A coaxial nanofiber membrane embedded with fish oil and its preparation and application

A nanofiber membrane, fish oil technology, applied in fiber processing, cellulose/protein conjugated rayon, conjugated synthetic polymer rayon, etc., to improve oxidative stability, expand applications, and prolong shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

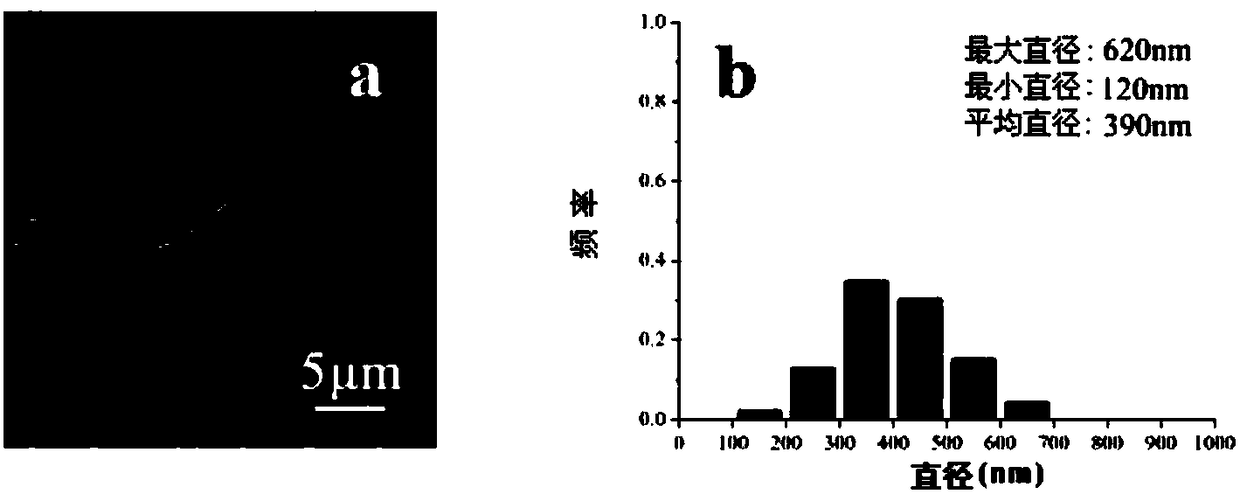

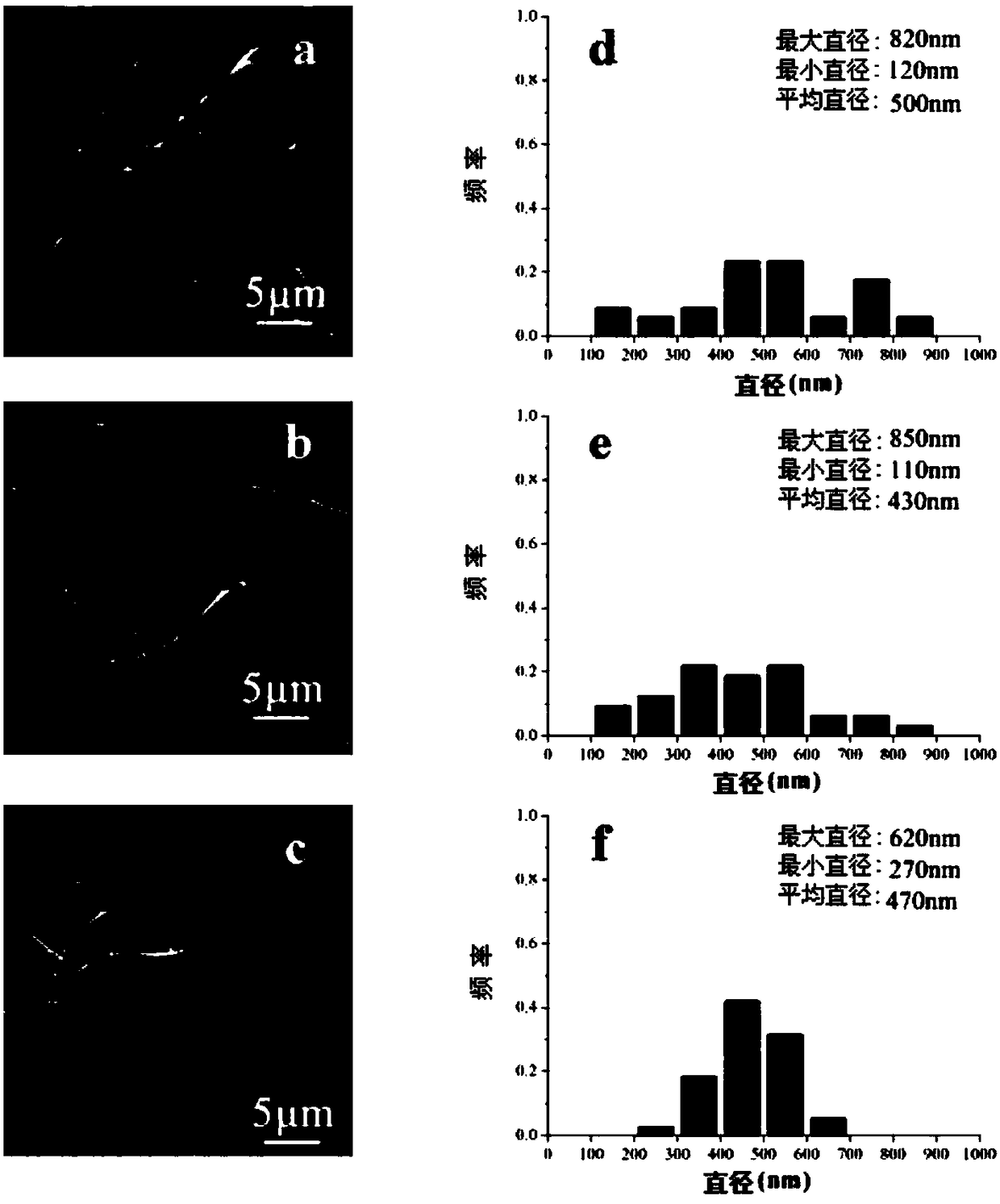

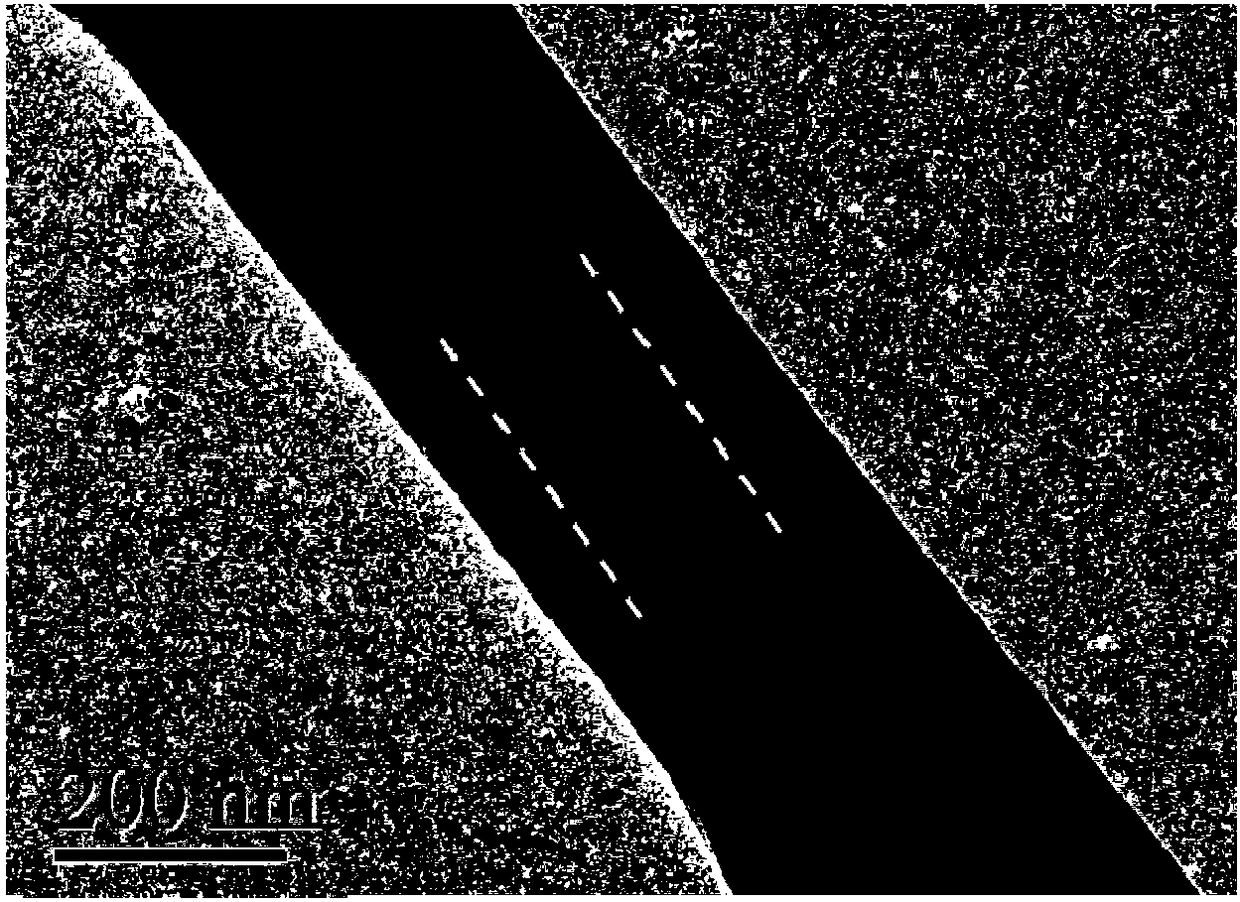

Embodiment 1

[0041] A kind of preparation method of the coaxial nanofiber film of present embodiment embedding fish oil, specifically as follows:

[0042] (1) Dissolve 31g of PVP in 100mL of ethanol and stir until completely dissolved to obtain a shell spinning solution;

[0043] (2) Dissolve 25g of zein in 100mL of ethanol:water in a mixed solvent with a volume ratio of 8.5:1.5, and stir in a magnetic stirrer for 0.5h to obtain a 25% zein solution;

[0044] (3) Add a certain amount of fish oil to the solution in step (2) according to the quality of zein: fish oil = 10:3, and stir magnetically at 25-40°C for 1 hour;

[0045] (4) adding mass fraction in the solution of step (3) is 3% glycerin, stir;

