High precision, wide range and large working distance laser auto-collimation device and method

A working distance and self-collimation technology, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems that self-collimation and micro-angle measurement cannot be realized, the reflected beam deviates from the entrance pupil, and the range cannot be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0086] This embodiment is an embodiment of a laser self-collimation device with high precision, wide range and large working distance.

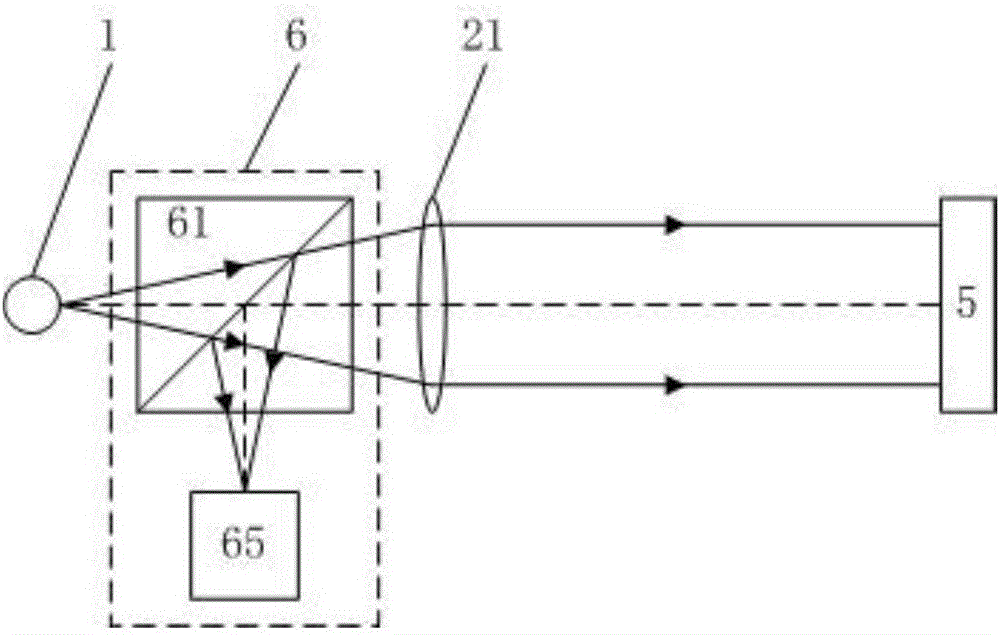

[0087] A high-precision, wide-range and large working distance laser self-collimation device in this embodiment, the schematic structural diagram is as follows figure 2 shown. The self-collimation device includes a light source 1, a transmissive collimating mirror 21, a reflector 3, and a feedback imaging system 6. The reflector 3 is provided with an angle adjustment measuring device 4; the light beam emitted from the light source 1 passes through the transmissive collimator. After the straight mirror 21 is collimated into a parallel beam, it is reflected by the mirror 3 and incident on the surface of the object to be measured 5; the beam reflected from the surface of the object to be measured 5 is reflected by the mirror 3 and then collected by the feedback imaging system 6 imaging;

[0088] The feedback imaging system 6 includes an image...

specific Embodiment 2

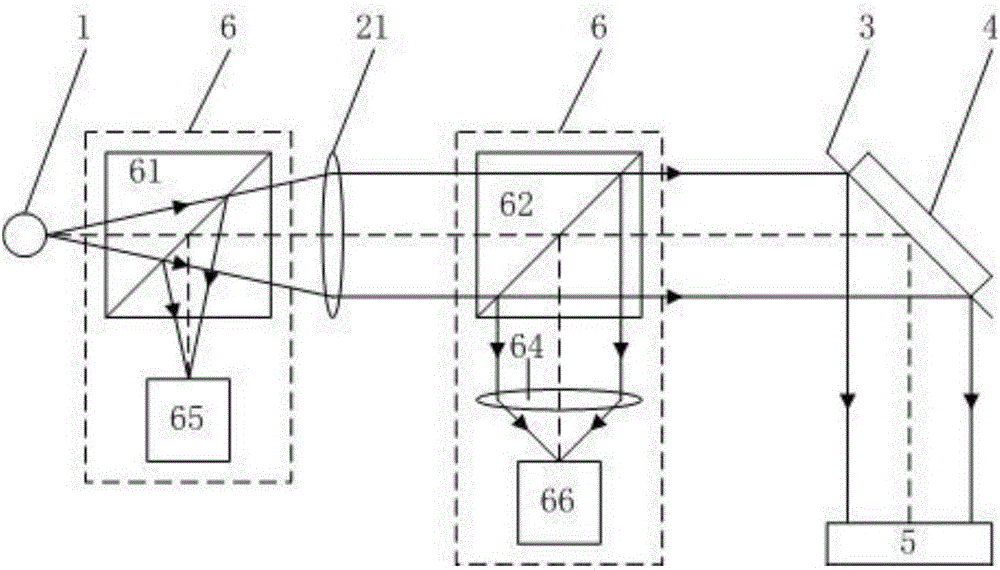

[0096] This embodiment is an embodiment of a laser self-collimation device with high precision, wide range and large working distance.

