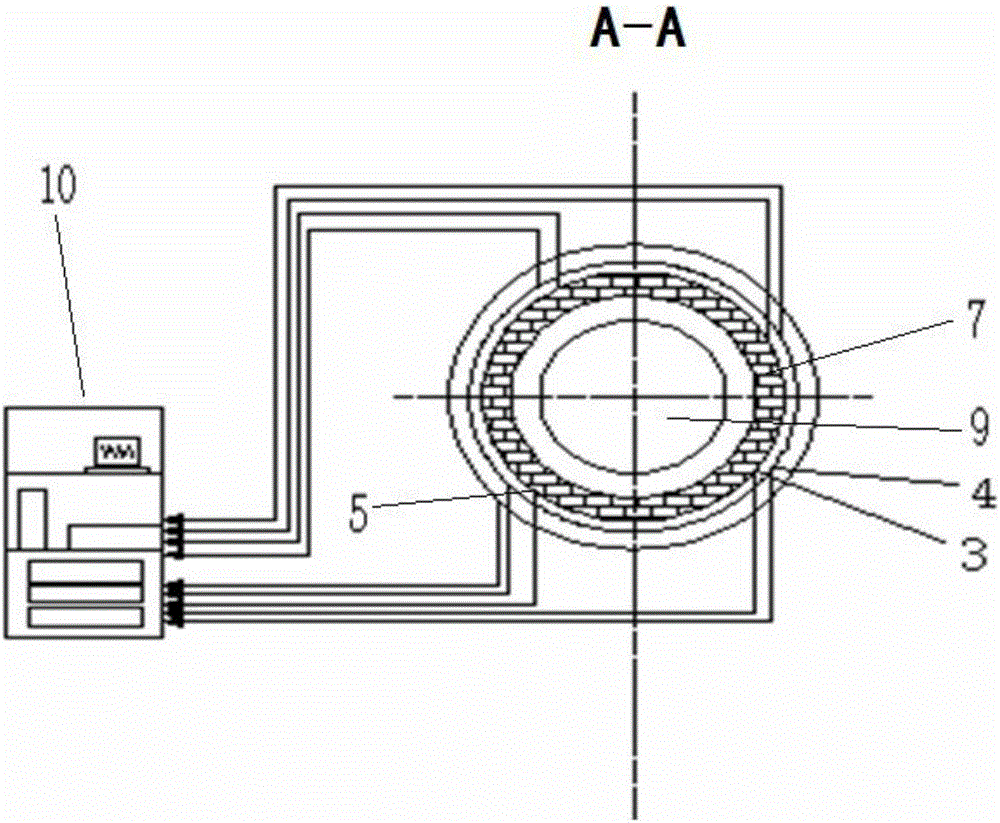

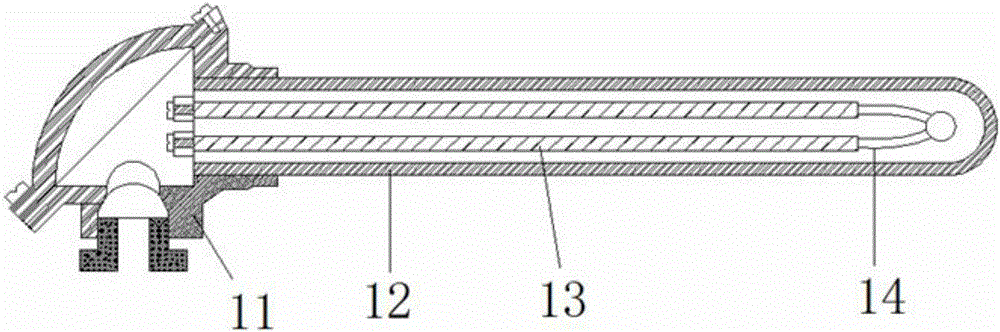

[0028] In this example, see Figure 1~3 , a device for online measurement of the liquid level information of blast furnace hearth slag and iron, including a series of electromotive force measuring points and a computer system 10, the signals collected by each electromotive force measuring point are sent to the computer system 10, and the induction terminals of the electromotive force measuring points are all set in the furnace At the set position in the refractory shell 7 of the cylinder 9, the electromotive force measurement points include the first electromotive force measurement point 1 for measuring the temperature signal of the tuyere 6 position, the second electromotive force measurement point 2 for measuring the temperature signal of the taphole 8 position, and The third electromotive force measurement point 5 of the temperature signal at the bottom of the furnace hearth 9, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com