Plate type low-temperature economizer

A low-temperature economizer and plate-type technology, applied in the direction of feed water heater, preheating, steam generation, etc., can solve the problems of reduced thermal performance, uneven distribution of flue gas flow field, long heat transfer stroke, etc., and increase the pressure difference The ability, easy modular assembly, and the effect of large media contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

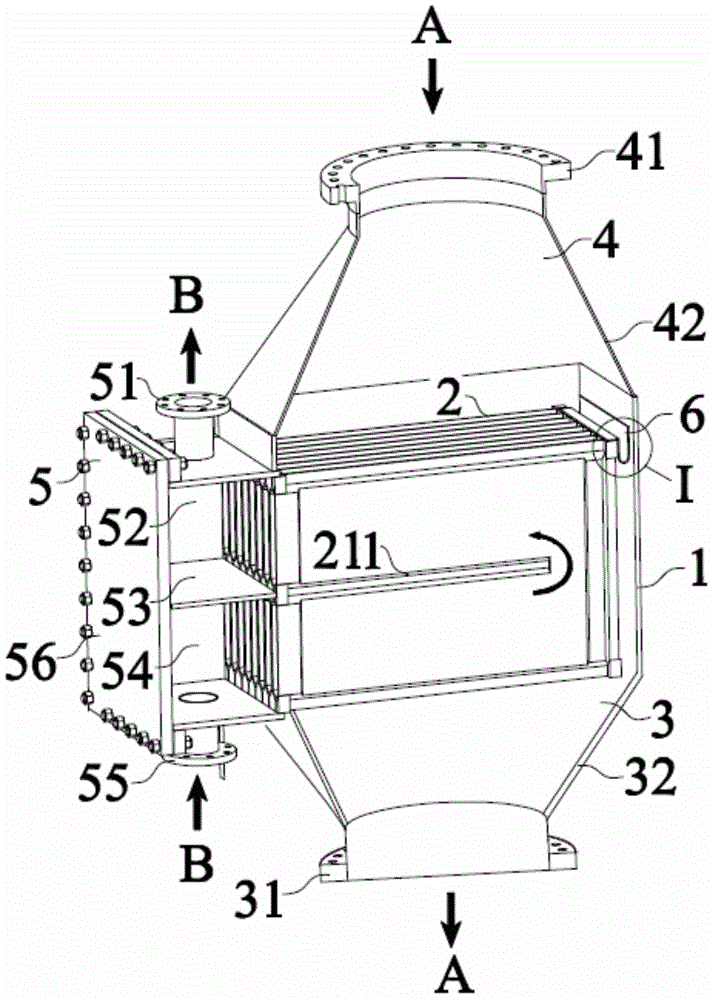

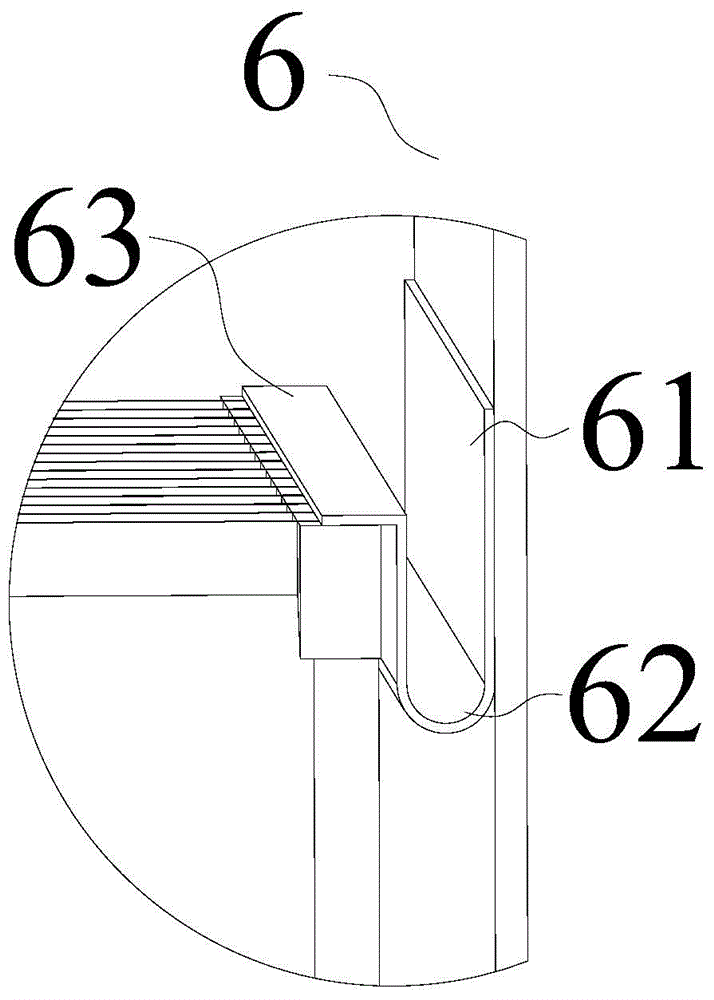

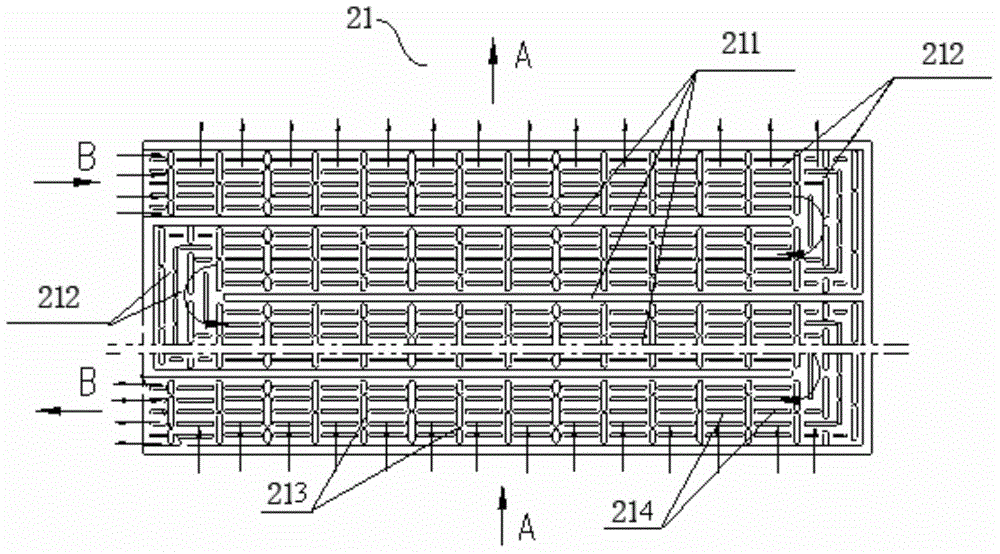

[0025] like Figure 1-3 Shown, a kind of plate type low temperature economizer of the present invention, it comprises:

[0026] The shell 1 has a smoke inlet channel 4 and a smoke exhaust channel 3 at its upper and lower ends. The smoke inlet channel 4 is composed of an inlet flange 41 and a smoke inlet guide tube 42. The smoke exhaust channel 3 is guided by an outlet flange 31 and a smoke exhaust channel. tube 32, the inner walls of the smoke guide tube 42 and the smoke guide tube 32 are provided with a smoke guide slope, such as figure 1 As shown, the smoke inlet guide cylinder 42 and the smoke exhaust guide cylinder 32 can be a shell with a round mouth and a square bottom with a taper or a conical cylindrical shell; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com