Electronic delay magneto electric detonator controller and control method thereof

A controller and detonator technology, used in electric fuzes, weapon accessories, fuzes, etc., can solve the problems of complex production process, poor safety in production links, hidden dangers, etc., and achieve high delay accuracy, improved reliability and online detection functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples. The following examples are only several specific embodiments of the present invention, but the design concept of the present invention is not limited thereto, and any non-substantial changes to the present invention by using this concept should belong to the act of violating the protection scope of the present invention.

[0023] The following circuits are conventional circuits in this field unless otherwise specified.

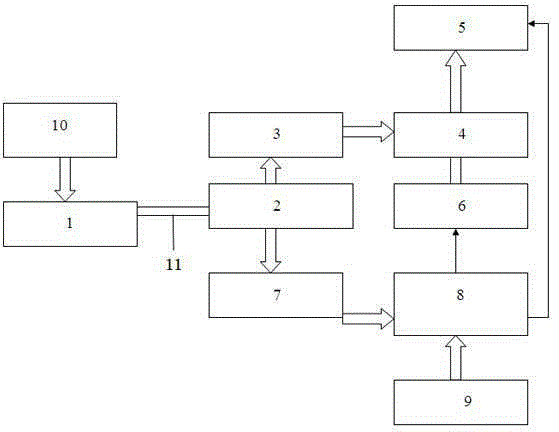

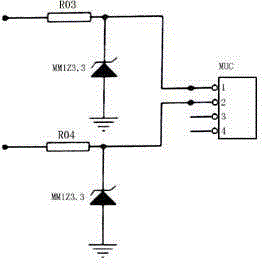

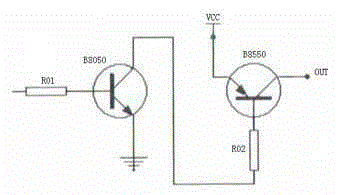

[0024] Such as figure 1 As shown, the electronic delay magnetoelectric detonator controller of the present invention has the following structure: the signal output end of the detonator 10 is connected with the input end of the electromagnetic electric energy conversion unit 1, and the electromagnetic electric energy conversion unit 1 is connected to the thunderbolt through the detonator foot wire 11. The pin line polarity judgment unit 2 is connected, the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com