A kind of plant hollow capsule tailings redissolving method

A technology for plant hollow capsules and tailings, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of the industrialization of plant hollow capsules, the inability to large-scale production and popularization of the market, and the inability to re-dissolve and reuse the tailings. Achieve the effect of strong industrialization implementation, reduce raw material consumption and unit production cost, and save transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

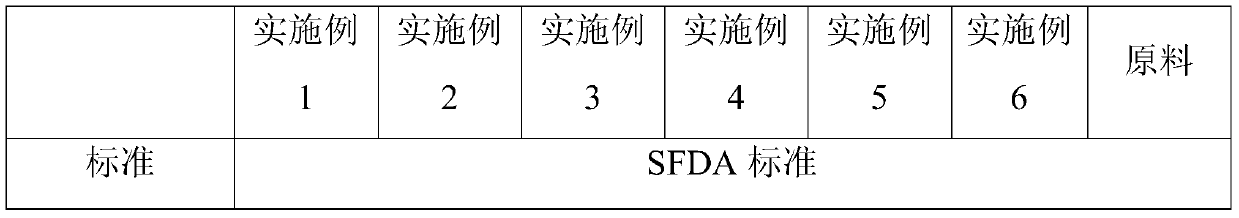

Examples

Embodiment 1

[0045] 1), weighing: 14kg of plant hollow capsule tailings, 86kg of purified water, and 0.28kg of titanium dioxide.

[0046] 2) Stirring by raising the temperature: add 86kg of purified water into the sol tank and heat up to 90°C, then turn on the stirring motor, then slowly add 14kg of plant hollow capsule tailings into the sol tank, and stir for 1 hour until the mixture is uniform.

[0047] 3) Cooling and stirring: Open the cooling water inlet valve and outlet valve of the sol tank, adjust the flow rate, and slowly lower the temperature of the material liquid in the second step above to 35°C, and stir evenly.

[0048] 4) Stirring at constant temperature: keep the temperature of the feed liquid at 35°C, and stir at a constant temperature for 0.5 hours until the feed liquid is completely dissolved into a uniform glue, that is, the surface of the glue is shiny and there are no tailing particles.

[0049] 5), heating and coloring: when the temperature of the glue solution is rai...

Embodiment 2

[0053] 1) Weighing: 20kg of plant hollow capsule tailings, 80kg of purified water, 0.4kg of titanium dioxide, and 0.08kg of bright blue pigment.

[0054]2) Stirring by raising the temperature: Add 80kg of purified water into the sol tank and heat up to 95°C, then turn on the stirring motor, then slowly add 20kg of plant hollow capsule tailings into the sol tank, and stir for 3 hours until the mixture is uniform.

[0055] 3) Cooling and stirring: Open the cooling water inlet valve and outlet valve of the sol tank, adjust the flow rate, and slowly lower the temperature of the material liquid in the second step above to 40°C, and stir evenly.

[0056] 4) Stirring at constant temperature: Keep the temperature of the feed liquid at 40°C and stir for 2 hours at a constant temperature until the feed liquid is completely dissolved into a uniform glue, that is, the surface of the glue is shiny and there are no tailing particles.

[0057] 5), heating and coloring: when the temperature o...

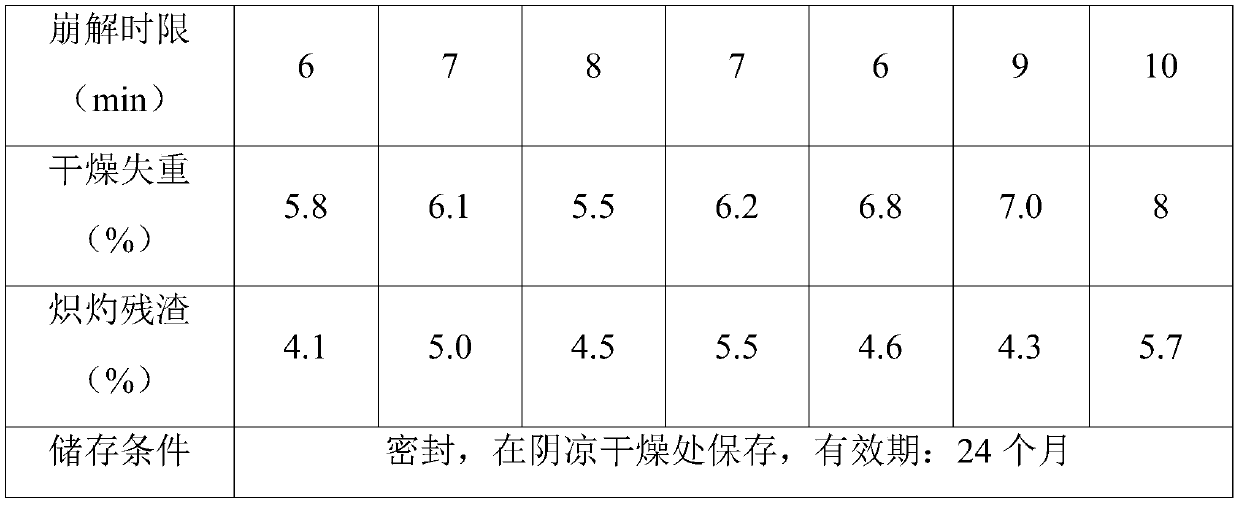

Embodiment 3

[0061] 1), weighing: 17kg of plant hollow capsule tailings, 83kg of purified water, 0.34kg of titanium dioxide, and 0.07kg of fruit green pigment.

[0062] 2) Stirring by raising the temperature: Add 83kg of purified water into the sol tank and heat up to 92°C, then turn on the stirring motor, then slowly add 17kg of plant hollow capsule tailings into the sol tank, and stir for 2 hours until the mixture is uniform.

[0063] 3) Cooling and stirring: Open the cooling water inlet valve and outlet valve of the sol tank, adjust the flow rate, and slowly lower the temperature of the material liquid in the second step above to 38°C, and stir evenly.

[0064] 4) Stirring at constant temperature: keep the temperature of the feed liquid at 38°C, and stir at a constant temperature for 1 hour until the feed liquid is completely dissolved into a uniform glue, that is, the surface of the glue is shiny and there are no tailing particles.

[0065] 5), heating up and toning: when the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com