Omni-bearing machining mortise and tenon joint making machine and implementation method thereof

A mortise and tenon machine, an all-round technology, applied in the production of tongue or groove, etc., can solve the problems of difficult processing precision, high processing cost, high labor intensity, etc., to save later maintenance costs, save tool costs, The effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

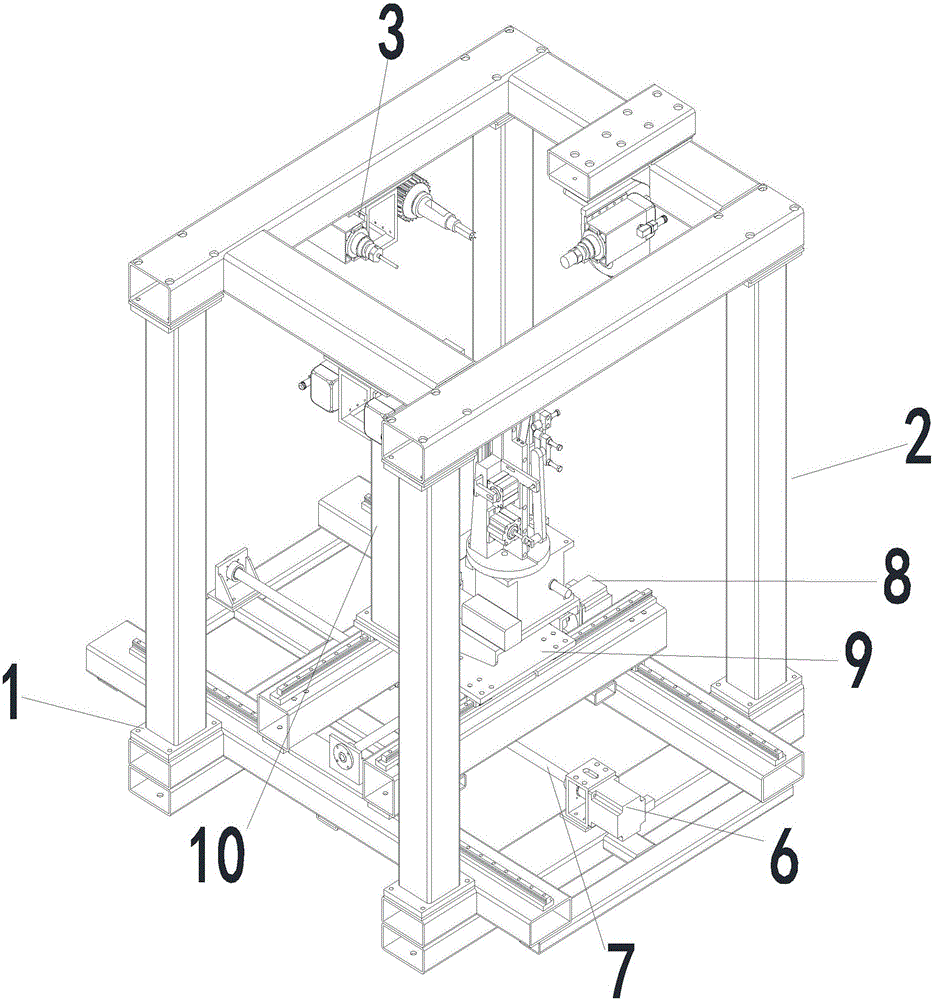

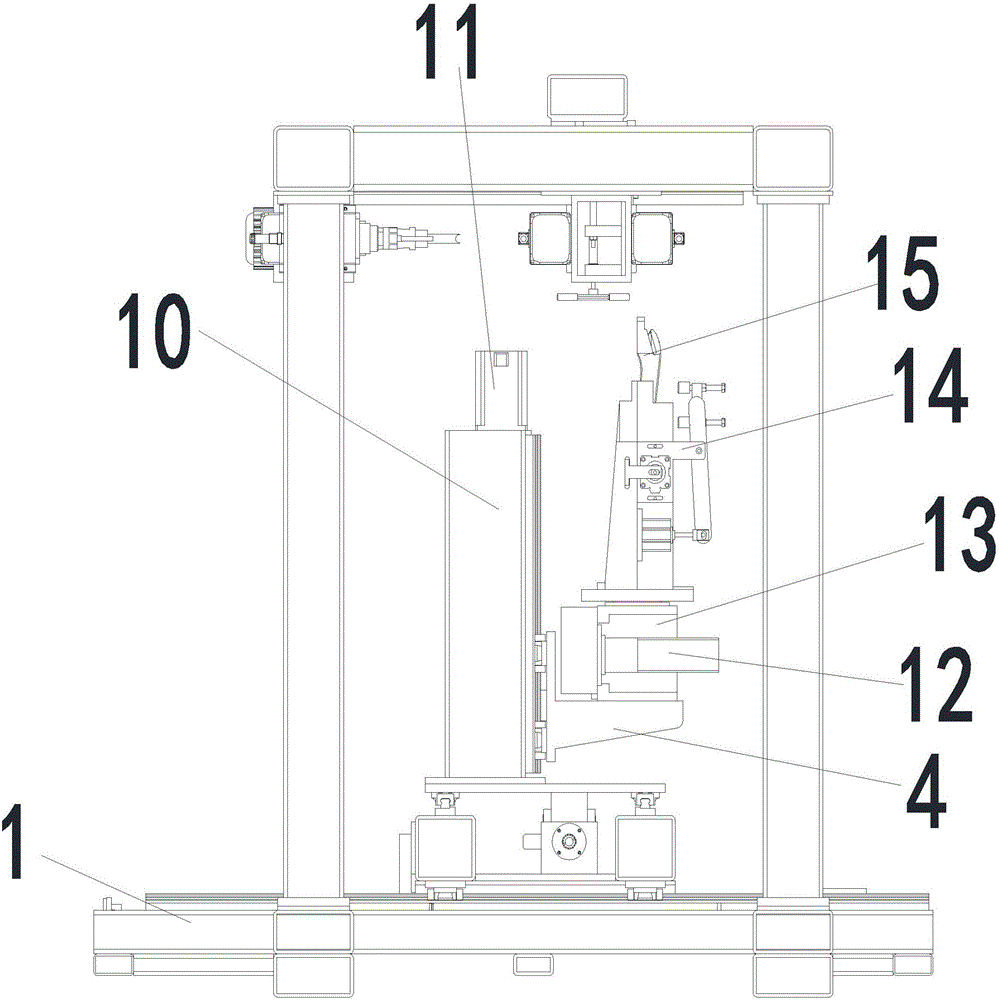

[0035] Such as Figure 1~2 As shown, a mortise and tenon machine for all-round processing includes a base, and supporting columns are connected around the base. There is only a horizontal moving device, the horizontal moving device is provided with a vertical moving device, the vertical moving device is provided with a vertical moving device, the vertical moving device is connected with the processing base, the processing base is provided with a workpiece clamping mechanism, and the controller is respectively connected with the processing The cutter, the longitudinal moving device, the horizontal moving device and the vertical moving device are connected.

[0036] In this embodiment, the lower surface of the upper motor base is provided with different numbers of machining tools through the motor support base.

[0037] The lateral movement device in the present embodiment comprises a transverse motor, and the transverse motor drives a transverse screw mandrel, which is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com