Improved solder strip cooling liquid

A cooling liquid, an improved technology, applied in the direction of coating, metal material coating process, hot-dip plating process, etc., can solve problems affecting the quality of welding strips, achieve energy saving, prolong shelf life, and increase the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

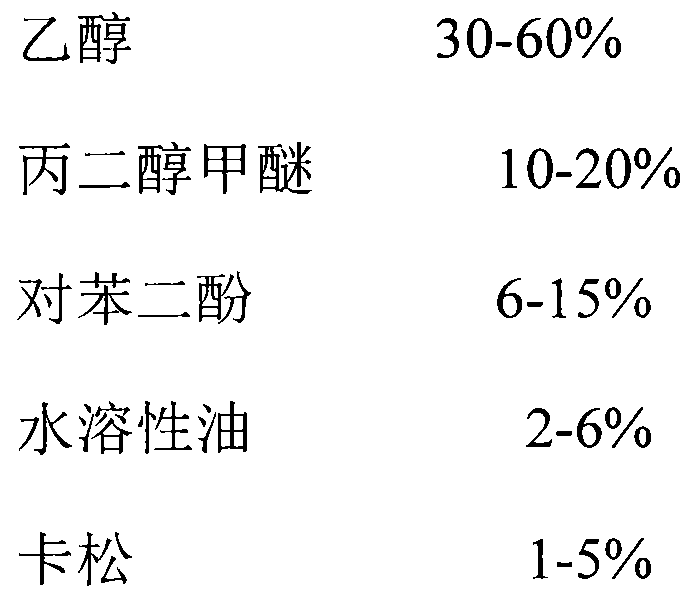

Method used

Image

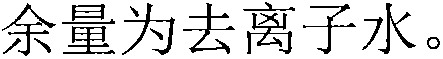

Examples

Embodiment 2

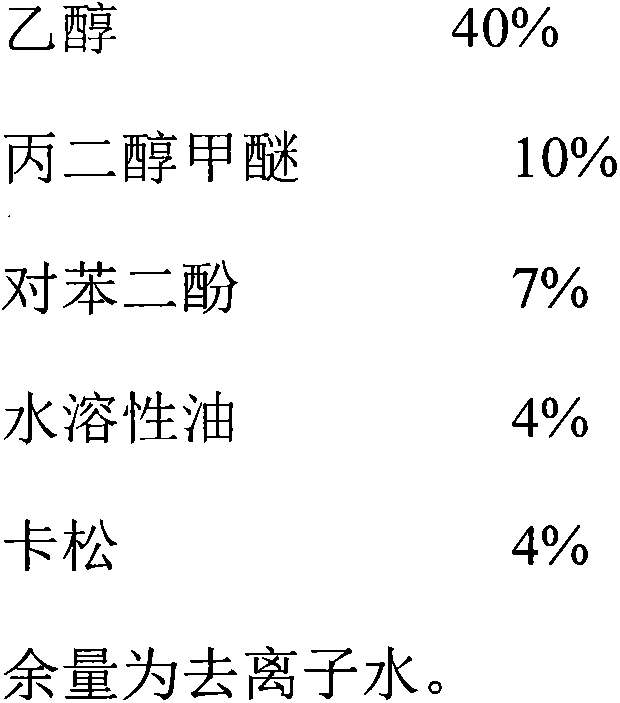

[0015] ethanol 45% Propylene Glycol Methyl Ether 15% Quinol 8% water soluble oil 4% Casson 5% The balance is deionized water.

[0016] The components in the above proportions were uniformly mixed with deionized water to obtain the ribbon cooling liquid of this embodiment.

Embodiment 3

[0018] Allyl alcohol 50% Propylene Glycol Methyl Ether 15% Quinol 8% water soluble oil 5% Casson 5% The balance is deionized water.

[0019] The components in the above proportions were uniformly mixed with deionized water to obtain the ribbon cooling liquid of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com