[0046] (5) Inhale the shell spinning solution obtained in step (1) into a 5mL syringe, install a needle with a diameter of 0.6mm, and control the flow rate at 0.4mL / h; suck the solution prepared in step (4) into a 5mL syringe as the core spinning solution , install a needle with a diameter o...

Embodiment 2

[0049] A kind of preparation method of the coaxial nanofiber film of present embodiment embedding fish oil, specifically as follows:

[0050] (1) Dissolve 31g of PVP in 100mL of ethanol and stir until completely dissolved to obtain a shell spinning solution;

[0051] (2) Dissolve 25g of zein in 100mL of ethanol:water in a mixed solvent with a volume ratio of 8.5:1.5, and stir in a magnetic stirrer for 0.5h to obtain a 25% zein solution;

[0052](3) Add a certain amount of fish oil to the solution in step (2) according to the quality of zein: fish oil = 10:3, and stir magnetically at 25-40°C for 1 hour;

[0053] (4) adding mass fraction in the solution of step (3) is 3% glycerin, stir;

[0054] (5) Inhale the shell spinning solution obtained in step (1) into a 5mL syringe, install a needle with a diameter of 0.6mm, and control the flow rate at 0.3mL / h; suck the solution prepared in step (4) into a 5mL syringe as the core spinning solution , install a needle with a diameter of...

Embodiment 3

[0057] A kind of preparation method of the coaxial nanofiber film of present embodiment embedding fish oil, specifically as follows:

[0058] (1) Dissolve 31g of PVP in 100mL of ethanol and stir until completely dissolved to obtain a shell spinning solution;

[0059] (2) Dissolve 25g of zein in 100mL of ethanol:water in a mixed solvent with a volume ratio of 8.5:1.5, and stir in a magnetic stirrer for 0.5h to obtain a 25% zein solution;

[0060] (3) Add a certain amount of fish oil to the solution in step (2) according to the quality of zein: fish oil = 10:3, and stir magnetically at 25-40°C for 1 hour;

[0061] (4) adding mass fraction in the solution of step (3) is 3% glycerin, stir;

[0062] (5) Inhale the shell spinning solution obtained in step (1) into a 5mL syringe, install a needle with a diameter of 0.6mm, and control the flow rate at 0.2mL / h; suck the solution prepared in step (4) into a 5mL syringe as the core spinning solution , install a needle with a diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com