Environment-friendly and pollution-free novel organic compounded phosphate fertilizer production technology

A non-polluting, organic technology, applied in the direction of organic phosphate fertilizer, phosphate fertilizer, dicalcium phosphate fertilizer, etc., can solve the problems of high environmental pressure of waste disposal, insufficient utilization of pot ash, and high waste utilization rate, to maintain food security and promote industrial sustainability. The effect of sustainable development, beneficial to energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

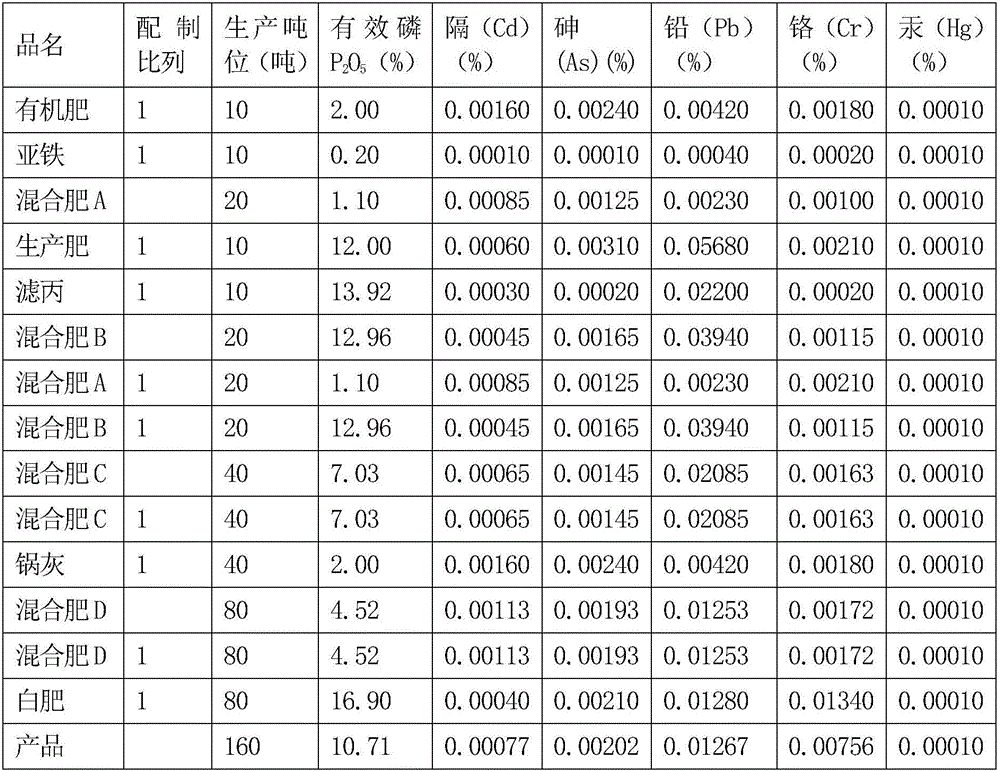

[0039] A kind of environment-friendly and pollution-free novel organic mixed phosphorus fertilizer production process, it comprises the following steps:

[0040] A, mix 10 tons of organic fertilizers with 10 tons of ferrous sulfate, get 20 tons of mixed fertilizer A;

[0041] B, 10 tons of production fertilizers are mixed with 10 tons of filter acrylic, and 20 tons of mixed fertilizers B are obtained;

[0042] c. Mix 20 tons of mixed fertilizer A with 20 tons of mixed fertilizer B to obtain 40 tons of mixed fertilizer C;

[0043] d. Mix 40 tons of mixed fertilizer C and 40 tons of pot ash evenly to get 80 tons of mixed fertilizer D;

[0044] e. Mix 80 tons of mixed fertilizer D and 80 tons of white fertilizer evenly to obtain 160 tons of finished product.

[0045] Wherein, the production of superphosphate (production fertilizer) is according to the following method: 7 tons of phosphate rocks with a content of 24% are added with water and ball-milled into a moisture content o...

Embodiment 2

[0050] A kind of environment-friendly and pollution-free novel organic mixed phosphorus fertilizer production process, it comprises the following steps:

[0051] A, 20 tons of organic fertilizers are mixed with 18 tons of ferrous sulfate, get 38 tons of mixed fertilizer A;

[0052] B, 20 tons of production fertilizers are mixed with 20 tons of filter acrylic, get 40 tons of mixed fertilizers B;

[0053] c. Mix 38 tons of mixed fertilizer A with 40 tons of mixed fertilizer B to get 78 tons of mixed fertilizer C;

[0054] d. Mix 78 tons of mixed fertilizer C with 80 tons of pot ash to get 158 tons of mixed fertilizer D;

[0055] e, 158 tons of mixed fertilizer D and 150 tons of white fertilizer are evenly mixed to obtain 308 tons of finished product.

[0056] Wherein, the production of superphosphate (production fertilizer) is according to the following method: 14 tons of phosphate rock with a content of 24% is added with water and ball-milled into a water content of 28%, an...

Embodiment 3

[0059] A kind of environment-friendly and pollution-free novel organic mixed phosphorus fertilizer production process, it comprises the following steps:

[0060] A, 10 tons of organic fertilizers are mixed with 8 tons of ferrous sulfate, get 18 tons of mixed fertilizer A;

[0061] B, 10 tons of production fertilizers are mixed with 9 tons of filter acrylic, and 19 tons of mixed fertilizers B are obtained;

[0062] c. Mix 18 tons of mixed fertilizer A with 19 tons of mixed fertilizer B to get 37 tons of mixed fertilizer C;

[0063] d. Mix 37 tons of mixed fertilizer C with 40 tons of pot ash to get 78 tons of mixed fertilizer D;

[0064] e. Mix 78 tons of mixed fertilizer D and 72 tons of white fertilizer evenly to obtain 150 tons of finished product.

[0065] Wherein, the production of superphosphate (production fertilizer) is according to the following method: 7 tons of phosphate rocks with a content of 24% are added with water and ball-milled into a moisture content of 28%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com