[0097] A high-precision, wide-range and large working distance laser self-collimation device in this embodiment is different from the specific embodiment 1 in the structure of the feedback imaging system 6; the structure of the feedback imaging system 6 in this embodiment is in the following two forms one of:

[0098] First, the feedback imaging system 6 includes a first feedback beam splitter 61, an image sensor 65 and a four-quadrant detector 66 carried by a guide rail 68, such as Image 6 The guide rail 68 has two pause positions, one pause position makes the image plane center of the image sensor 65 correspond to the focal position of the transmissive collimating mirror 21, and the other pause position makes the image plane center of the four-quadrant detector 66 correspond to the transmissive type the focal position of the collimating m...

specific Embodiment 3

[0101] This embodiment is an embodiment of a laser self-collimation device with high precision, wide range and large working distance.

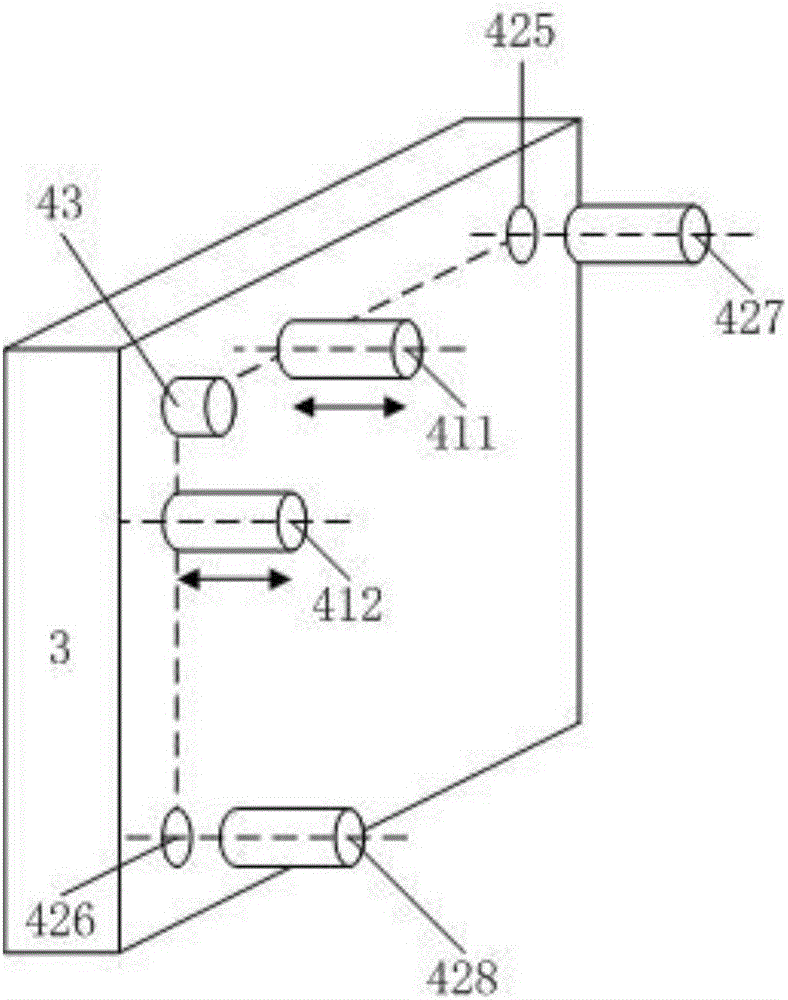

[0102] A high-precision, wide-range and large working distance laser self-collimation device in this embodiment, the schematic structural diagram is as follows Figure 8 shown. On the basis of the specific embodiment 1, a high-precision, wide-range and large working distance laser auto-collimation device in this embodiment is further provided with a wavefront detection system 7 and a wavefront compensation system 8;

[0103] The wavefront detection system 7 includes a wavefront detection spectroscope 71 and an air disturbance wavefront detector 72; the wavefront detection spectroscope 71 is arranged between the reflection mirror 3 and the measured object 5, and the air disturbance wavefront detector 72 is arranged on the reflected light path of the wavefront detection beam splitter 71, and the mirror deformation wavefront detector 73 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com