Dry thin-film condenser applied in pulse filtering field

A film capacitor, pulse dust removal technology, applied in the direction of film/thick film capacitors, capacitors, fixed capacitors, etc., can solve the problems of unfavorable equipment such as stable and reliable operation, large volume and weight, and inability to meet charging and discharging, so as to solve the problem of insufficient voltage, The effect of high charge and discharge frequency and enhanced pulse current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

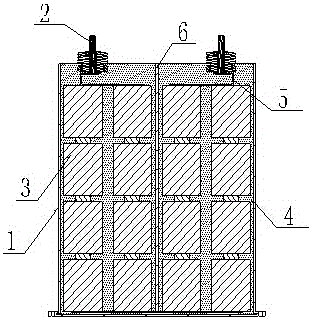

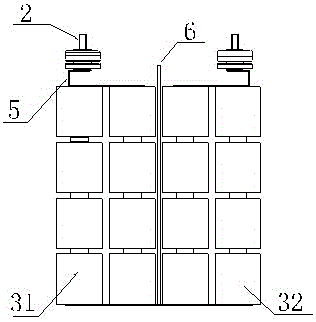

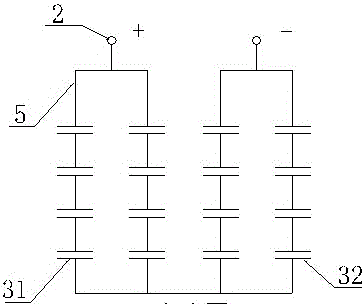

[0019] See figure 1 , figure 2 , image 3 , Figure 4 As shown, a dry film capacitor applied to the field of pulse dust removal includes a casing 1, a potting material 4 is arranged in the casing 1, a left core group 31 and a right core group 32, the left core group An insulating plate 6 is arranged between the subgroup 31 and the right core group 32, so that the left core group and the right core group are separated to increase the creepage distance, and the left core group 31 and the right core group 32 Both are connected to the electrodes 2 by welding the copper plate 5. The left core group 31 and the right core group 32 respectively include two sets of single core groups connected and welded. The single core group is composed of four capacitor cores 3 connected in series. The capacitor core 3 includes at least ten series of metallized films 7, the left core group 31 and the right core group 32 are connected in series, the metallized film 7 of the capacitor core 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com